A kind of sulfur/polypyrrole/graphene/carbon nanotube composite film, preparation method and application thereof

A carbon nanotube composite and graphene composite technology, applied in the direction of positive electrodes, active material electrodes, structural parts, etc., can solve the problems of complex and time-consuming processes, and achieve improved rate performance, improved cycle stability, and increased charging and discharging. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

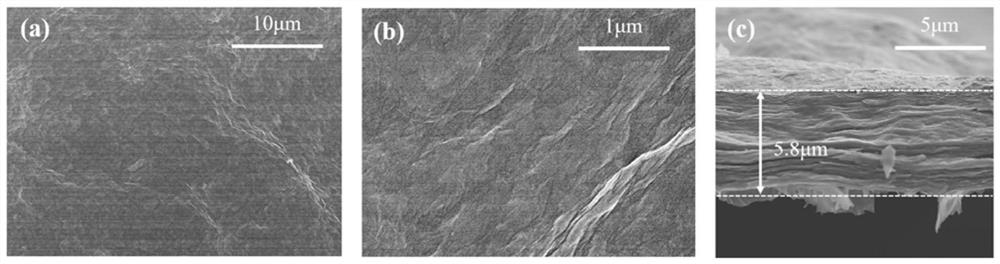

[0080] A high-performance lithium-sulfur battery cathode material, the material includes sulfur / polypyrrole / graphene / carbon nanotube composites, the steps of the technical solution adopted in this embodiment are as follows:

[0081] 1) the preparation of graphene oxide is the same as step 1 in comparative example 1);

[0082] 2) Purification and acidification of carbon nanotubes are the same as step 2 in Comparative Example 2);

[0083] 3) Preparation of polypyrrole / graphene / carbon nanotube composite film (PCG):

[0084] Add 5.6mL of the graphene oxide aqueous solution prepared in step 1) to 200mL of ethanol and deionized water mixed solution (the volume ratio of ethanol and deionized water is 1:1), ultrasonically disperse at a frequency of 100kW for 1h; add 2.8mL of pyrrole, After stirring evenly, it was aged at room temperature for three days, and the color of the solution changed from brownish yellow to brownish black to obtain a mixed suspension of polypyrrole / graphene; 0...

Embodiment 2

[0095] A high-performance lithium-sulfur battery cathode material, the material includes sulfur / polypyrrole / graphene / carbon nanotube composites, the steps of the technical solution adopted in this embodiment are as follows:

[0096] 1) the preparation of graphene oxide is the same as step 1 in comparative example 1);

[0097] 2) Purification and acidification of carbon nanotubes are the same as step 2 in Comparative Example 2);

[0098] 3) Preparation of polypyrrole / graphene / carbon nanotube composite film (PCG):

[0099] Add 5.6mL of the graphene oxide aqueous solution prepared in step 1) to 300mL of the mixed solution of ethanol and deionized water (the volume ratio of ethanol and deionized water is 1:2), ultrasonicate at a frequency of 100kW for 2h; add 5.6mL of pyrrole, and stir well Afterwards, aging at room temperature for 48h, the solution color changes from brownish yellow to brownish black to obtain a polypyrrole / graphene mixed suspension; in the above suspension, add...

Embodiment 3

[0105] A high-performance lithium-sulfur battery cathode material, the material includes sulfur / polypyrrole / graphene / carbon nanotube composites, the steps of the technical solution adopted in this embodiment are as follows:

[0106] 1) the preparation of graphene oxide is the same as step 1 in comparative example 1);

[0107] 2) Purification and acidification of carbon nanotubes are the same as step 2 in Comparative Example 2);

[0108] 3) Preparation of polypyrrole / graphene / carbon nanotube composite film (PCG):

[0109]Add 5.6mL of the graphene oxide aqueous solution prepared in step 1) to 300mL of the mixed solution of ethanol and deionized water (the volume ratio of ethanol and deionized water is 2:1), ultrasonically disperse at a frequency of 100kW for 0.5h; add 0.56mL of pyrrole , after stirring evenly, aging at room temperature for three days, the color of the solution changes from brownish yellow to brownish black to obtain a polypyrrole / graphene mixed suspension; add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com