Method for improving performance of MoS2 gas sensor by adopting W doping

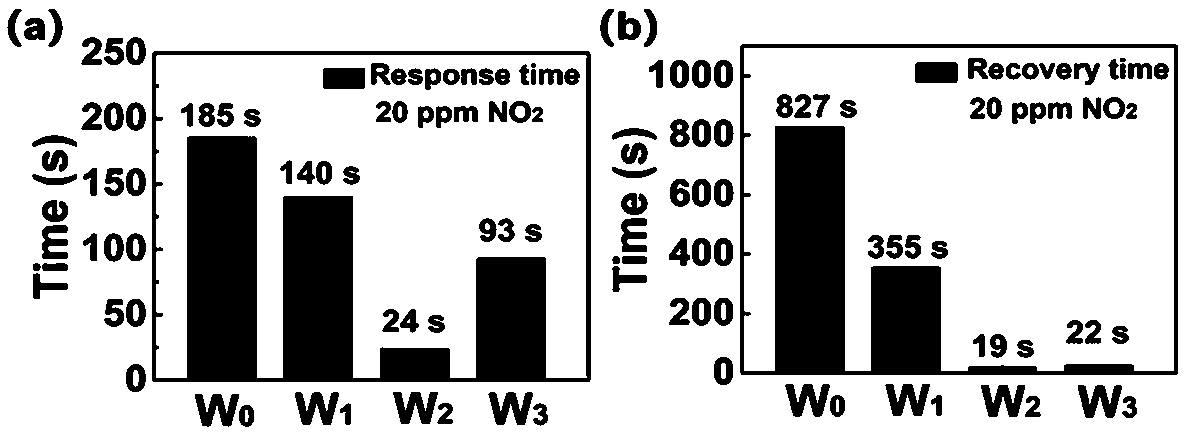

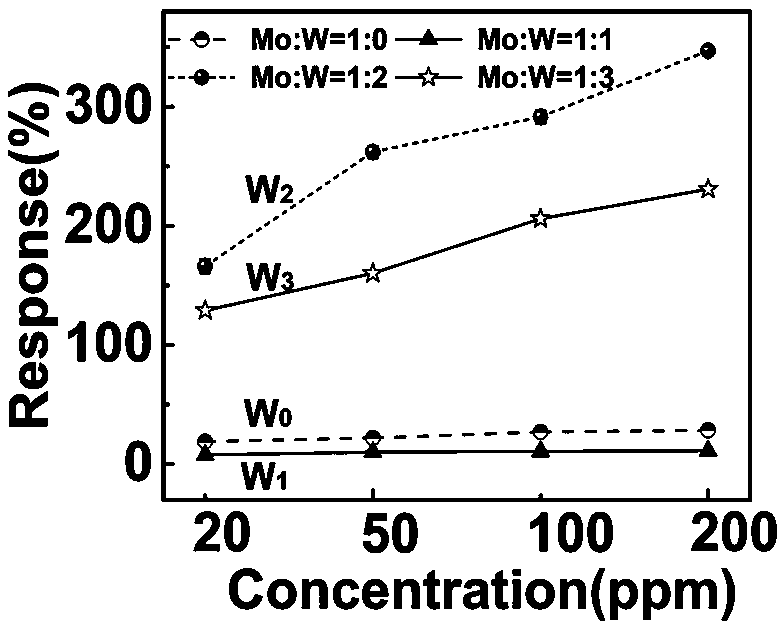

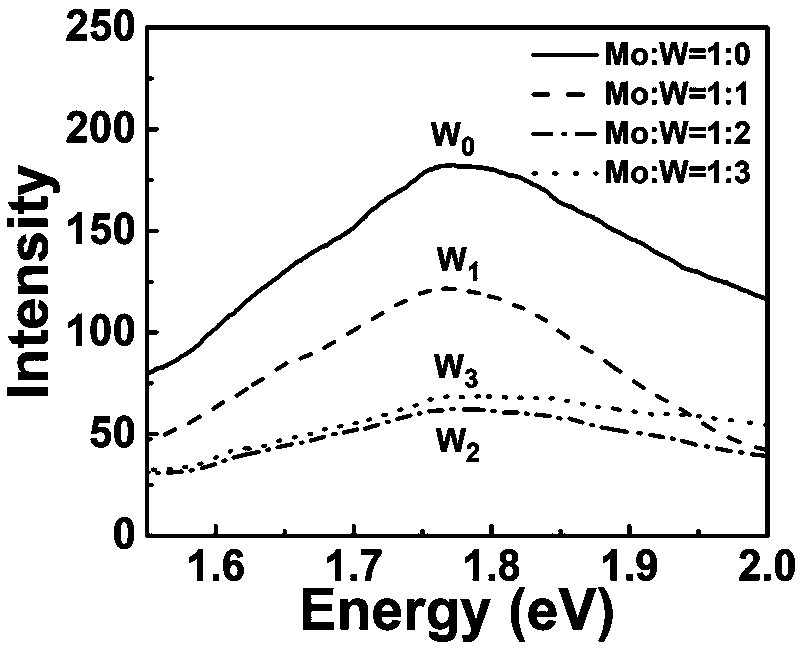

A gas sensor and performance technology, applied in chemical instruments and methods, instruments, scientific instruments, etc., can solve the problems that hinder the practical application of MoS2, slow response/recovery time, difficult desorption, etc., to overcome the long response/recovery time. , the effect of reduced response/recovery time and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] W-doped MoS with a Mo / W molar ratio of 1:2 2 As a sensitive material to make a planar interdigitated gas sensor, the specific manufacturing process is as follows:

[0038] ① Weigh 1.21 g sodium molybdate (5 mmol), 1.127 g ammonium thioacetate (15 mmol), and 3.30 g sodium tungstate (10 mmol) into a beaker, add 30 mL deionized water, and stir with a magnetic stirrer 25 minutes to dissolve;

[0039] ② Add 0.3 g sodium silicate to the above mixed solution to promote W doping MoS 2 the formation of materials;

[0040] ③Put dilute hydrochloric acid (2 mol / L) dropwise into the above solution, and adjust the pH value of the transparent solution to about 6;

[0041] ④Transfer the above homogeneous solution into a polytetrafluoroethylene liner with a volume of 150 mL, then put the liner into a stainless steel reaction kettle, seal the reaction kettle, put it in an oven and heat it for reaction at 200°C for 24 hours ;

[0042] ⑤ After the reaction kettle is naturally cooled, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com