Working condition variable water spraying cooling device for high-temperature fuel gas

A technology of water spray cooling and water inlet device, which is applied in the direction of spray device, spray device, household refrigeration device, etc., can solve the problems of slow cooling response, complicated device structure design, equipment burning loss, etc., to reduce the loss of gas heat, Save test costs and enhance the effect of control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

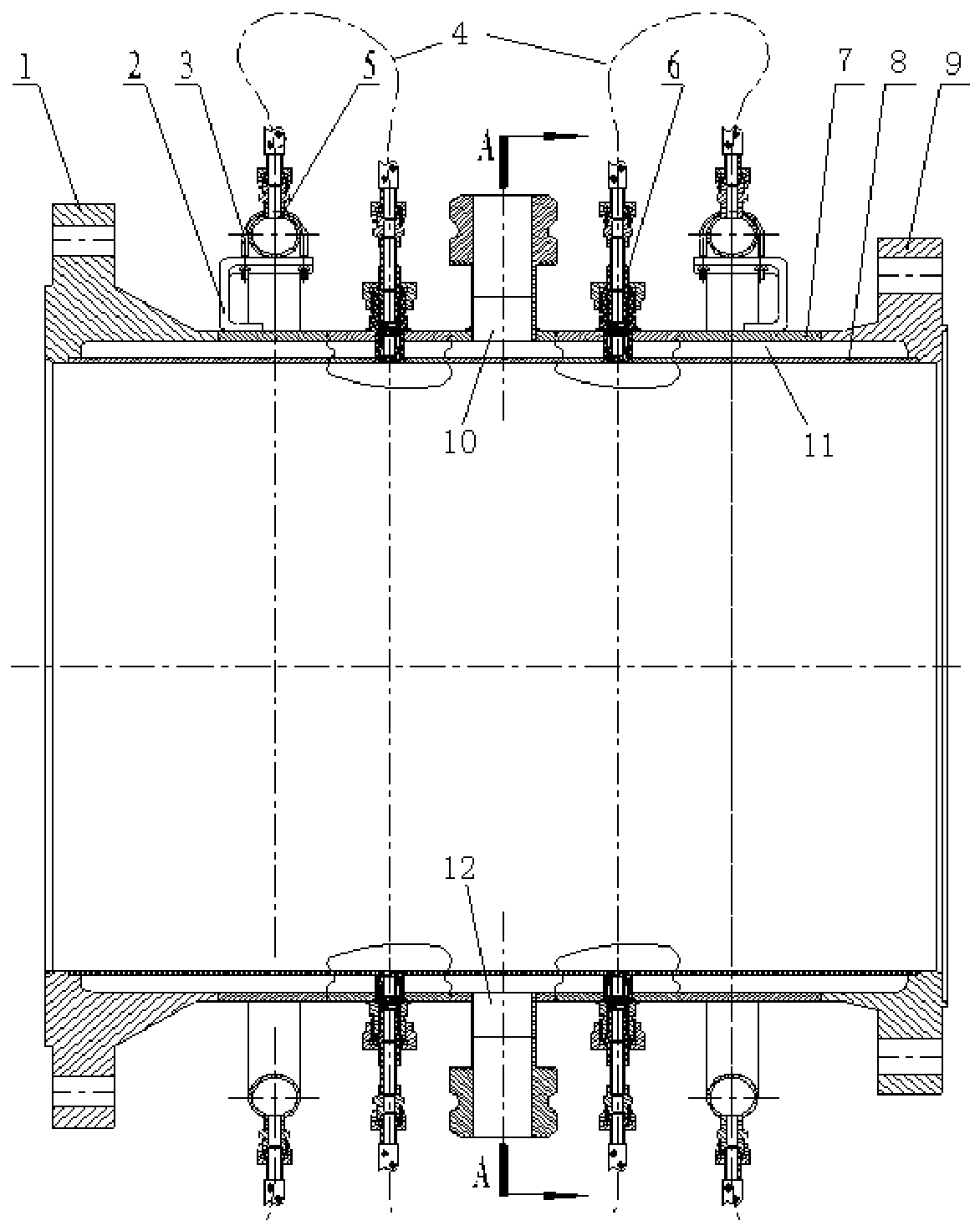

[0021] The present invention will be further introduced below in conjunction with the accompanying drawings. A variable-condition water spray cooling device for high-temperature gas according to the present invention includes an inner cylinder 7, an outer cylinder 8, a pipeline inlet flange 1, Pipeline outlet flange 9, several replaceable nozzle structures 6, several high-pressure water inlet devices 5, the inner cylinder 7 and the outer cylinder 8 are circular pipes (square and fan-shaped can also be designed according to needs), the pipes The inner ring of the pipeline inlet flange 1 and the pipeline outlet flange 9 is a groove structure, and the end faces of the grooves with large and small diameters are respectively welded with the inner cylinder 7 and the outer cylinder 8 to form an annular cavity 11. The bottom and top of the annular cavity 11 are respectively provided with a water jacket water inlet pipe 12 and a water jacket outlet pipe 10 connected thereto. It fills t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com