Fuel atomizing nozzle adopting single-electrode plasma jet flow and control method of fuel atomizing nozzle

A plasma and fuel atomization technology, applied in combustion methods, combustion chambers, combustion equipment, etc., can solve the problems of loss of activity, low reliability, poor atomization enhancement, etc., to improve reaction activity, reduce production costs, Improve the effect of distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to understand the above-mentioned purpose, features and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

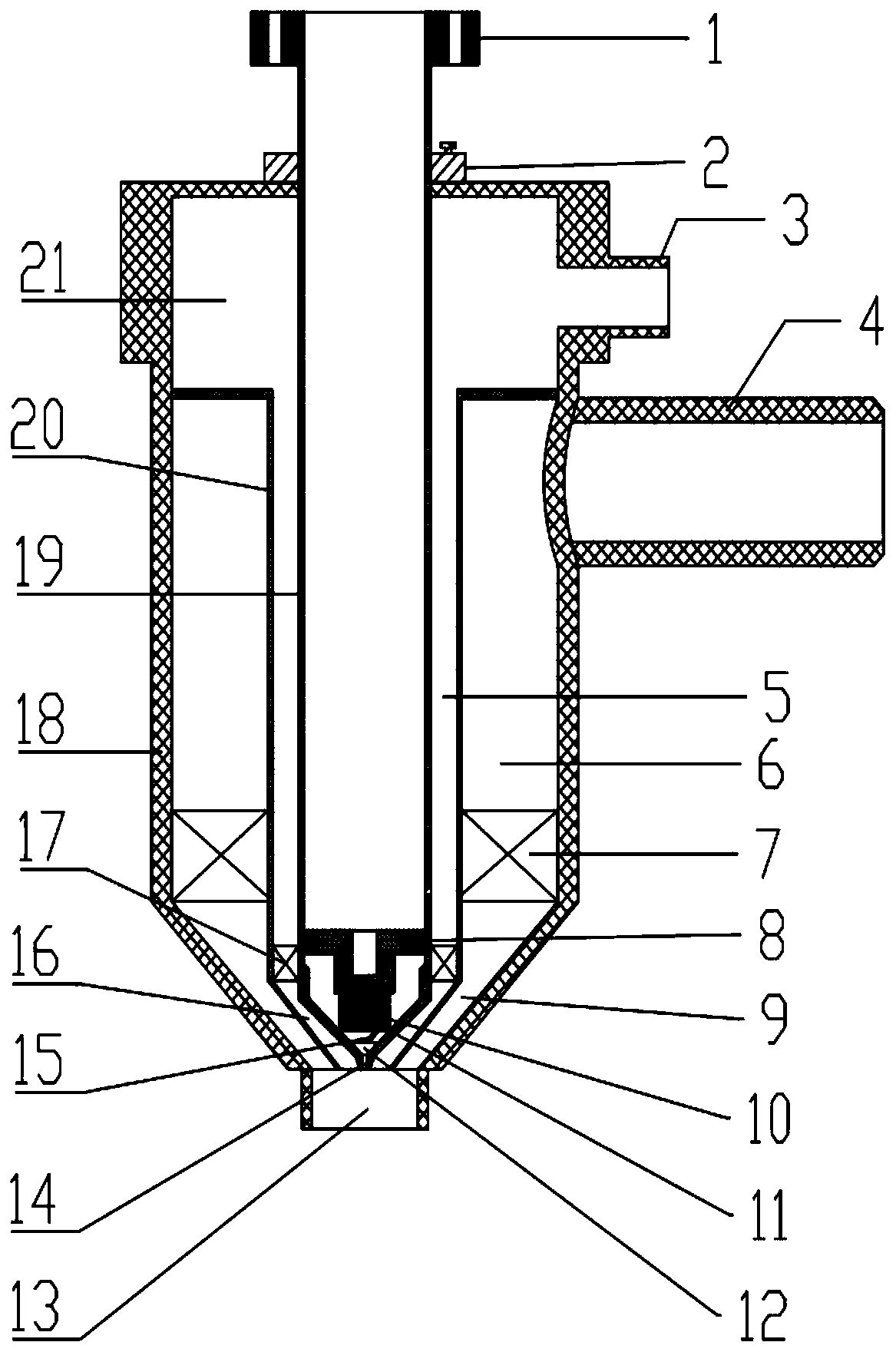

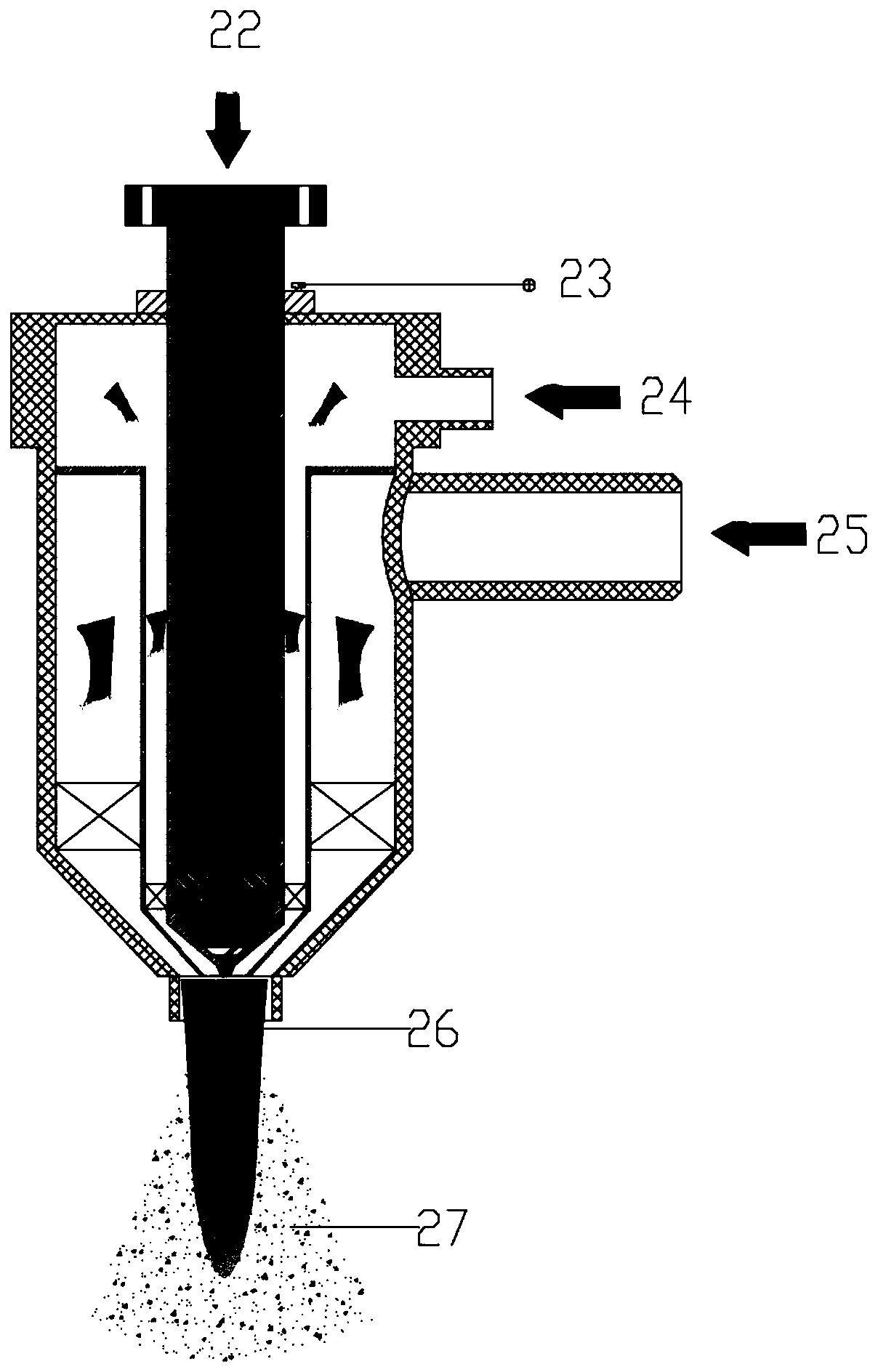

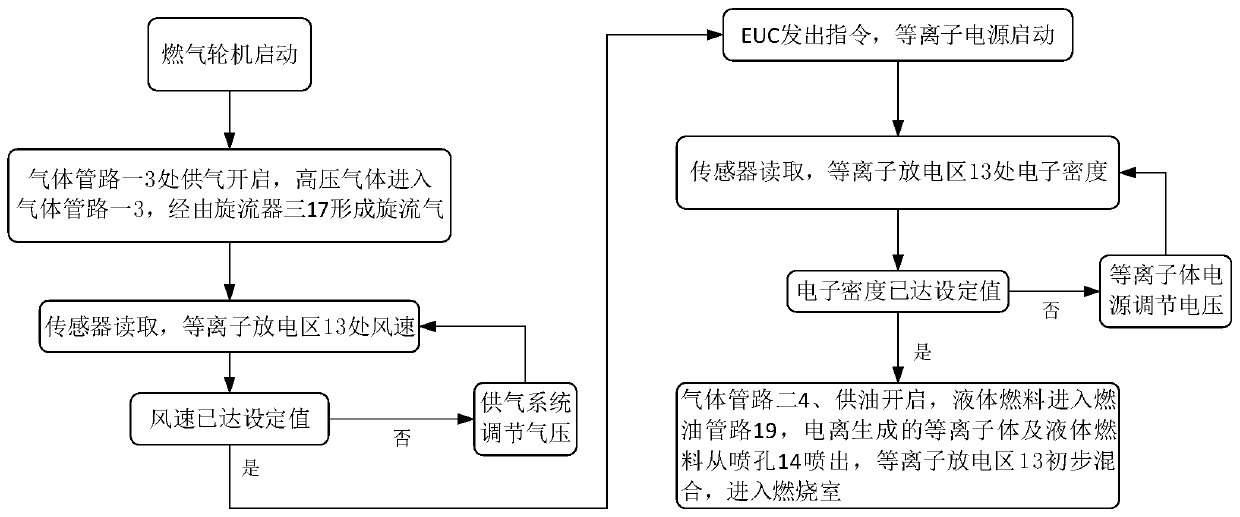

[0036] Refer below Figure 1-3 A fuel atomization nozzle using a single-electrode plasma jet and a control method provided according to an embodiment of the present invention will be described.

[0037] Such as figure 1 As shown, the present invention includes an injector, an insulating flange 1, an insulating housing 18, a high-voltage electrode connector 2, a fuel pipeline 19, a cyclone one 7, a cyclone chamber one 9, a cyclone three 17, a cyclone Room 3 16, gas pipeline, plasma discharge area 13, cavity, wherein the injector includes: oil filter positioner 8, oil filter 10, cyclone 2 15, cyclone chamber 2 12, nozzle hole 14, conical The contraction pipeline 11, the components of the injector are made of metal materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com