Method and device for recycling metal from waste lithium battery

A technology for used lithium batteries and metals, applied in battery recycling, waste collector recycling, recycling technology, etc., to achieve the effects of reducing energy consumption, improving precipitation, and simplifying separation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

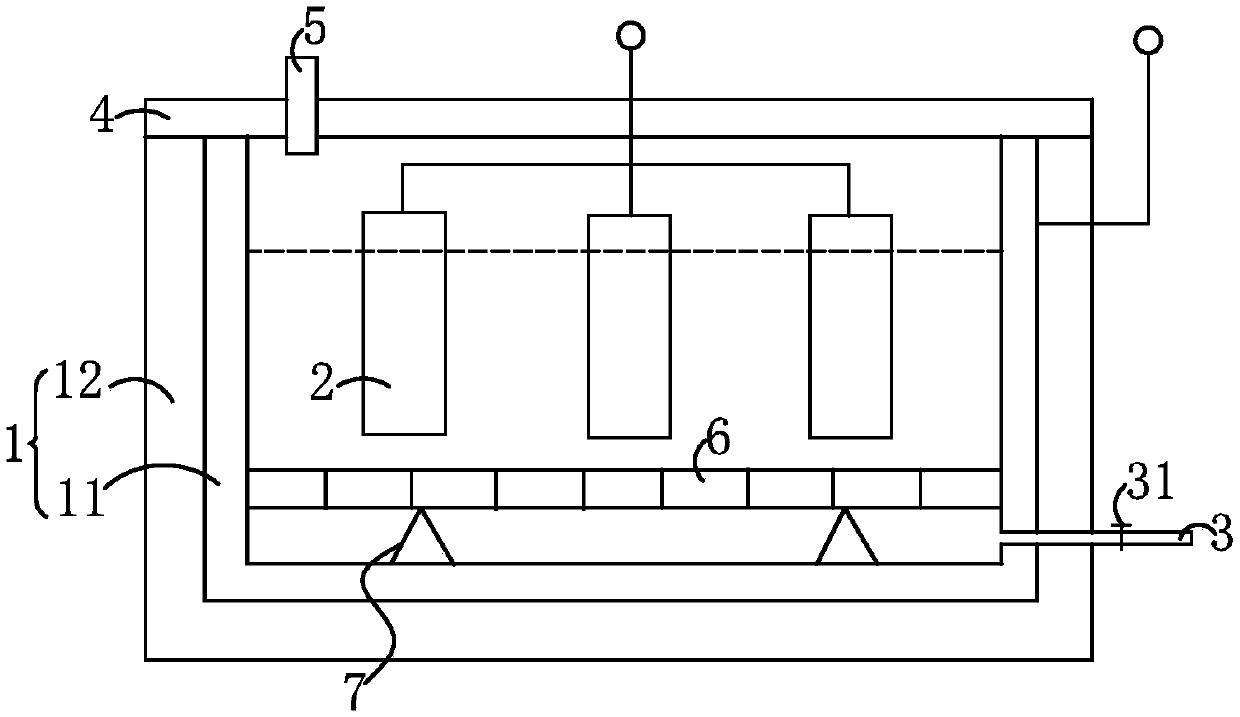

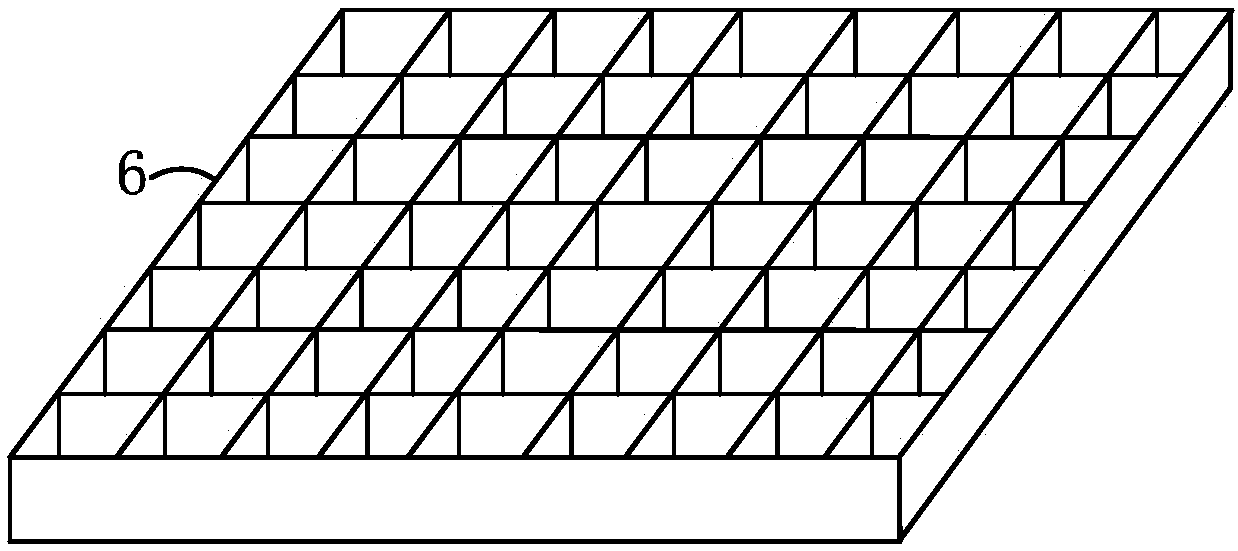

[0045] The present embodiment provides a method for recycling metals from waste lithium batteries, the method comprising the following steps:

[0046] The positive electrode material of the waste lithium battery is used as the cathode, and the graphite electrode is used as the anode; wherein, the manufacturing method of the cathode is as follows: the positive electrode material of the waste lithium battery is taken, disassembled, calcined, washed, dried, ground, and pressed to form, and the cathode and the cathode are obtained. The thickness of the electrode is 5mm, and the compacted density of the cathode is 5g / cm 3 .

[0047] Put the cathode and anode into the ammonium carbonate electrolyte with a concentration of 0.1moL / L for electrochemical reaction. The applied potential of the electrochemical reaction is 0.2-1.5V, and the applied potential value is adjusted from large to small. The time is 2 hours, and the mixed solution containing the recovered metal ions is obtained, ...

Embodiment 2

[0055] The present embodiment provides a method for recycling metals from waste lithium batteries, the method comprising the following steps:

[0056] The positive electrode material of the waste lithium battery is used as the cathode, and the platinum electrode is used as the anode; the manufacturing method of the cathode is as follows: the positive electrode material of the waste lithium battery is taken, disassembled, calcined, washed, dried, ground, and pressed in sequence to obtain the cathode and the cathode The thickness of the electrode is 10mm, and the compaction density of the cathode is 10g / cm 3 .

[0057] Put the cathode and anode into the ammonium sulfate electrolyte with a concentration of 1.0moL / L for electrochemical reaction, the applied potential of the electrochemical reaction is 0.2-1.4V, and the time of applying the potential is 8h, to obtain the The solutions are mixed, and the recovered metal ions are leached step by step. Specifically, adjust the appli...

Embodiment 3

[0061] The present embodiment provides a method for recycling metals from waste lithium batteries, the method comprising the following steps:

[0062] The positive electrode material of the waste lithium battery is used as the cathode, and the graphite electrode is used as the anode; wherein, the manufacturing method of the cathode is as follows: the positive electrode material of the waste lithium battery is taken, disassembled, calcined, washed, dried, ground, and pressed to form in sequence to obtain the cathode, the cathode The thickness of the electrode is 7mm, and the compacted density of the cathode is 7g / cm 3 .

[0063] Put the cathode and anode into the ammonium chloride electrolyte with a concentration of 0.5moL / L for electrochemical reaction. The potential applied for the electrochemical reaction is 0.2-1.5V, and the applied potential value is adjusted from large to small. The electric potential time is 4 hours, and a mixed solution containing recovered metal ions ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com