Method for producing concrete by using mixing station waste slag and obtained concrete

A mixing station and concrete technology, which is applied in the field of concrete production from waste slag in a mixing station, can solve the problems of untreated waste slag, high processing cost, and high energy consumption, and achieve the effects of easy control of construction time, reduction of raw material costs, and reduction of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

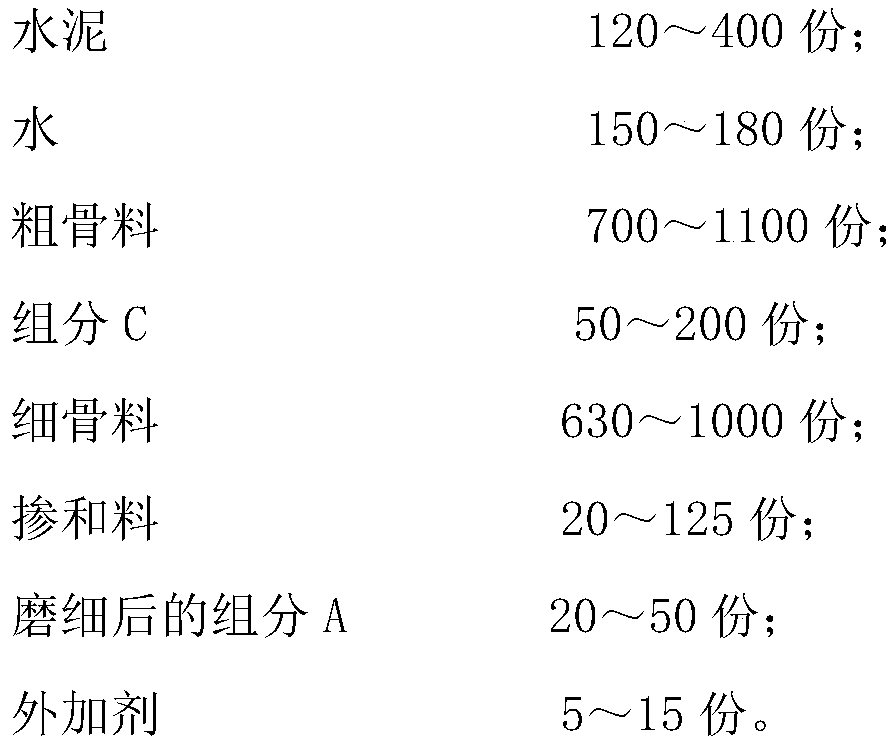

Method used

Image

Examples

Embodiment 1

[0044] Air-drying, stirring, drying, sieving, and grinding procedures are used to process the waste residue of the mixing station. The specific methods are as follows:

[0045] Naturally air-dry the waste slag from the mixing station until the water content is lower than 5wt%, and then sieve the waste slag with a particle size ≥ 70mm as component D, and the rest is waste slag with a particle size < 70mm;

[0046] The waste slag with a particle size of <70mm and the coarse aggregate are mixed and dried according to a certain ratio through a stirring dryer, so that the moisture content is lower than 2wt%, and then sieved after drying, and the slag powder with a particle size of ≤3mm is sorted out as a component A, particle size ≥ 31.5mm is component B; the rest is component C; after component B and component D are crushed, put them into the coarse aggregate bin and use them as coarse aggregate.

[0047] Component A is pulverized so that its specific surface area is 300-400m 2 / ...

Embodiment 2

[0057] Adopt the method for embodiment 1 to obtain component A and component C.

[0058] Component A is pulverized so that the specific surface area of component A is 400-500m 2 / kg.

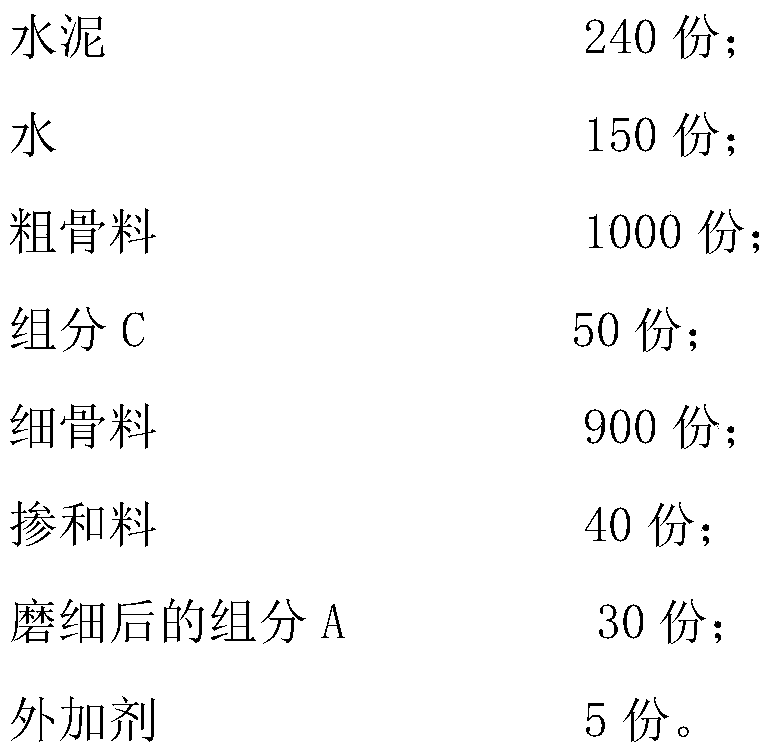

[0059] Prepare concrete (C25) as follows:

[0060] Weigh 240kg of cement, 1000kg of 5-31.5mm continuous graded crushed stone, 50kg of component C, 900kg of fine aggregate water-washed machine-made sand, 20kg of high-quality grade I fly ash as admixture, 20kg of mineral powder, and component A with a weighing scale. 30kg, mixing water 150kg, admixture polycarboxylate retarding pumping agent 5.0kg, add crushed stone, sand, cement, fly ash to the mixer in turn and mix evenly, at the same time, the admixture must first be added to the concrete mixing water Mix, then add the mixed liquid of water and admixture into the concrete mixer, and after fully stirring for 1 to 2.5 minutes, the concrete mixture is unloaded from the mixer and transported to the construction site by a concrete tank truck for...

Embodiment 3

[0064] Adopt the method for embodiment 1 to obtain component A and component C.

[0065] Component A is pulverized so that the particle size of component A is 500-600m 2 / kg.

[0066] Prepare concrete (C25) as follows:

[0067] Weigh 240kg of cement, 1000kg of 5-31.5mm continuous graded crushed stone, 50kg of component C, 900kg of fine aggregate water-washed machine-made sand, 20kg of high-quality grade I fly ash as admixture, 20kg of mineral powder, and component A with a weighing scale. 30kg, mixing water 150kg, admixture polycarboxylate retarding pumping agent 5.0kg, add crushed stone, sand, cement, fly ash to the mixer in turn and mix evenly, at the same time, the admixture must first be added to the concrete mixing water Mix, then add the mixed liquid of water and admixture into the concrete mixer, and after fully stirring for 1 to 2.5 minutes, the concrete mixture is unloaded from the mixer and transported to the construction site by a concrete tank truck for subsequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com