Alkali-free liquid accelerator and preparation method thereof

A technology of accelerator and liquid, applied in the direction of aluminum sulfur compound, aluminum sulfate, etc., can solve the problems of low solid content of saturated solution, decrease of stability of accelerator, and decrease of concrete performance, so as to achieve high solid content and improve stability , good quick-setting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

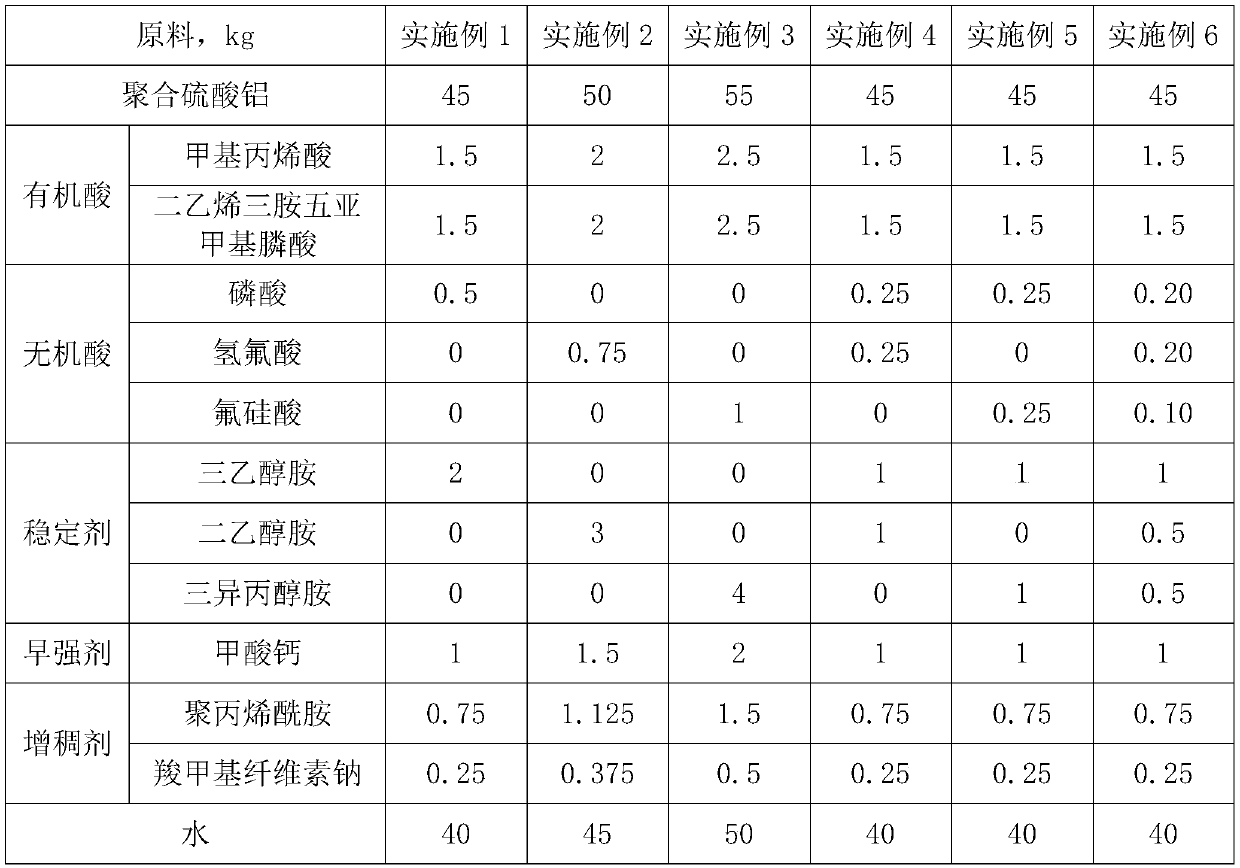

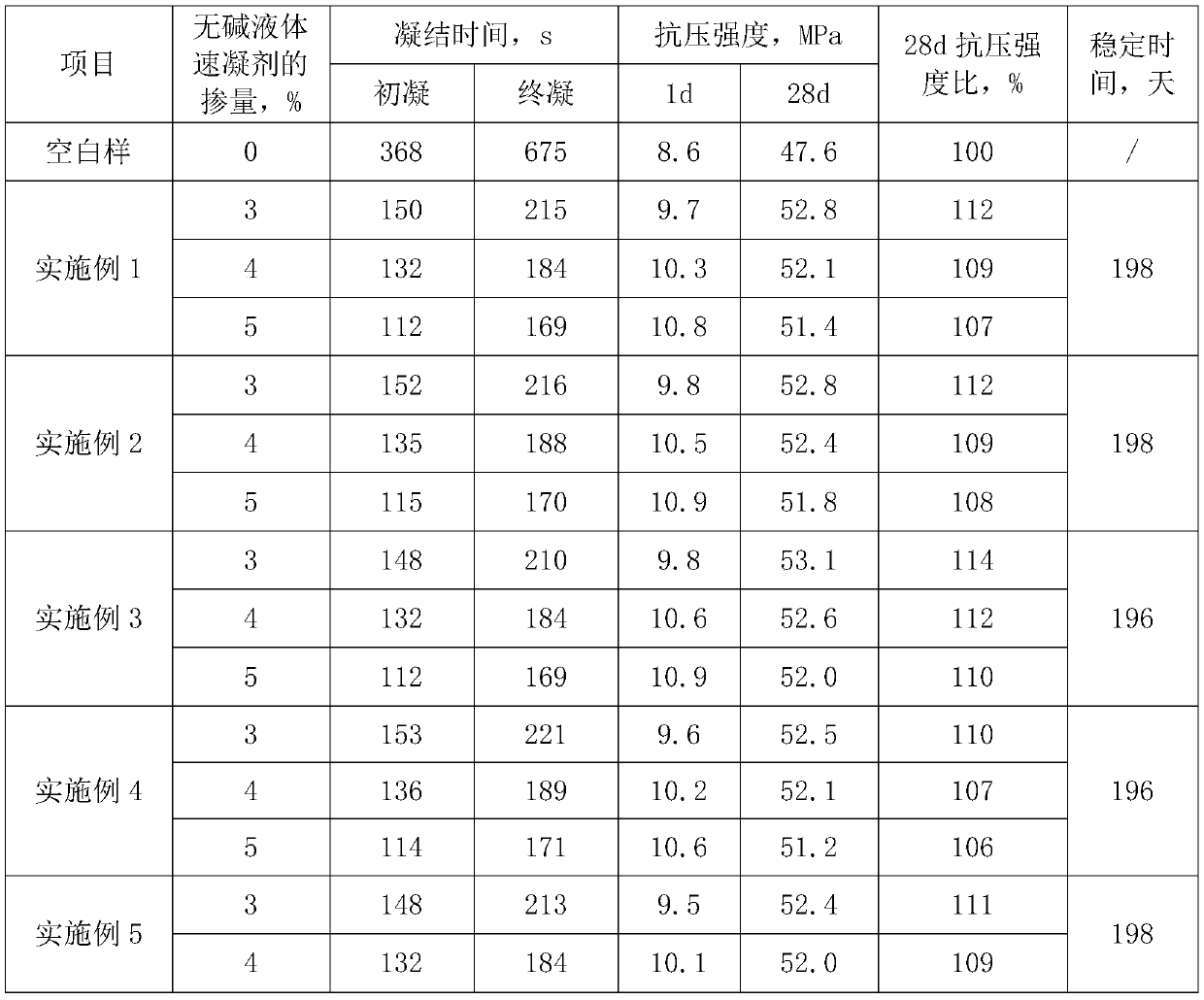

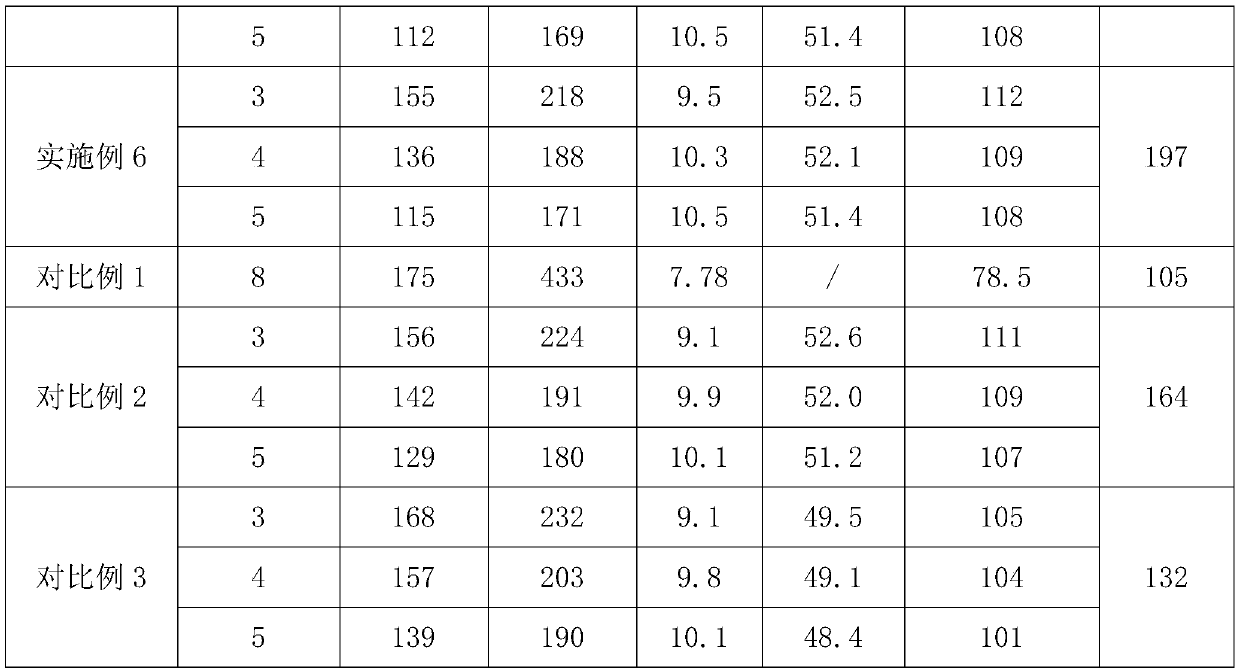

Examples

preparation example 1

[0031] Preparation example 1: ①Dissolve anhydrous aluminum sulfate in water, heat it to 40°C, and prepare an aluminum sulfate solution with 20wt% aluminum sulfate; add NH2 dropwise to the 20wt% aluminum sulfate solution 3 10wt% ammonia water, keep stirring, adjust the pH to 6.5-6.7 as the titration end point, and obtain an aluminum hydroxide colloidal solution; after washing the prepared aluminum hydroxide colloidal solution with distilled water, place it at a temperature of 70°C, Drying for 6 hours to obtain dried aluminum hydroxide colloid; grinding the dried aluminum hydroxide colloid to obtain aluminum hydroxide colloid powder with a fineness of 100-400 mesh;

[0032] ② In parts by weight, take 30kg of the 20wt% aluminum sulfate solution in step ①, heat it up to 70°C, add 3kg of basic aluminum lactate to it, stir evenly, add 10kg of aluminum hydroxide colloidal powder, keep warm and stir for 1h After that, polyaluminum sulfate is obtained.

preparation example 2

[0033] Preparation example 2: ①Dissolve anhydrous aluminum sulfate in water, heat it to 45°C, and prepare an aluminum sulfate solution with 20wt% aluminum sulfate; add NH2 dropwise to the 20wt% aluminum sulfate solution 3 10wt% ammonia water, keep stirring, adjust the pH to 6.5-6.7 as the titration end point, and obtain an aluminum hydroxide colloidal solution; after washing the prepared aluminum hydroxide colloidal solution with distilled water, place it at a temperature of 75°C, Dry for 7 hours to obtain dry aluminum hydroxide colloid; grind the dried aluminum hydroxide colloid to obtain aluminum hydroxide colloid powder with a fineness of 100-400 mesh;

[0034] ② In parts by weight, take 30kg of the 20wt% aluminum sulfate solution in step ①, heat it up to 75°C, add 4kg of basic aluminum lactate to it, stir evenly and add 15kg of aluminum hydroxide colloidal powder, keep stirring for 1.5 After h, polyaluminum sulfate is obtained.

preparation example 3

[0035] Preparation example 3: ①Dissolve anhydrous aluminum sulfate in water, heat it to 50°C, and prepare an aluminum sulfate solution with 20wt% aluminum sulfate; add NH 3Ammonia water of 10wt%, heat preservation and stirring, adjust the pH to 6.5-6.7 as the titration end point to obtain an aluminum hydroxide colloidal solution; after washing the prepared aluminum hydroxide colloidal solution with distilled water, place it at a temperature of 80°C, Drying for 8 hours to obtain dried aluminum hydroxide colloid; grinding the dried aluminum hydroxide colloid to obtain aluminum hydroxide colloid powder with a fineness of 100-400 mesh;

[0036] ②In parts by weight, take 30kg of the 20wt% aluminum sulfate solution in step ①, heat it up to 80°C, add 5kg of basic aluminum lactate to it, stir evenly, add 20kg of aluminum hydroxide colloidal powder, keep stirring for 2h After that, polyaluminum sulfate is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com