Oil-based drilling waste supercritical treatment system

A treatment system, oil-based drilling technology, applied in the direction of mining wastewater treatment, sludge treatment, special treatment targets, etc., can solve the problems of mud aging, unfriendly environment, inevitable secondary pollution of air pollutants, etc., to achieve low viscosity , the effect of high diffusion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

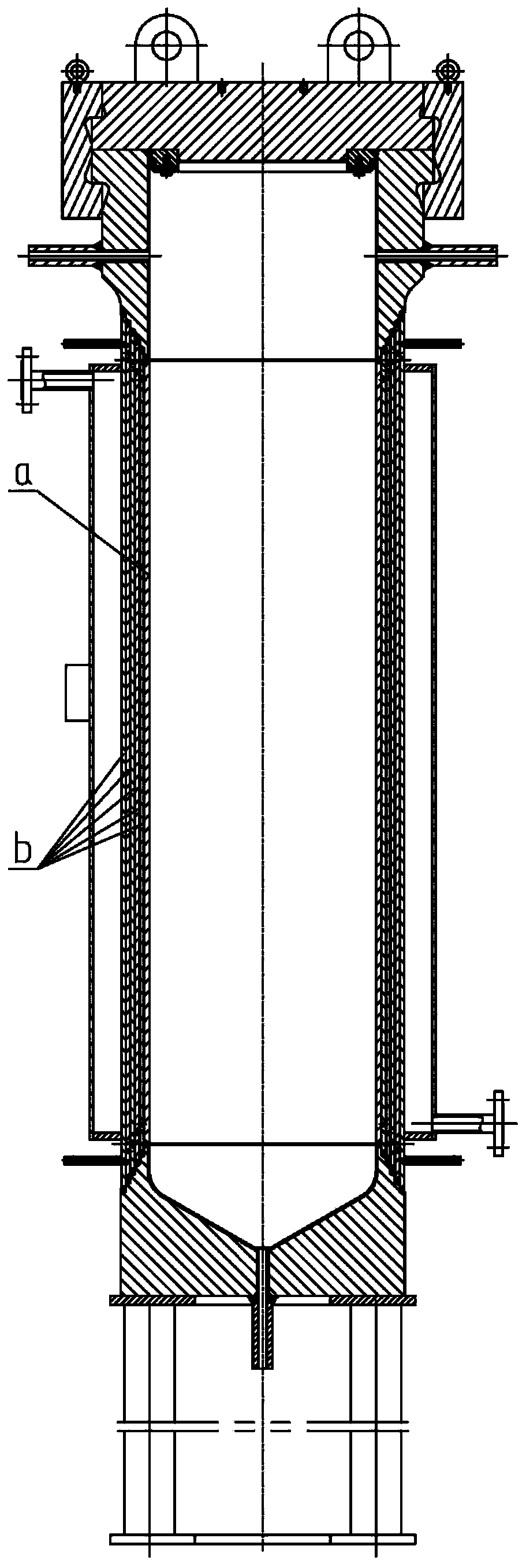

[0076] see figure 1 , this embodiment is composed of an extraction unit, a separation unit, an extraction agent recovery unit, an extraction agent filling unit, an energy recovery balance unit, and a control unit.

[0077] The extraction unit is divided into two paths, one path is the waste feed pipeline II, the oil-based drilling waste is stored in the waste storage tank 22, and a heating coil is arranged in the waste storage tank 22, and the thermal circulation fluid used for heating in the coil is Provided by the energy recovery balance unit 18, the waste is heated to the set temperature by the heating coil before being added to the extraction kettle, and then fed into the extraction kettle I5a or the extraction kettle II5b by the screw pump 23 respectively (see figure 2 ), the pressure in the extraction kettle is low when feeding, which does not af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com