A kind of Ganoderma lucidum polysaccharide granule and its preparation method and application

A technology of Ganoderma lucidum polysaccharides and granules, which is applied in applications, polysaccharide/gum-containing food ingredients, pharmaceutical formulations, etc., can solve the problems of unfavorable formation of Ganoderma polysaccharide storage preparations, poor hygroscopicity and fluidity of granules, and unfavorable storage preparations. Good fluidity and dispersibility, high yield and drug loading, and weak hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: Preparation of Ganoderma lucidum polysaccharide

[0028] Ganoderma lucidum is subjected to water extraction or water extraction and alcohol precipitation (water temperature 100°C, time 90min, solid-liquid ratio 1:20, extraction twice) and then spray drying or belt drying (spray conditions: inlet air temperature 120°C, atomization pressure 0.2 MPa, outlet temperature 75-80°C), and crushed and passed through a 60-100 mesh sieve to obtain Ganoderma lucidum polysaccharide.

Embodiment 2

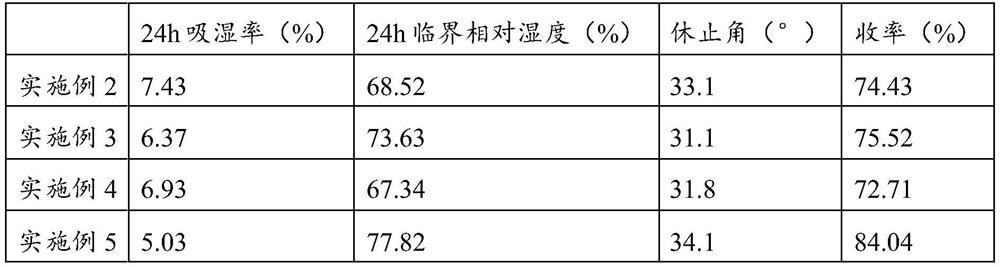

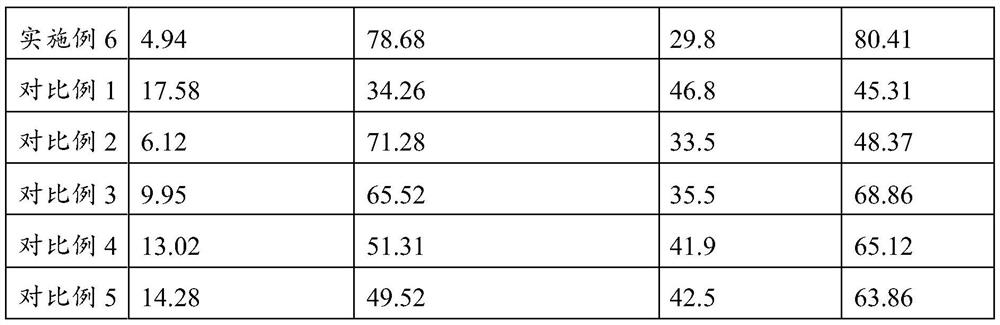

[0029] Embodiment 2: Preparation of Ganoderma lucidum polysaccharide particles of the present invention

[0030] Take 20 parts of Ganoderma lucidum polysaccharide and 20 parts of sodium starch phosphate, mix them evenly, and put them into a fluidized bed granulator. The temperature is 60°C, the material temperature is 50°C, the liquid supply speed is 10rpm, the fan frequency is 15Hz, 30 minutes after the end of liquid supply, 28 parts of 2% gum arabic aqueous solution is added, and the coating conditions are set as: inlet air temperature The temperature is 50°C, the material temperature is 45°C, the liquid supply speed is 8rpm, and the fan frequency is 15Hz. Carry out sizing with a 20-80 mesh sieve, and the yield is 74.43%.

[0031] Determination of hygroscopicity: Weigh 1 g of the prepared particles, spread them in a weighing bottle, and accurately weigh the mass of the original sample. Place the weighing bottle open in a constant temperature and humidity chamber under the ...

Embodiment 3

[0038] Embodiment 3: Preparation of Ganoderma lucidum polysaccharide particles of the present invention

[0039] Take 10 parts of Ganoderma lucidum polysaccharide, 6 parts of chitosan hydrochloride, and 10 parts of sodium starch phosphate, and put them into a fluidized bed granulator after mixing evenly. The granulation conditions are set as follows: air inlet temperature is 60°C, material temperature is 50°C, liquid supply speed: 10rpm, fan frequency is 15Hz, 22.75 parts of 2% gum arabic aqueous solution with mass percentage concentration is added after 30 minutes after the liquid supply, and coated The conditions are set as follows: the inlet air temperature is 50°C, the material temperature is 45°C, the liquid supply speed is 8rpm, and the fan frequency is 15Hz. Carry out granulation with 20-80 mesh sieves, and the yield is 75.52%. According to the measurement method of Example 2, the moisture absorption rate in 24 hours was 6.37%, the critical relative humidity in 24 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of repose | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com