Integrated equipment for paste forming and molding of raw potato products

An all-in-one machine and product technology, applied in the field of product processing, can solve problems such as high labor intensity, low production efficiency, and affecting processing quality, and achieve the effects of rapid cleaning and finishing, improved uniformity, and increased productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but are not intended to limit the protection scope of the present invention.

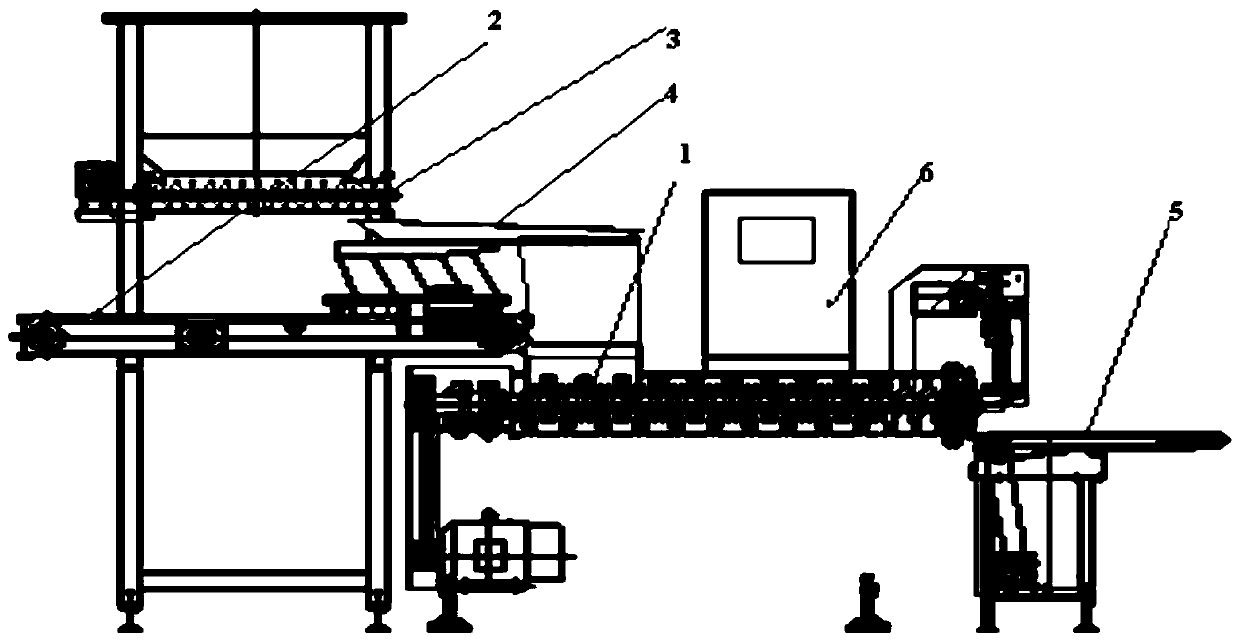

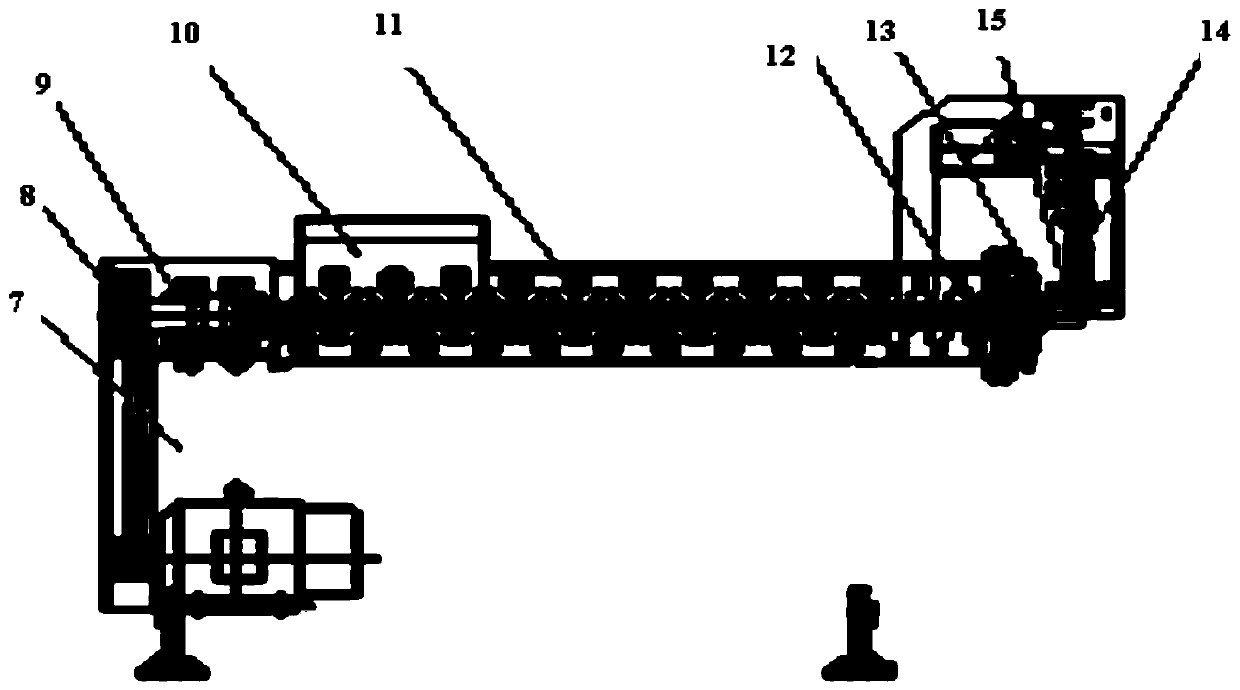

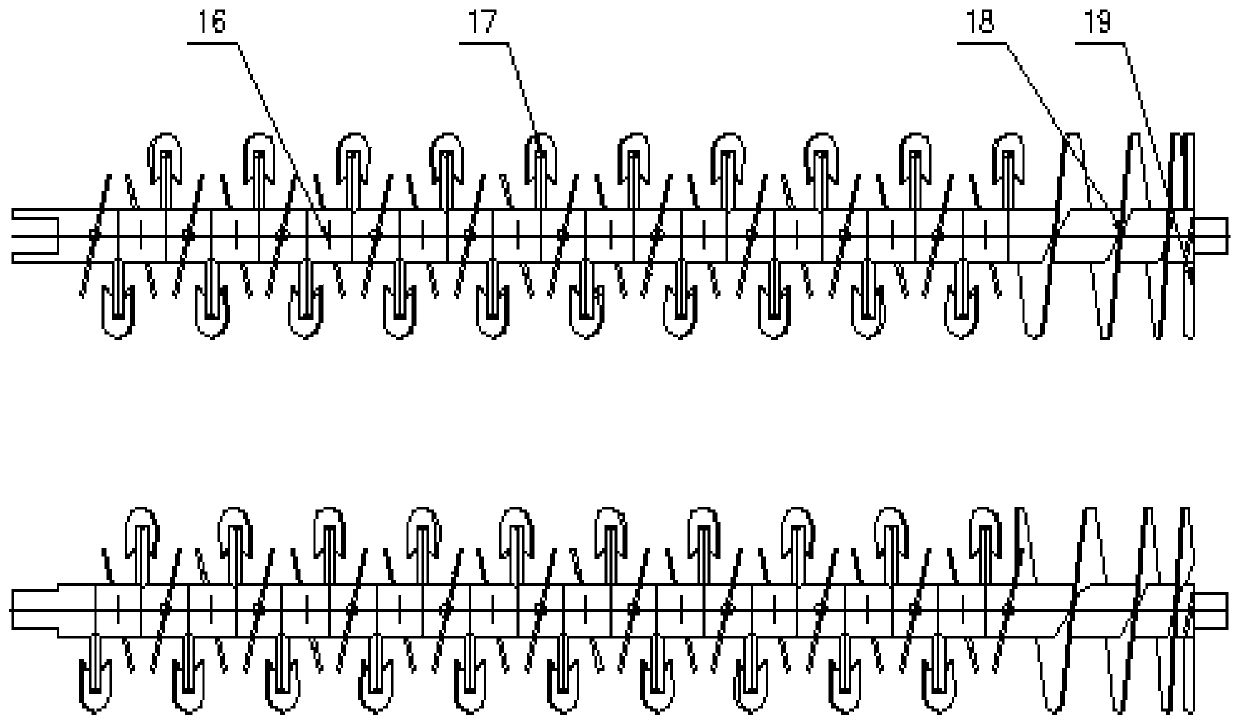

[0034] Such as figure 1 As shown, the equipment in this embodiment is composed of a mud-making and forming integrated machine host 1, a feeding belt conveyor 2, an auxiliary material conveying device 3, an electromagnetic vibrating distributor 4, a discharging belt conveying device 5, and an electrical control device 6 components. Its working process is as follows: the boiled and ripened sliced potatoes are fed into the cavity of the host machine 1 of the all-in-one mud making and forming machine by the feeding belt conveyor 2, and the powdery auxiliary materials that need to be added are stored in the hopper of the auxiliary material conveying device 3 and then transported to the screen surface of the electromagnetic vibrating distributor 4; after being vibrated an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com