A wiring harness terminal

A technology for connecting terminals and wiring harnesses, applied in the field of electrical equipment, can solve the problems of insufficient wiring efficiency, low installation practicability, wire damage, etc., and achieve the effect of improving wiring efficiency and installation practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

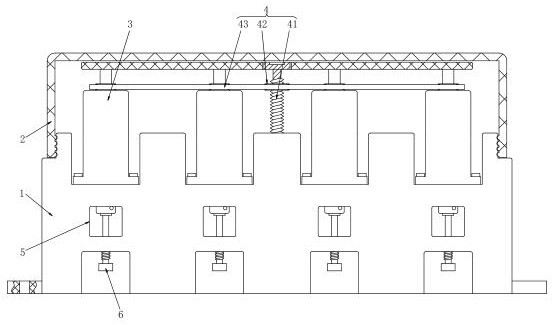

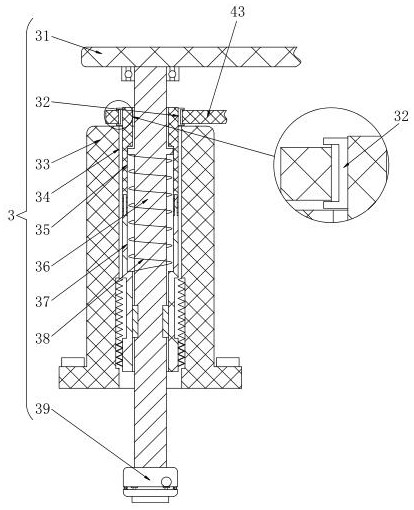

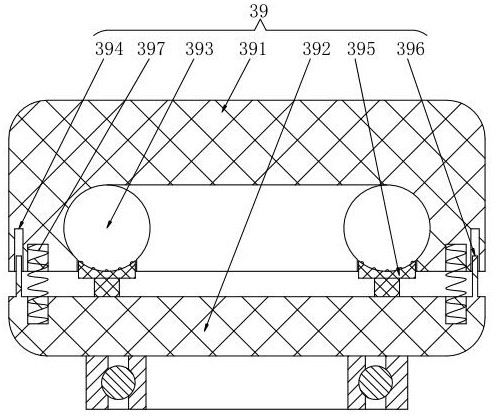

[0024] As shown in 1-5, a wire harness terminal includes a wire base 1, a protective cover 2, a screw assembly 3, a drive assembly 4, a wiring hole 5 and a threaded push rod 6, and the top ends of the wire base 1 are equally spaced. There is an installation slot, the screw assembly 3 is fixed inside the installation slot by bolts, the drive assembly 4 is arranged at the top center of the terminal block 1, and the protective cover 2 is connected to the upper end of the terminal block 1 by a buckle, and the screw assembly 3 and The driving components 4 are all locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com