System-in-package thermal reliability comprehensive optimization design method

A system-in-package, optimized design technology, used in computing, special data processing applications, instruments, etc., to solve problems such as cracks, less reliability of micro-bumps, and reliability of warped micro-bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

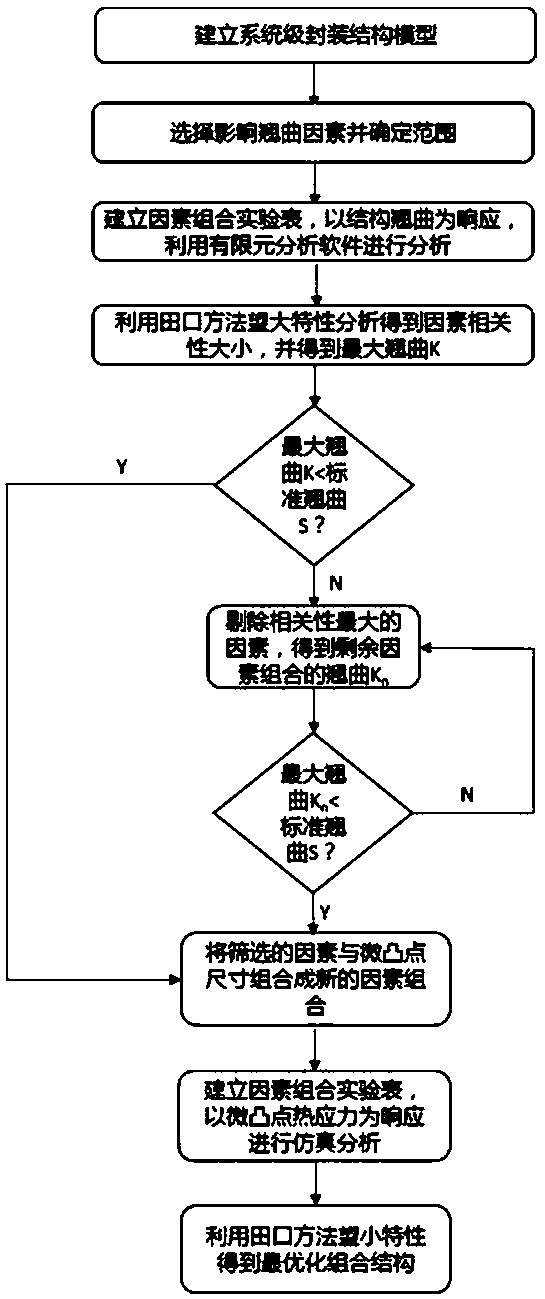

[0026] The comprehensive optimization design method of the system-in-package thermal reliability of the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0027] It is realized through the following technical solutions: establishing a system-level package structure model, including a substrate 1, a redistribution layer 3, micro bumps 2, a bare chip 5 and an epoxy molding material 4.

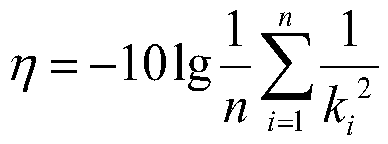

[0028] Screen the relevant factors A, B, C, D, E that affect structural warpage, and consider the actual process to determine the level of factors. Among them, A represents the thickness of the substrate 1, B represents the thickness of the overmolding layer 6, C represents the thickness of the redistribution layer 3, D represents the thickness of the epoxy molding material 4, and E represents the thickness of the 5 layers of the bare chip; The curve is the response condition, and the test is simulated by using finite element analysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com