Dimensional Measurement Method for Matching Relationship of Automobile Outer Covers

A technology of outer cover and matching relationship, which is applied in the field of precision measurement, can solve problems that affect the accuracy of measurement results, measurement data deviation, easy deformation, etc., and achieve the effects of saving online debugging time, improving measurement accuracy, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention is described in detail below in conjunction with accompanying drawing:

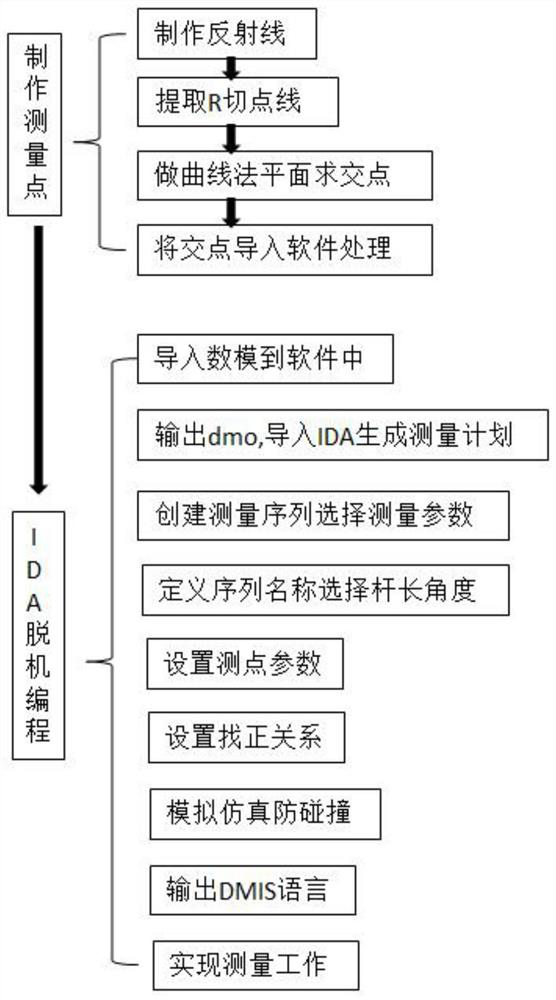

[0064] A method for measuring the size of the matching relationship of an automobile outer cover, comprising the following steps:

[0065] 1. Making measurement points

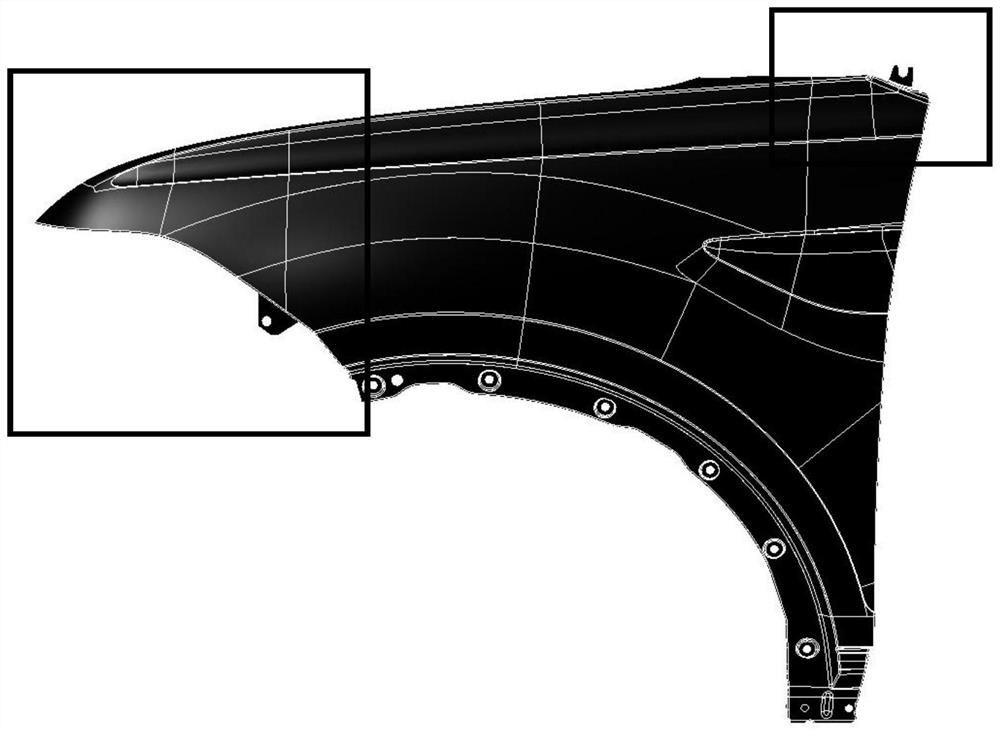

[0066] First, select the single-chip digital model of the product in the CATIA software, and then use it to lay out the measurement points. The measurement points need to be arranged on a single digital model. If it is a solid digital model, the surface should be truncated after extracting the surface, otherwise the required curve cannot be extracted.

[0067] The layout principle of the measurement points: distribute a column of measurement points every 50 mm around the digital model outline of the fender single-piece product (some key areas are properly encrypted, such as the eagle beak area matching the headlights, the fist area matching the A-pillar and On both sides of the ridge line) three points are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com