Drying system and method using greenhouse combining industrial waste heat with solar energy

A solar greenhouse, industrial waste heat technology, applied in heating systems, hot water central heating systems, heating to dry solid materials, etc. Instability, increase drying rate, enhance the effect of heat and mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

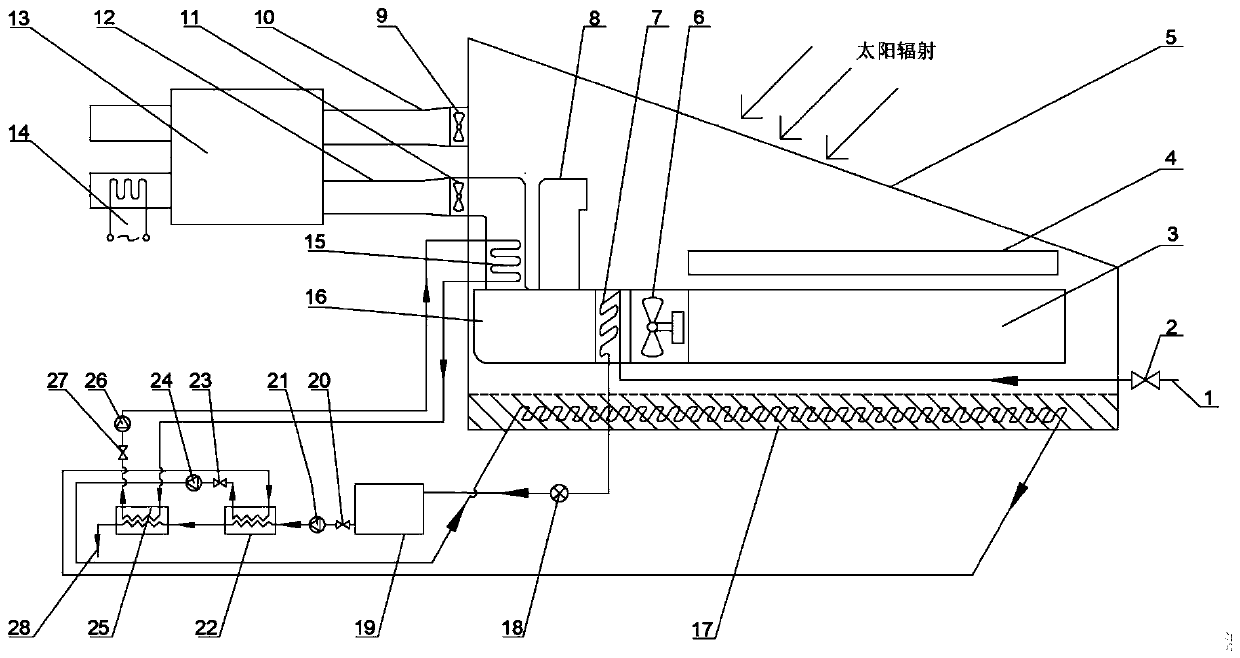

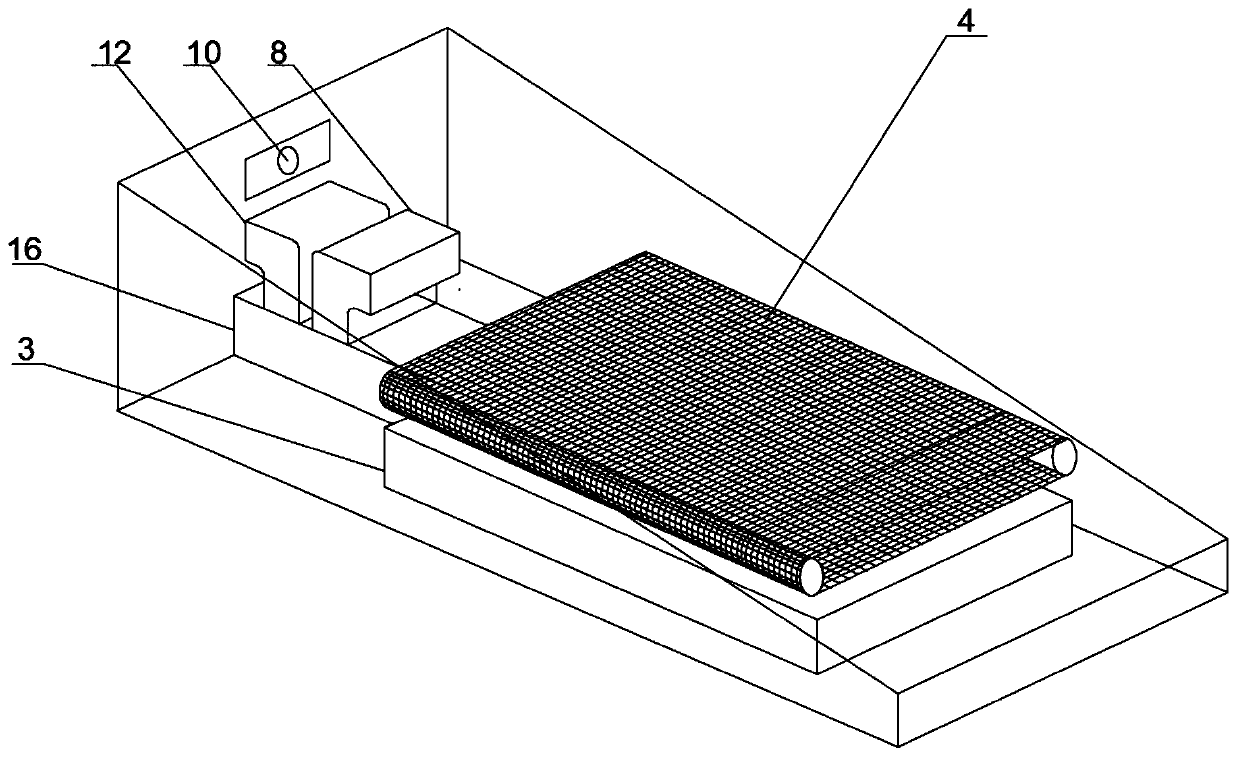

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

[0032] Such as figure 1 Shown is an industrial waste heat composite solar greenhouse drying system. The greenhouse is equipped with a ventilated mesh conveyor belt 4; The included angle of the horizontal plane is 30° (the angle is set according to the geographical location of our country, and adjusted according to the use environment in order to maximize the direct sunlight as the goal), and solar energy is used to increase the internal temperature of the greenhouse; the ventilation net A bellows 3 is arranged below the perforated conveyor belt 4, and the air outlet of the bellows 3 faces the air-permeable mesh conveyor belt 4; a floor heating pipe 17 is arranged under the ground of the greenhouse; The air outlet communicates with the air inlet of the bellows 3 .

[0033]The return air inlet of described air supply bin 16 is communicated with the air outlet of return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com