Pressure type water flushing system and toilet pan

A pressure type, toilet technology, applied in the field of sanitary ware, can solve the problems of limited ceramic space, squeezed installation space, inconvenient installation process, etc., and achieves the effects of simple structure, energy saving and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

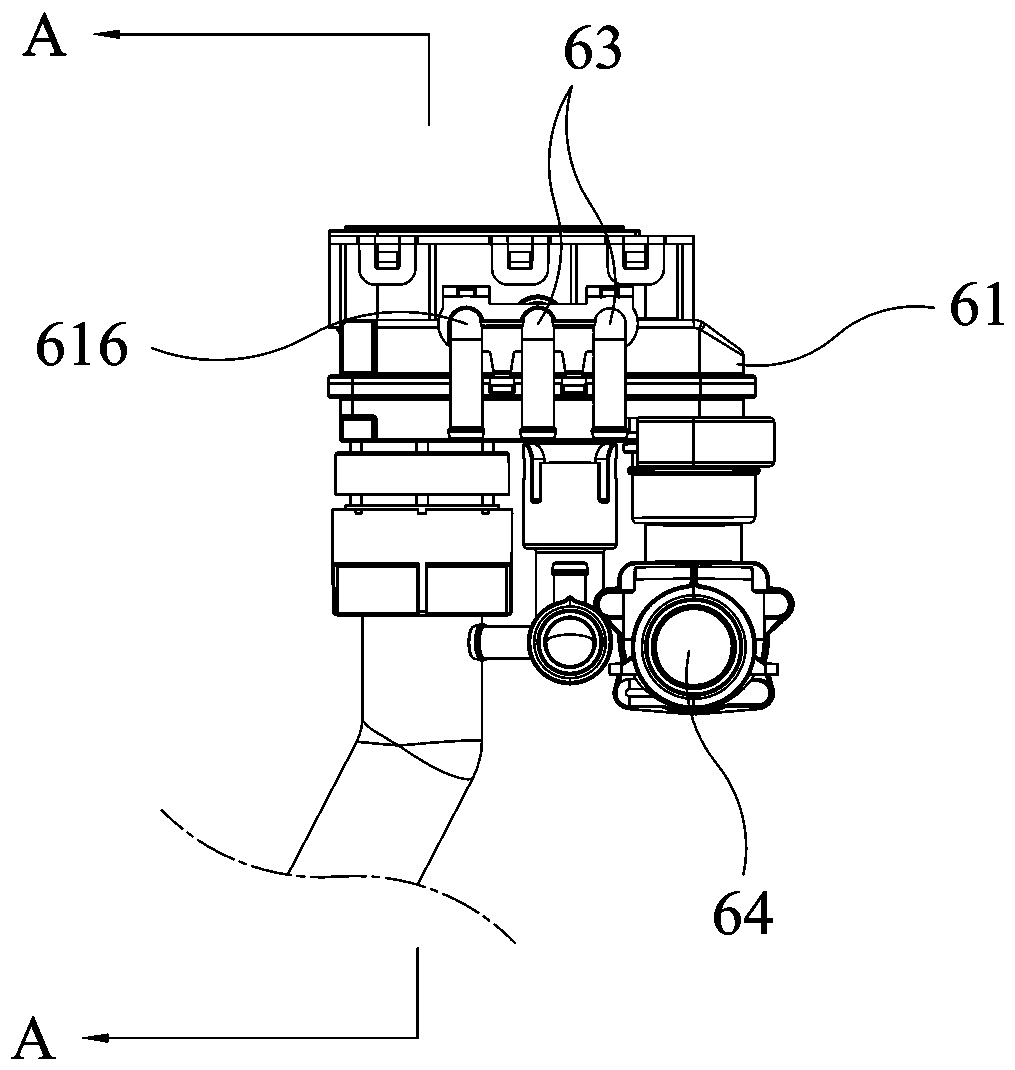

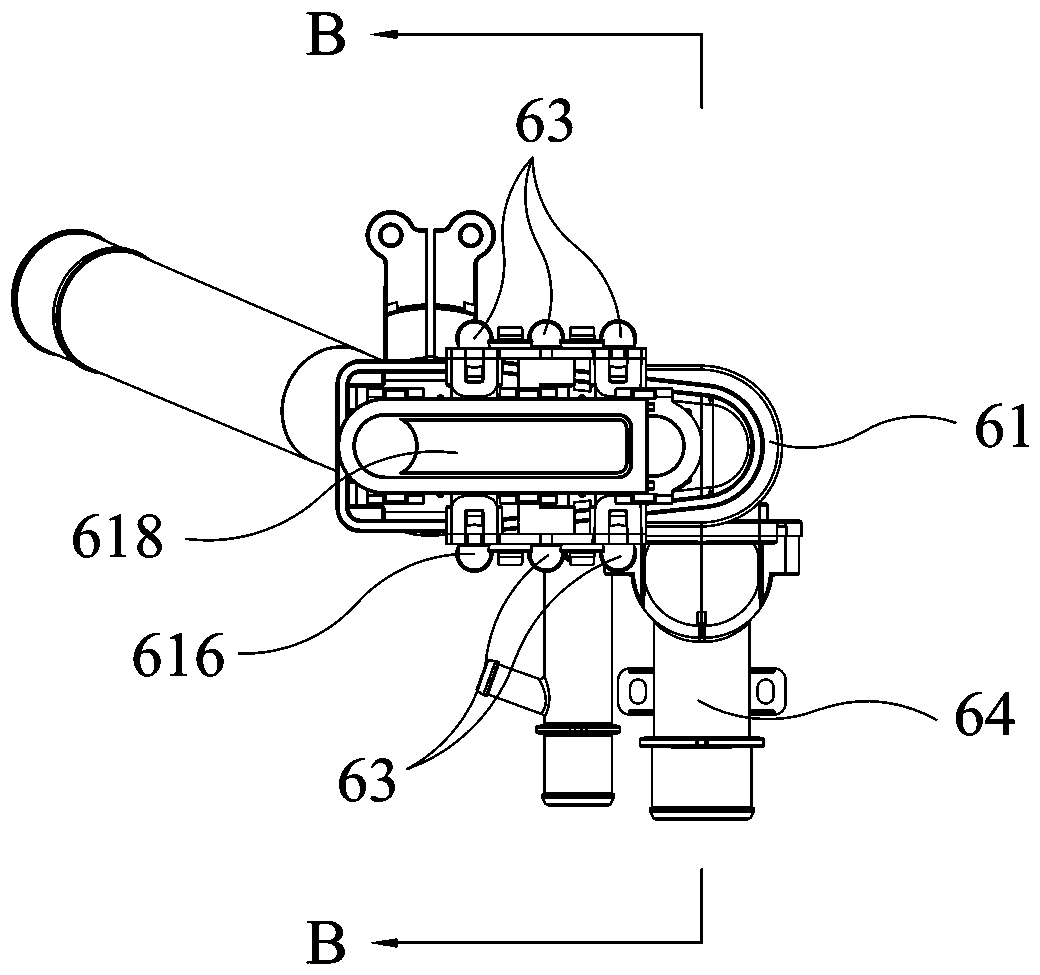

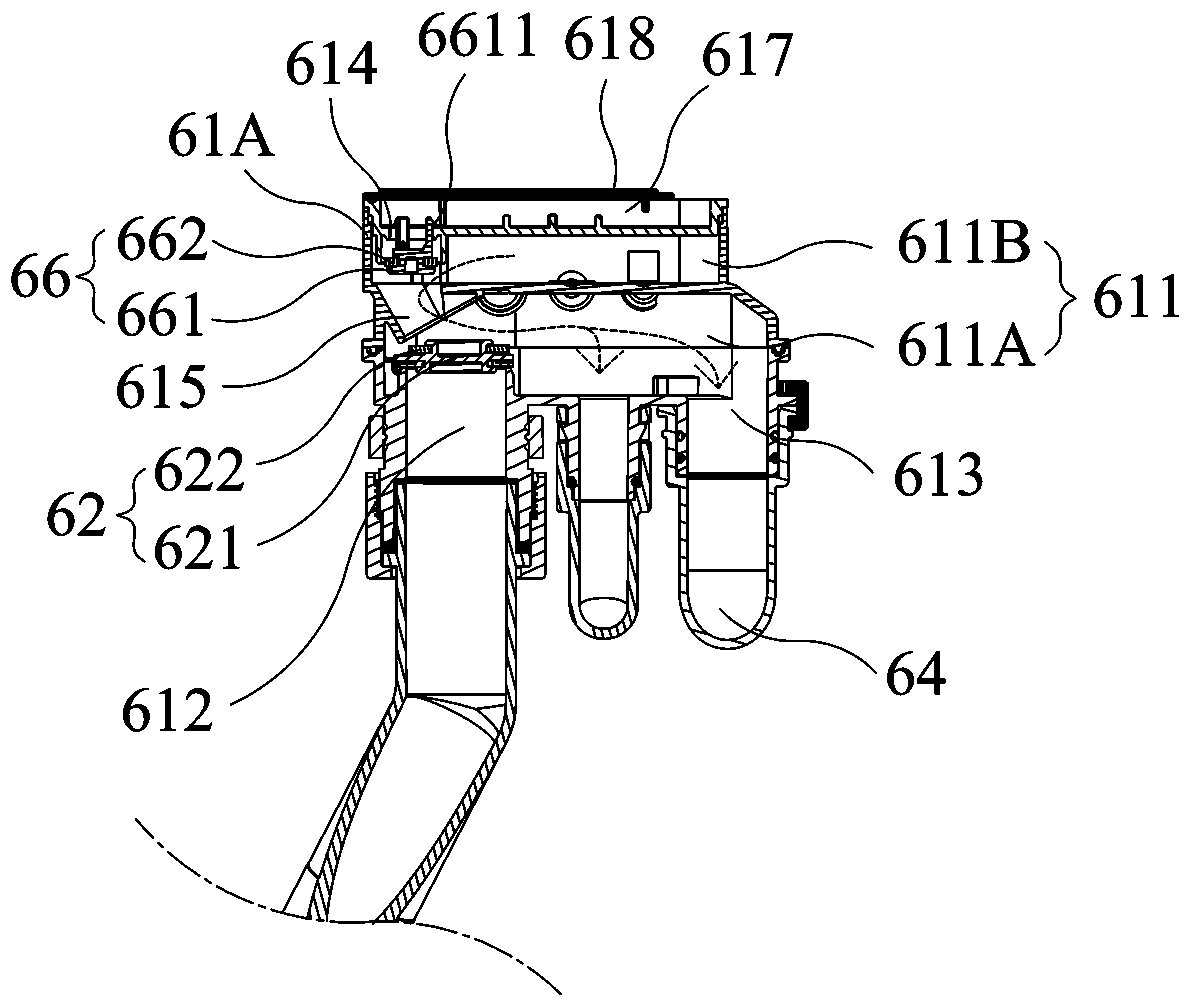

[0046] refer to Figure 1 to Figure 25 As shown, the present invention is a pressure type flushing system and toilet. The above-mentioned pressure flushing system includes a first container 11 and a second container 12, and a connecting member 13 communicating with the first container 11 and the second container 12; the first container 11 is formed with a first water inlet 111 and a water outlet 112, water flows into the first container 11 from the first water inlet 111, and the water in the second container 12 flows in from the first container 11 through the connecting piece 13; the gas in the first container 11 and the second container 12 is gradually compressed during the water intake process Stored in the upper part of the second container 12 , the compressed gas pushes the water in the first container 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com