Fertilizer special for improving physical and chemical properties of tobacco planting soil

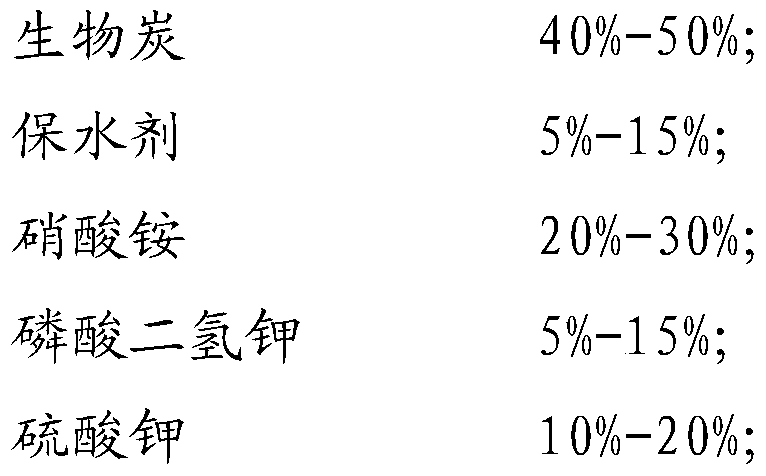

A special fertilizer technology with physical and chemical properties, applied in the direction of alkaline orthophosphate fertilizer, fertilizer mixture, ammonium orthophosphate fertilizer, etc., can solve the problems of soil carbon storage capacity decline, poor soil physical and chemical properties, soil compaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of biochar comprises the following steps:

[0026] 1) Place the peanut shells in the carbonization furnace, and control the temperature of the carbonization furnace to rise at a constant speed of 16°C / min;

[0027] 2) When the furnace temperature of the carbonization furnace reaches 450±30°C, stop heating and keep it warm for 30 minutes;

[0028] 3) Quickly cool down to room temperature to prepare biochar.

[0029] Rapid cooling refers to the cooling rate ≥ 10°C / min, usually 10°C / min, the reason for rapid cooling is that it can increase the porosity of biochar and increase the specific surface area. When , potassium dihydrogen phosphate and potassium sulfate are compounded, some other components will enter the pores of biochar, which will improve the slow-release effect and prolong the life of the fertilizer.

[0030] The basic physical and chemical indicators of biochar are pH 8.45-8.55, total carbon content 48.30%-48.64%, total nitrogen conten...

Embodiment 1

[0038] Example 1 (T1): biochar: 40%, water retaining agent: 0%, peanut shell (not carbonized): 10%, ammonium nitrate: 25%, potassium dihydrogen phosphate: 10%, potassium sulfate: 15%.

Embodiment 2

[0039] Example 2 (T2): biochar: 0%, water retaining agent: 10%, peanut shell (not carbonized): 40%, ammonium nitrate: 25%, potassium dihydrogen phosphate: 10%, potassium sulfate: 15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com