Artificial porous volcanic rock plate and preparation method thereof

A technology of porous volcanic rock and slate, applied in the direction of ceramic products, other household utensils, applications, etc., can solve the problems of difficult to produce large size, complicated process, low efficiency, etc., achieve high production efficiency, wide range of sources, and solve mechanical properties. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

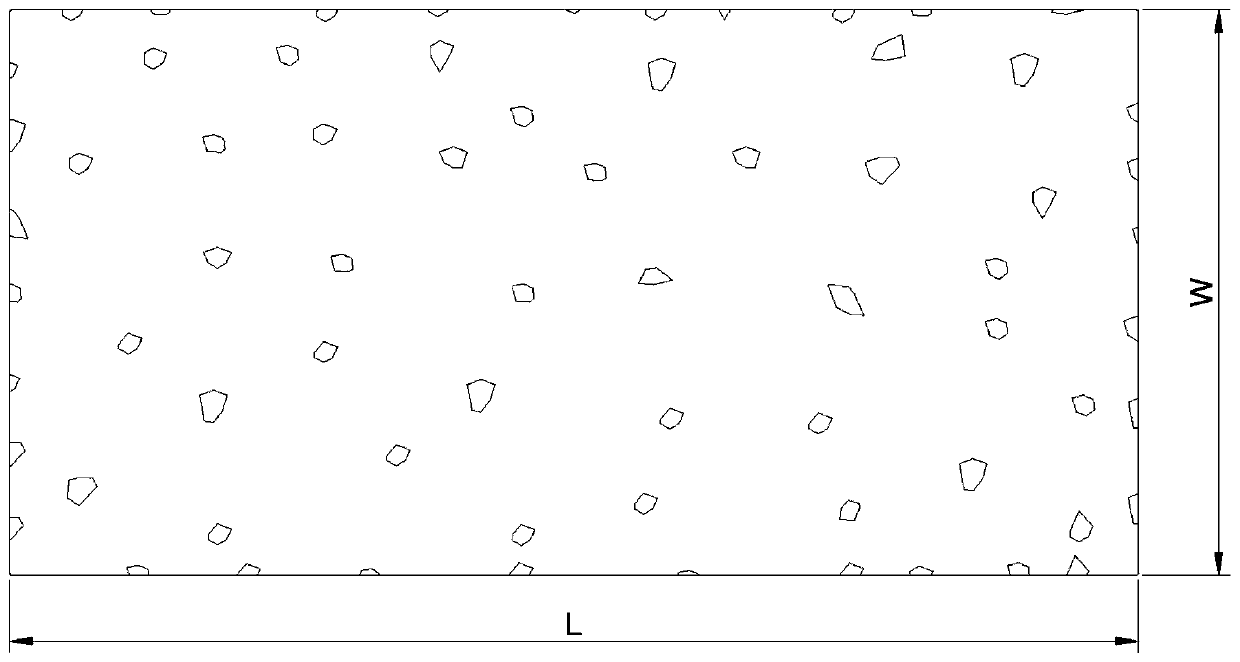

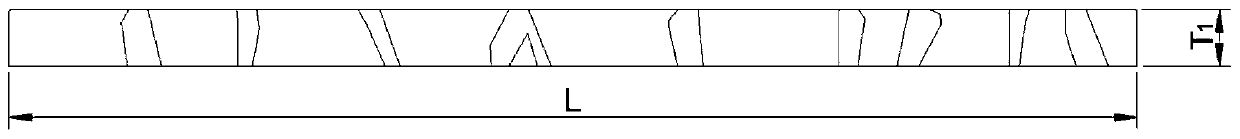

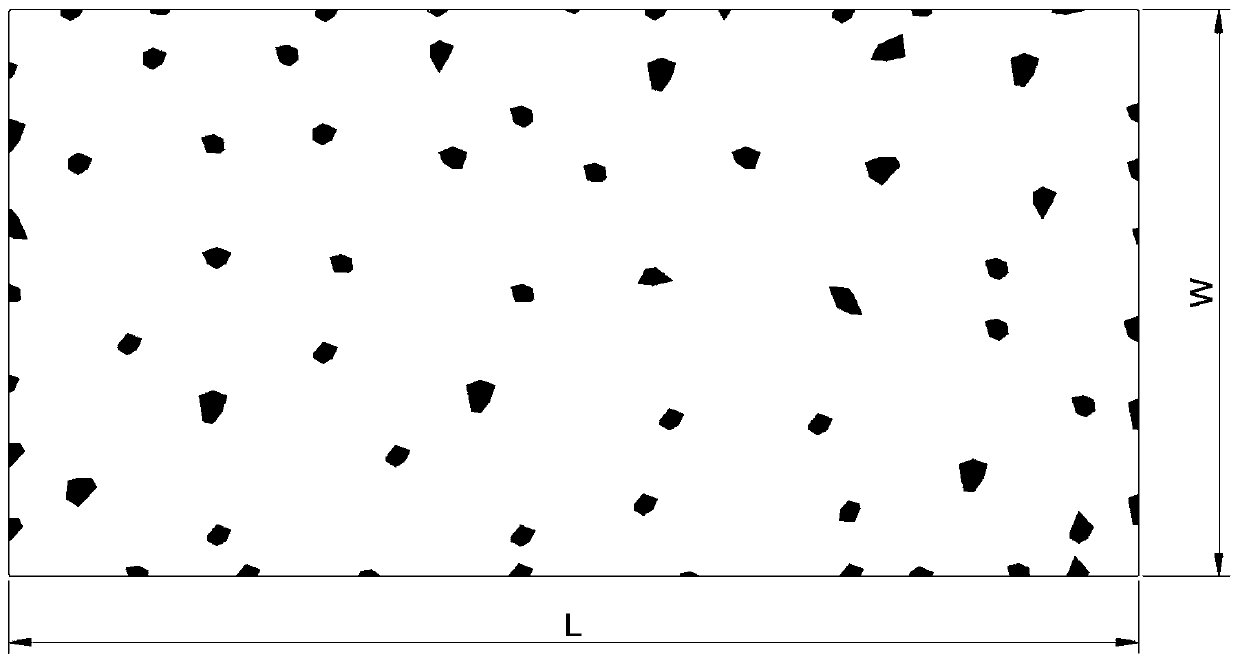

Image

Examples

Embodiment 1

[0063] A fully transparent artificial porous volcanic rock slab, the thickness of the slate is 20mm, including the following components by weight:

[0064] 600 parts of inorganic active powder with an average particle size of 5-40 μm;

[0065] 900 parts of sand with a particle size not greater than 4.75mm;

[0066] 36 pieces of ice cubes with a particle size of 20mm;

[0067] 14 parts of high-performance admixture;

[0068] 5 parts of pigment powder;

[0069] 0.01 part of retarder;

[0070] 10 parts of water repellent;

[0071] The ratio of water to glue is 0.2.

[0072] The inorganic active powder is mainly mixed with white silica powder (one or more active powders in white silica powder, mineral powder, glass microspheres, and zeolite powder can be added) with cement with a strength grade above 42.5; The sand is quartz sand (can be one or more combinations of quartz sand, river sand, machine-made sand); the high-performance additive is polycarboxylate water reducer (ca...

Embodiment 2

[0081] In this embodiment, except that the formula of the artificial porous volcanic rock plate is different, other conditions are the same as in Embodiment 1. The artificial porous volcanic rock slab includes the following components in parts by weight:

[0082] 920 parts of inorganic active powder with an average particle size of 5-40 μm;

[0083] 1200 parts of sand with a particle size not greater than 4.75mm;

[0084] 90 pieces of ice cubes with a particle size of 20mm;

[0085] 20 parts of high performance admixture;

[0086] 10 parts of pigment powder;

[0087] 0.05 parts of retarder;

[0088] 20 parts of water repellent;

[0089] The ratio of water to glue is 0.25.

Embodiment 3

[0091] In this embodiment, except that the formula of the artificial porous volcanic rock plate is different, other conditions are the same as in Embodiment 1. The artificial porous volcanic rock slab includes the following components in parts by weight:

[0092] 680 parts of inorganic active powder with an average particle size of 5-40 μm;

[0093] 975 parts of sand with a particle size not greater than 4.75mm;

[0094] 50 pieces of ice cubes with a particle size of 20mm;

[0095] 16.5 parts of high-performance admixture;

[0096] 6 parts of pigment powder;

[0097] 0.02 parts of retarder;

[0098] 12.5 parts of water repellent;

[0099] The ratio of water to glue is 0.21.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com