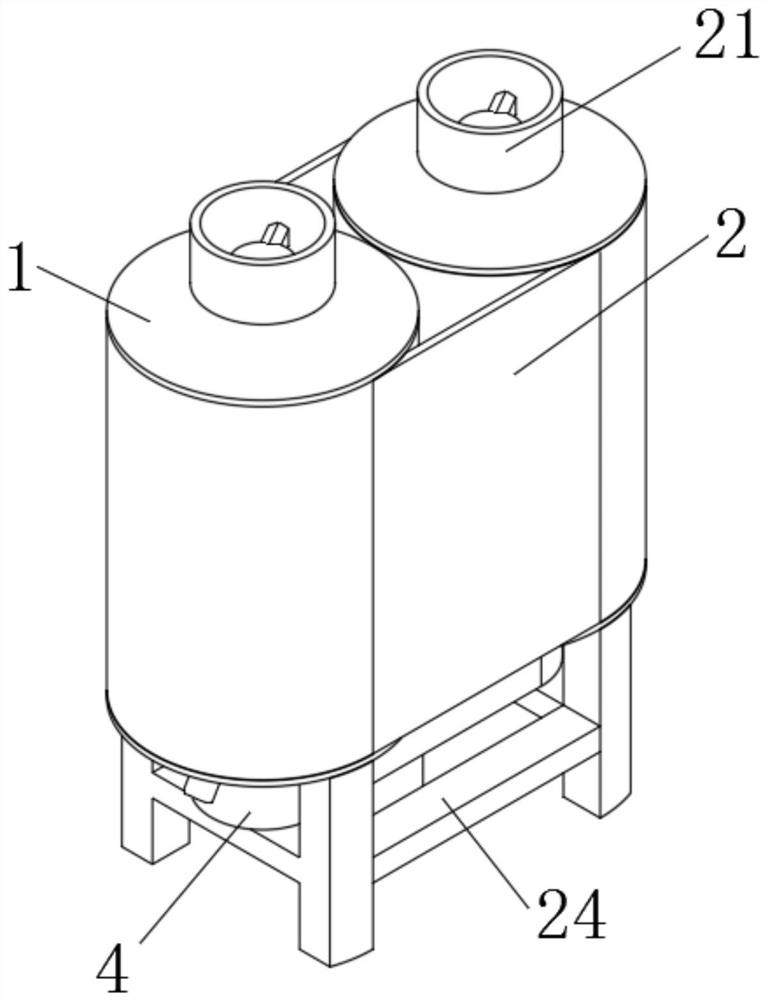

A dry-mixed masonry mortar preparation equipment

A technology of masonry mortar and dry mixing, which is applied in clay preparation devices, chemical instruments and methods, cement mixing devices, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

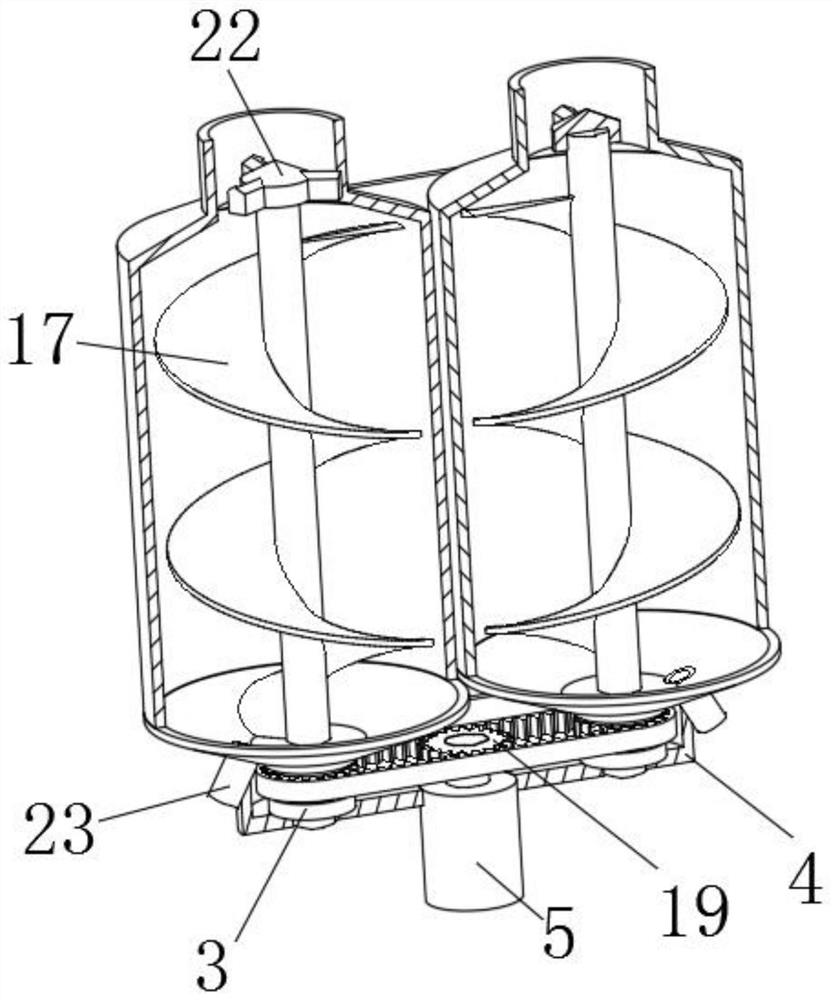

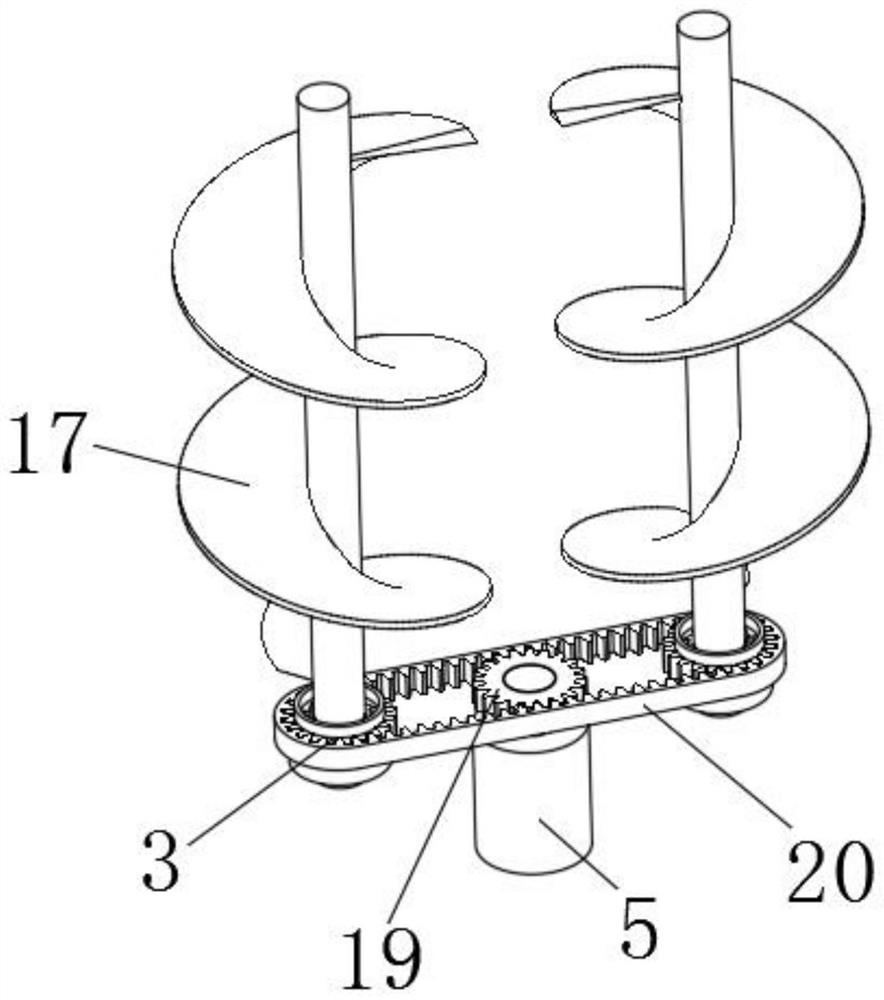

specific Embodiment approach

[0031] The specific embodiment: the main unidirectionality of the one-way transmission device 3 is completed by the ratchet 10 and the ratchet 8. When the rotation direction of the ratchet 10 is from the arc surface side of the ratchet 8 to the plane side, the ratchet The long slope of the tooth groove of 10 is slidingly connected with the top of the ratchet 8, because the sliding connection occurs, so that the driven wheel 7 will not be driven, and when the first gear 6 moves in the opposite direction, the short slope of the tooth groove of the ratchet 10 will not be driven. It will be against the ratchet 8, and the space between the ratchet 8 and the ratchet 10 is too small to make the ratchet 8 rotate, so that the ratchet 10 drives the driven wheel 7 to rotate through the ratchet 8, and the ratchet 10 and the ratchet 8 When relative sliding occurs, the tooth tip of the ratchet wheel 10 will press the ratchet 8 down. When there is no return mechanism, the ratchet 8 cannot be ...

Embodiment 1

[0037] A kind of dry-mixed masonry mortar, according to the mass percentage, the specific position is 14% of cement, 8% of pulverized coal powder, 28% of 3-5mm coarse sand, 13% of 1.6-3mm medium sand, 14% of 0.8-1.6mm medium sand, 14% of fine sand below 0.8mm, 0.1% of wood calcium powder and 0.02% of cellulose ether.

Embodiment 2

[0039] The technical features of embodiment two are basically the same as embodiment one, the only difference is that a dry-mixed masonry mortar is 18% of cement, 12% of pulverized coal powder, 31% of 3-5mm coarse sand, 16% of 1.6-3mm medium sand, 16% of 0.8-1.6mm medium sand, 16% of fine sand below 0.8mm, 0.05% of wood calcium powder and 0.01% of cellulose ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com