Automobile intercooler flat pipe inner fin inserting and flat pipe leveling integrated equipment

A technology of inner fins and flat tubes is applied in the field of integrated equipment of inner fin insertion and flat tube leveling of flat tubes of automobile intercoolers, which can solve the problems of large production land, poor control and high cost, and save work. site, reduced labor costs, and a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

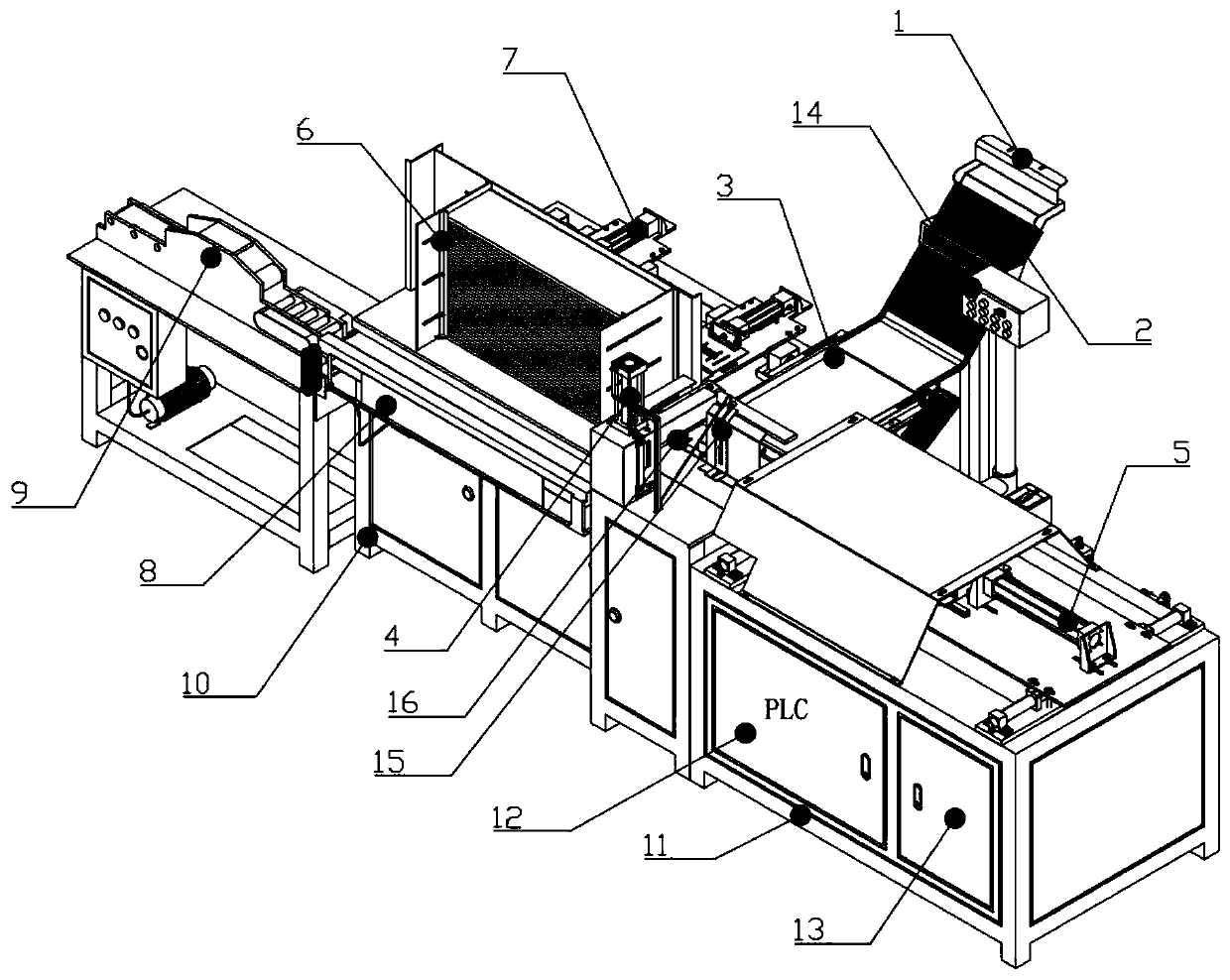

[0033] like figure 1 As shown, an integrated equipment for inserting fins in flat tubes of an automobile intercooler and leveling flat tubes, the equipment includes a frame, a fin transfer module, a fin pre-compression unit 4, a fin compression unit 16, a flat tube Storage unit 6, fin propulsion unit 5, flat tube pushing unit 7, flat tube correction and rolling unit 9, flat tube delivery unit 8, PLC programmable controller 12, electrical operation unit 14, pneumatic components and pipeline unit 13 .

[0034] The frame includes a storage tube rack unit 10 located at the middle of the frame for setting the flat tube push-out unit 7 and a flat tube storage unit 6, and a fin propulsion unit located at one side of the storage tube rack unit 10 5. The PLC programmable controller 12 and the pneumatic components and the fins of the pipeline unit 13 propel the rack unit 11 .

[0035] The fin transfer module includes a fin discharge control unit 1, a fin slide delivery unit 2, a fin t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com