A preparation method and application of visible light-induced self-cleaning carbon fiber membrane

A carbon fiber membrane, self-cleaning technology, applied in chemical instruments and methods, membrane, membrane technology, etc., can solve problems such as unfavorable large-scale applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

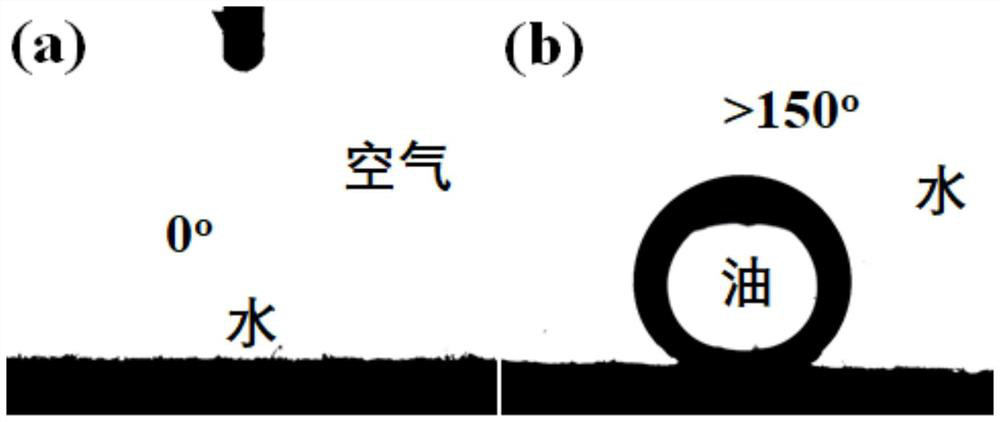

Image

Examples

Embodiment 1

[0031] Step 1. Preparation of carbon fiber membrane (CF): cut the cotton cloth into about 10cm 2 , placed in a tube furnace under a nitrogen atmosphere, the temperature was raised to 400°C at a rate of 5°C / min, and maintained for 2h. The carbonized sample was washed with ethanol and dried in an oven at 40°C for 8h to obtain a carbon fiber membrane. ;

[0032] Step 2, preparation of nickel-cobalt LDH modified carbon fiber membrane (CF / Ni-Co LDH): dissolving nickel chloride hexahydrate, cobalt chloride hexahydrate and urea in deionized water to obtain a mixed solution, wherein nickel chloride hexahydrate , The ratio of cobalt chloride hexahydrate, urea and deionized water is 2.5mmol: 5mmol: 9mmol: 50mL; pour the mixed solution into a hydrothermal kettle, then vertically put CF into the mixed solution, and conduct constant temperature water at 90°C. Thermal reaction for 9 hours; after natural cooling, take out the CF / Ni-Co LDH, wash with ethanol, and then dry at 40°C for 8 hours...

Embodiment 2

[0041] Step 1. Preparation of carbon fiber membrane (CF): cut the cotton cloth into about 10cm 2 , placed in a tube furnace under a nitrogen atmosphere, the temperature was raised to 500°C at a rate of 3°C / min, and maintained for 3h. The carbonized sample was washed with ethanol and dried in an oven at 50°C for 7h to obtain a carbon fiber membrane. ;

[0042] Step 2, preparation of nickel-cobalt LDH modified carbon fiber membrane (CF / Ni-Co LDH): dissolving nickel chloride hexahydrate, cobalt chloride hexahydrate and urea in deionized water to obtain a mixed solution, wherein nickel chloride hexahydrate , The ratio of cobalt chloride hexahydrate, urea and deionized water is 2mmol: 3mmol: 9mmol: 50mL; pour the mixed solution into a hydrothermal kettle, then put CF into the mixed solution vertically, and conduct constant temperature hydrothermal treatment at 100°C React for 10 hours; after natural cooling, take out the CF / Ni-Co LDH, wash with ethanol, and then dry at 50°C for 7 ...

Embodiment 3

[0045] Step 1. Preparation of carbon fiber membrane (CF): cut the cotton cloth into about 10cm 2 , placed in a tube furnace under a nitrogen atmosphere, the temperature was raised to 600°C at a rate of 4°C / min, and maintained for 4 hours. The carbonized sample was washed with ethanol and dried in an oven at 60°C for 6 hours to obtain a carbon fiber membrane. ;

[0046] Step 2, preparation of nickel-cobalt LDH modified carbon fiber membrane (CF / Ni-Co LDH): dissolving nickel chloride hexahydrate, cobalt chloride hexahydrate and urea in deionized water to obtain a mixed solution, wherein nickel chloride hexahydrate , The ratio of cobalt chloride hexahydrate, urea and deionized water is 0.5mmol: 1mmol: 9mmol: 50mL; pour the mixed solution into a hydrothermal kettle, then vertically put CF into the mixed solution, and conduct constant temperature water at 110°C Thermal reaction for 8 hours; after natural cooling, take out the CF / Ni-Co LDH, wash with ethanol, and then dry at 60°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com