Automatic high-pressure on-line filtering device for separation equipment and use method of automatic high-pressure on-line filtering device

A technology of separation equipment and filtration device, applied in separation methods, material separation, filtration separation, etc., can solve the problems of unreplaceable cylinders, waste of cost, and inability to reuse, to reduce sample process loss, protect from contamination, The effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Now, the present invention will be described in further detail in conjunction with the accompanying drawings and embodiments.

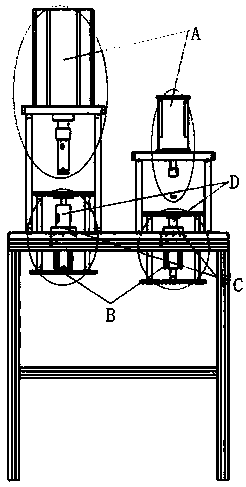

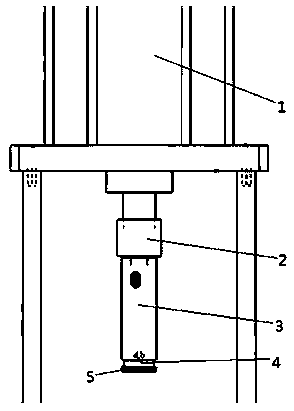

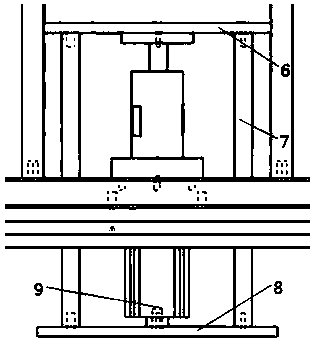

[0047] Such as figure 1 As shown, the automatic high-pressure online filter device for separation equipment of the present invention mainly includes a power module A, a preload module B, a filter cartridge C, and a filter housing D. In addition, it also includes structural components such as brackets and table tops. The structure idea of the whole device comes from the syringe.

[0048] Filter cartridge D: storage container for the sample to be filtered, with a metal filter membrane at the bottom with a pore size of 0.25 microns.

[0049] Filter housing C: The filter housing C is set at the bottom of the filter cartridge D to fix the filter cartridge D. At the same time, the bottom of the filter housing C is provided with a liquid outlet for the sample filtered from the bottom of the filter cartridge D. Separate device connections.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com