Silage maize harvester, and cutting tool and cutting cutterhead for silage maize harvester

A technology of cutting knives and cutting knives, which is applied in the field of silage harvesting tools, can solve the problems of poor wear resistance, high processing difficulty, and poor sharpness durability, so as to improve wear resistance and sharpness durability, reduce operating power consumption, reduce damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

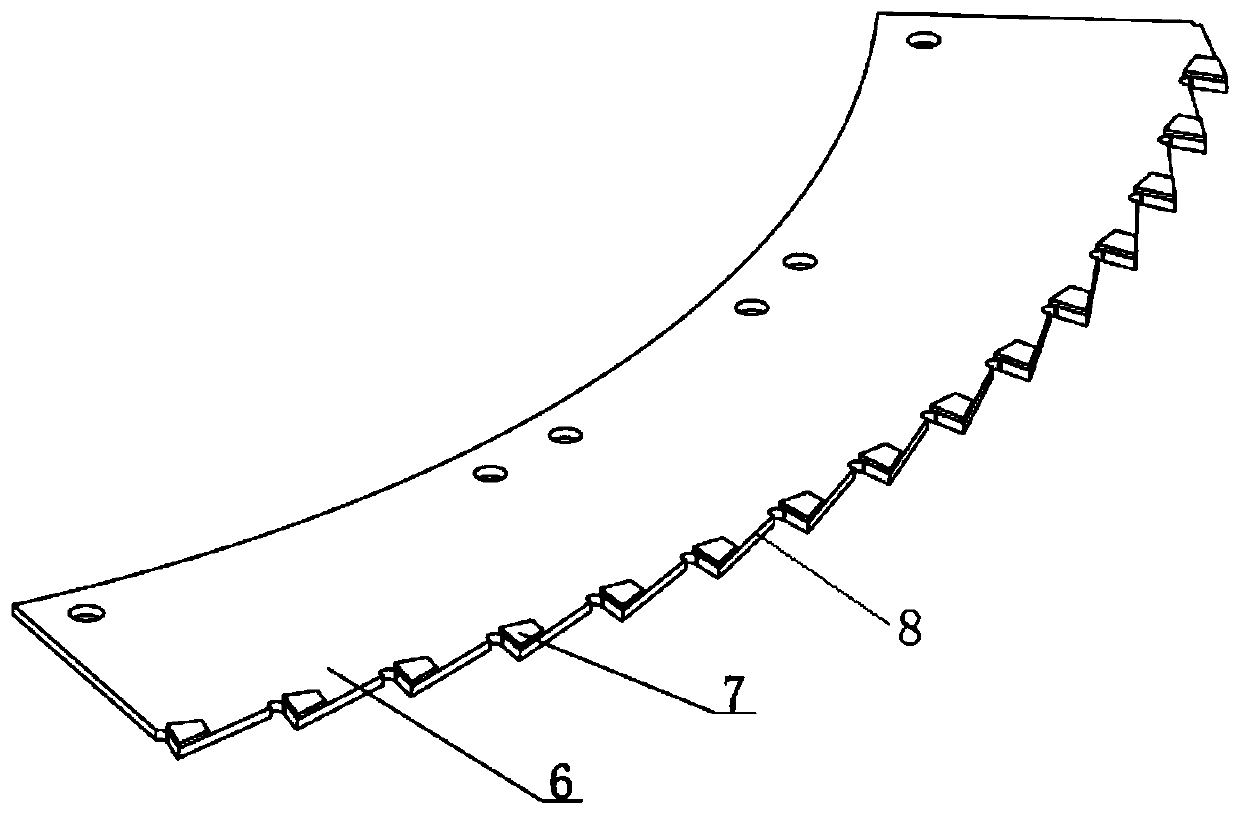

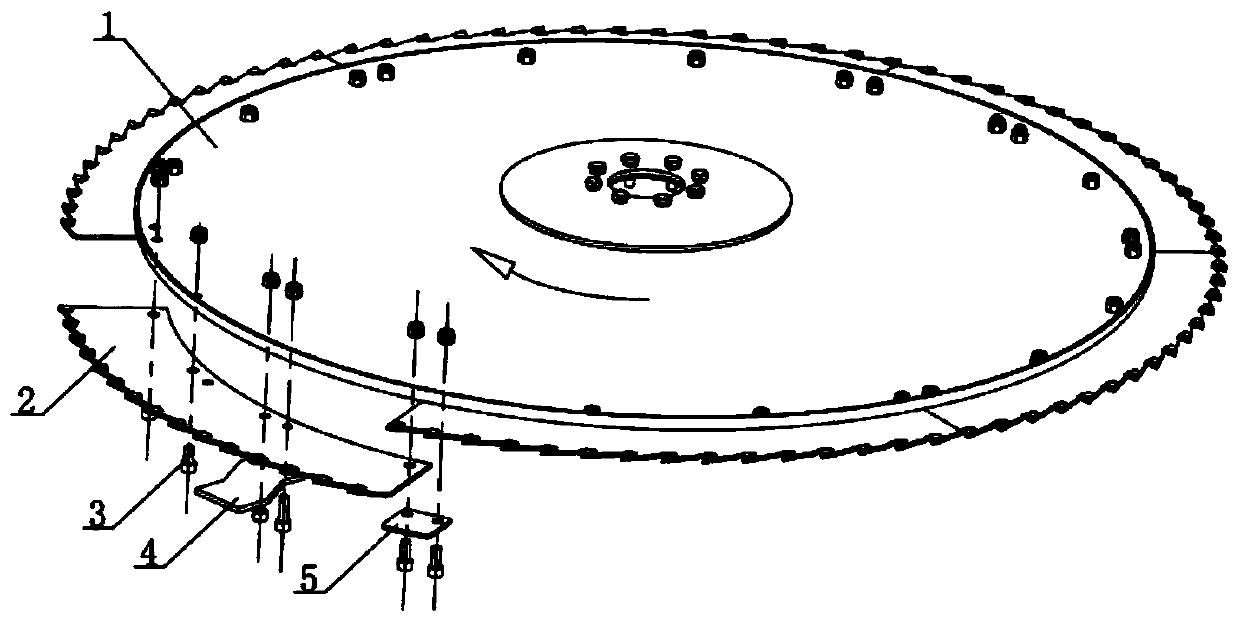

[0031] Attached below figure 1 - attached figure 2 The cutting tool and cutting disc disclosed in this embodiment are further described;

[0032] Refer to attached figure 1 As shown, the cutting tool for the silage machine includes a cutting tool body 6 and a blade 7 .

[0033] The cutting knife body 6 is a fan ring, and the working end of the outer edge of the cutting knife body 6 fan rings is provided with a sawtooth structure 8, and the upper surface of each sawtooth tip of the sawtooth structure 8 is provided with a block blade 7, and the hardness of the knife edge 7 is greater than that of the cutting knife body 6. Hardness to allow cutting knives to self-sharpen during operation.

[0034] The blade 7 and the cutter body 6 are fixedly connected into one body, and the two can be connected by welding.

[0035] The thickness of the blade 7 is smaller than that of the sawtooth structure 8, and the cutting tool adopts a high-speed impact cutting method to harvest straw. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com