Double-sided radiation acoustic exciter

A technology of radiating sound and exciter, which is applied in the direction of sensors, TVs, color TV parts, etc., can solve the problem of inability to enhance the sense of low-frequency volume and low-frequency radiation quality, limited speaker unit structure and installation position, and inability to further reduce the thickness of the whole machine and other problems, to achieve the effect of improving the sense of hearing, bearing high power, and meeting the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific drawings and embodiments.

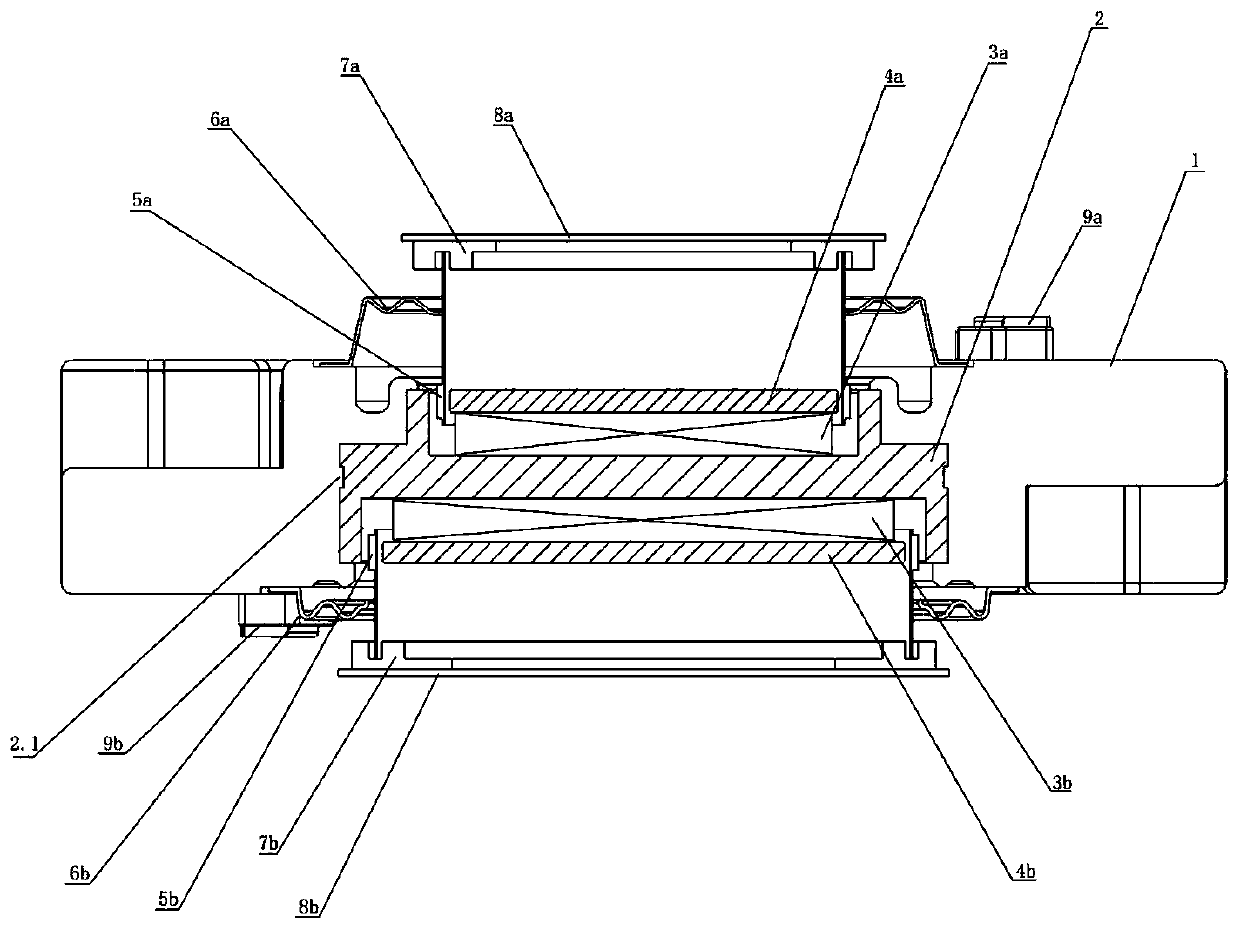

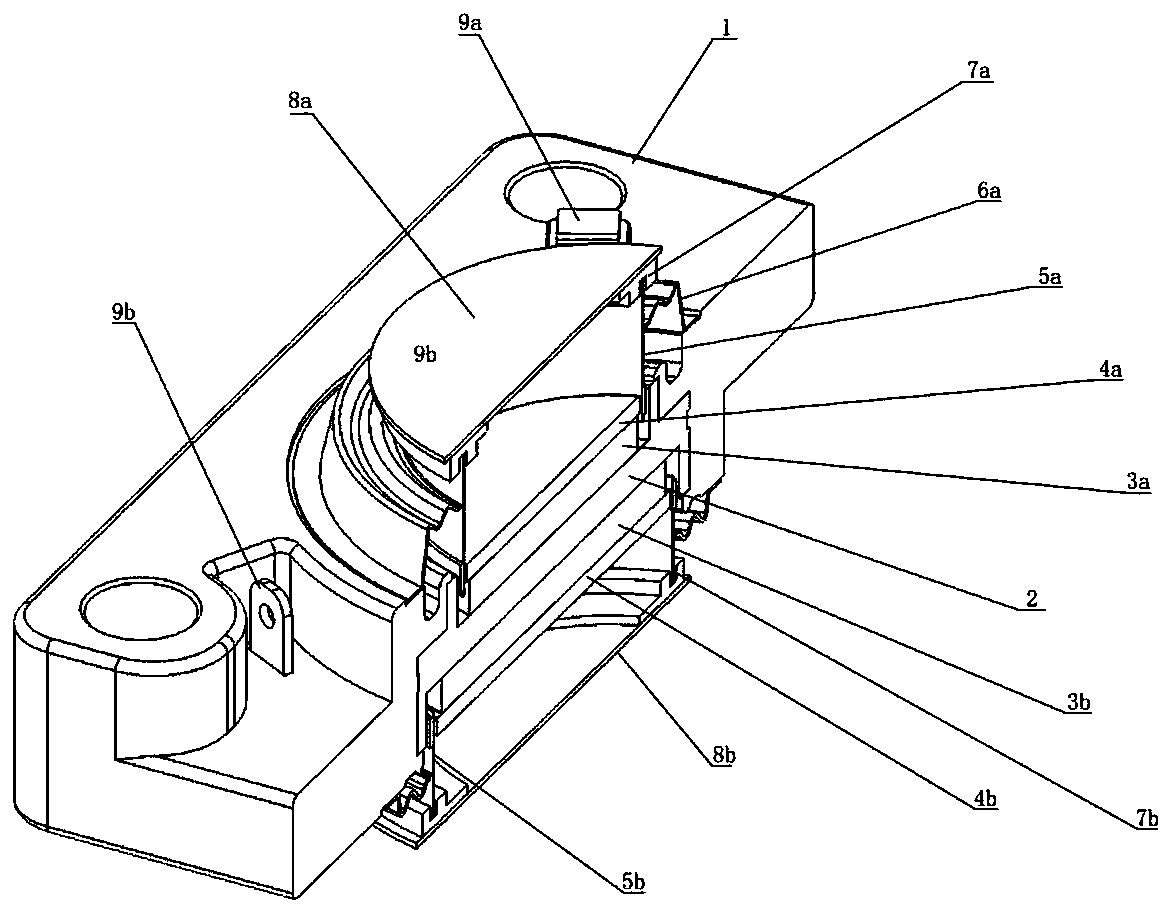

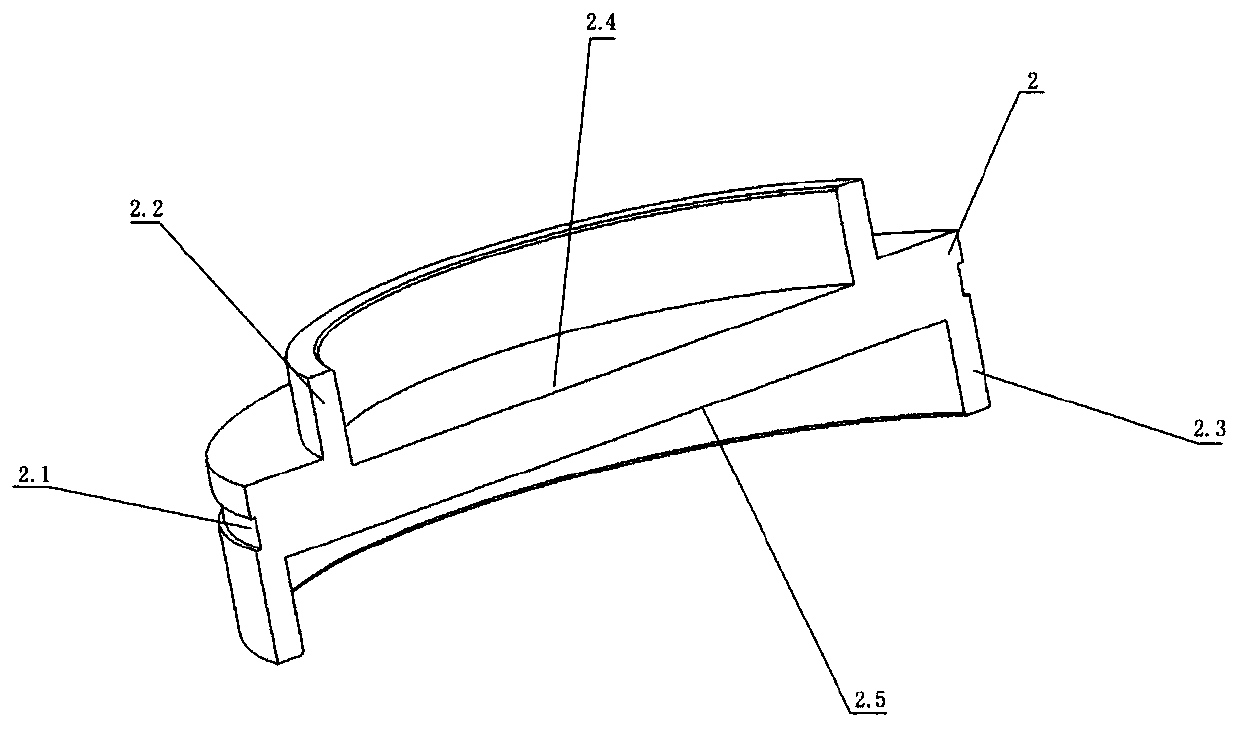

[0022] Such as Figure 1~Figure 4 As shown, the double-sided radiation acoustic exciter in the embodiment includes a pot frame 1, a bidirectional magnetic yoke 2, a first magnet 3a, a first magnetic pole core 4a, a first voice coil 5a, a first positioning strut 6a, a first The bearing ring 7a, the first flat plate 8a, the first terminal post 9a, the second magnet 3b, the second magnetic pole core 4b, the second voice coil 5b, the second positioning strut 6b, the second bearing ring 7b, and the second flat plate 8b , the second terminal 9b, the bidirectional guide yoke 2 is embedded in the pot frame 1;

[0023] A first magnet 3a is arranged directly above the first bottom 2.4 on one side of the bidirectional guide yoke 2, and a first magnetic pole core 4a is arranged directly above the first magnet 3a. On the first inner wall 2.2 of the bidirectional guide yoke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com