Horizontal type VPX module debugging device

A module debugging, horizontal technology, applied in the field of debugging devices, can solve the problems of increased VPX interface wear, increased equipment development cycle, repeated insertion and removal of VPX modules, etc., to ensure mechanical service life, easy to carry or transport, and structural weight reduction. optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

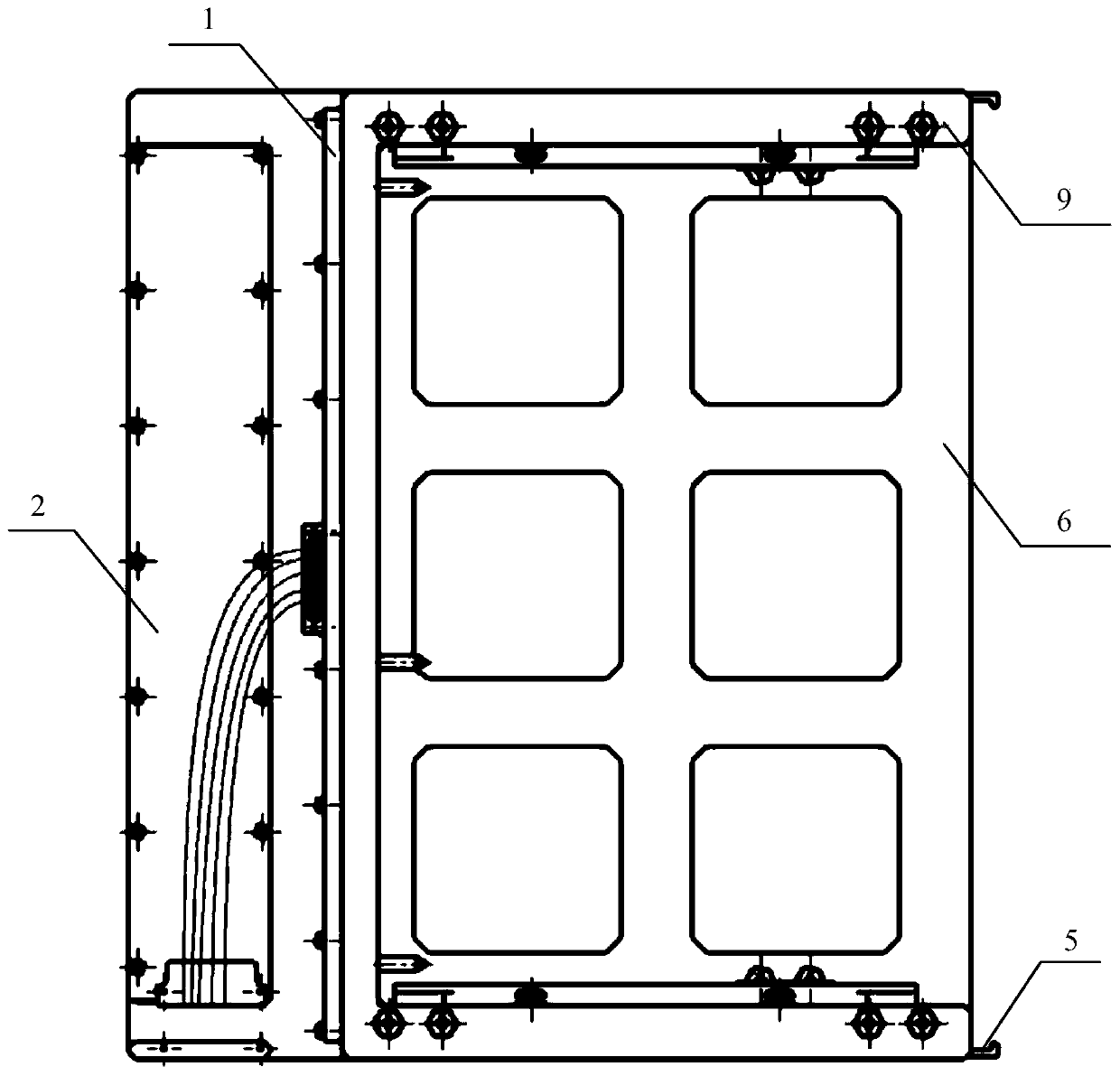

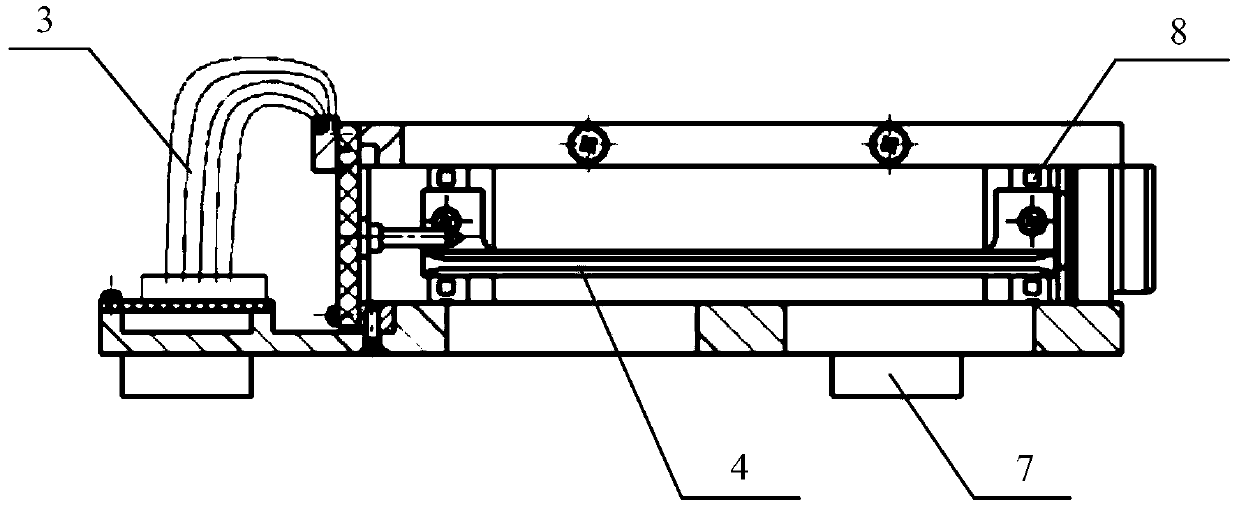

[0011] 1. The VPX module interface board is designed and installed on the interface socket and micro-rectangular socket adapted to the VPX module to be tested. The power and control signals are sent to the micro-rectangular socket. The VPX module interface board is installed vertically at the rear of the horizontal VPX module mounting frame. ;

[0012] 2. The power supply and control adapter board are designed and installed with voltage stabilizing circuit, dial switch circuit, light-emitting diode circuit and micro-rectangular socket. The power supply and control signal are sent to the micro-rectangular socket, and the power supply and control adapter board are installed horizontally. On the bottom plate of the VPX module mounting frame;

[0013] 3. The VPX module interface board and the power supply and control adapter board are interconnected through the micro rectangular socket connection cable;

[0014] 4. A pair of guide rails and upper and lower cross beams are installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com