Magnetic particle flaw detector being compatible with several types of torsion bars

A technology of magnetic particle flaw detection and torsion bar, which is applied in the direction of material magnetic variable, etc., can solve the problems affecting the efficiency of various types of torsion bar flaw detection and the fixation of various types of torsion bars, so as to achieve safe and convenient use, wide application range, The effect of reducing sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

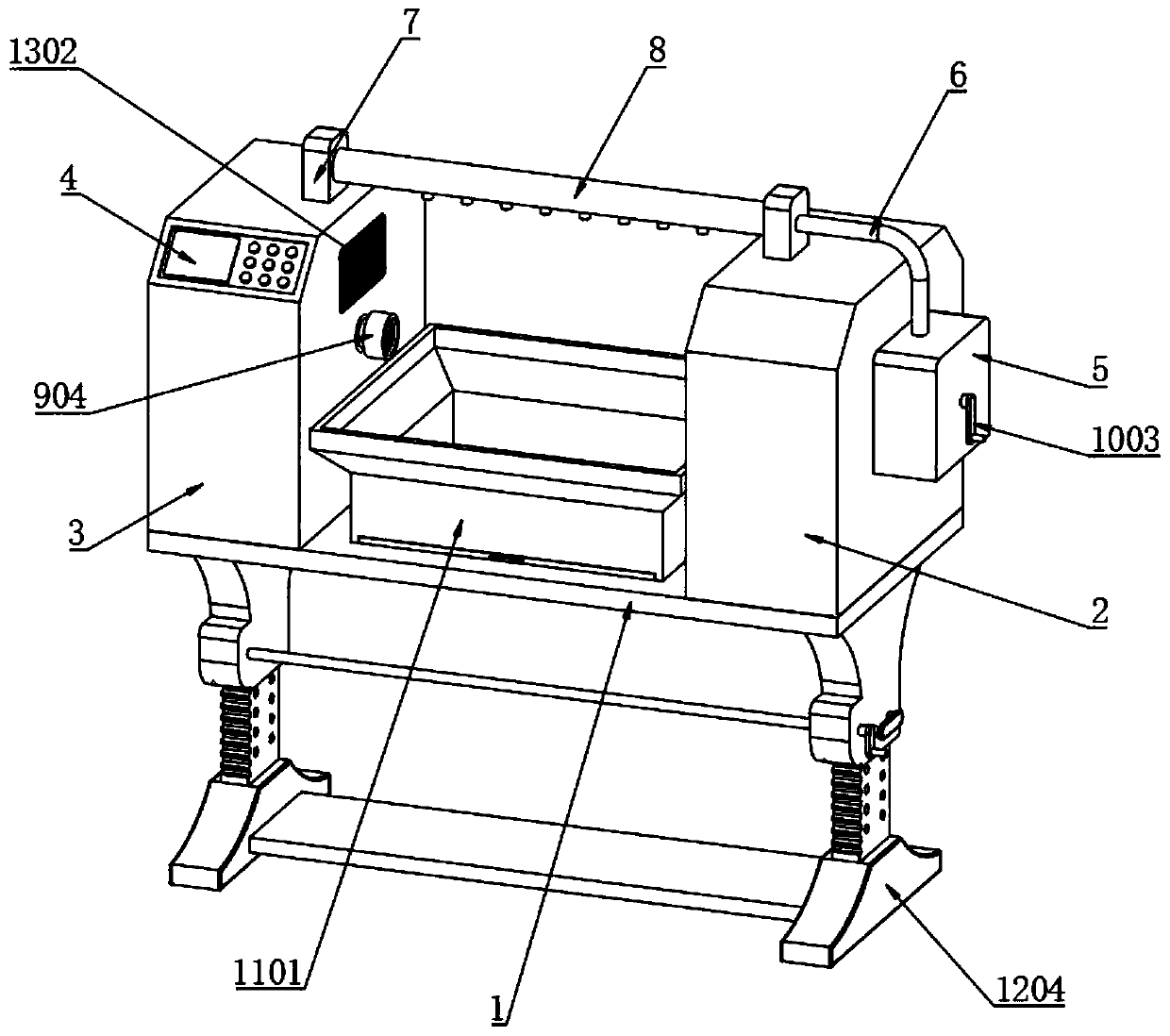

[0046] Example: such as Figure 1-8 As shown, the present invention provides a technical solution, a magnetic particle flaw detection machine that takes into account various types of torsion bars, including a work table 1, a first side plate 2 is installed on the top of the work table 1, and the top of the work table 1 corresponds to the first side plate 2 A second side plate 3 is connected to one side, and a control switch 4 is embedded in the top of the second side plate 3. One end of the first side plate 2 is connected to a magnetic powder liquid storage bin 5, and the top end of the magnetic powder liquid storage bin 5 is connected to There is a transmission pipe 6, the tops of the first side plate 2 and the second side plate 3 are connected with a mounting plate 7, and a flaw detection nozzle 8 is connected between the two mounting plates 7;

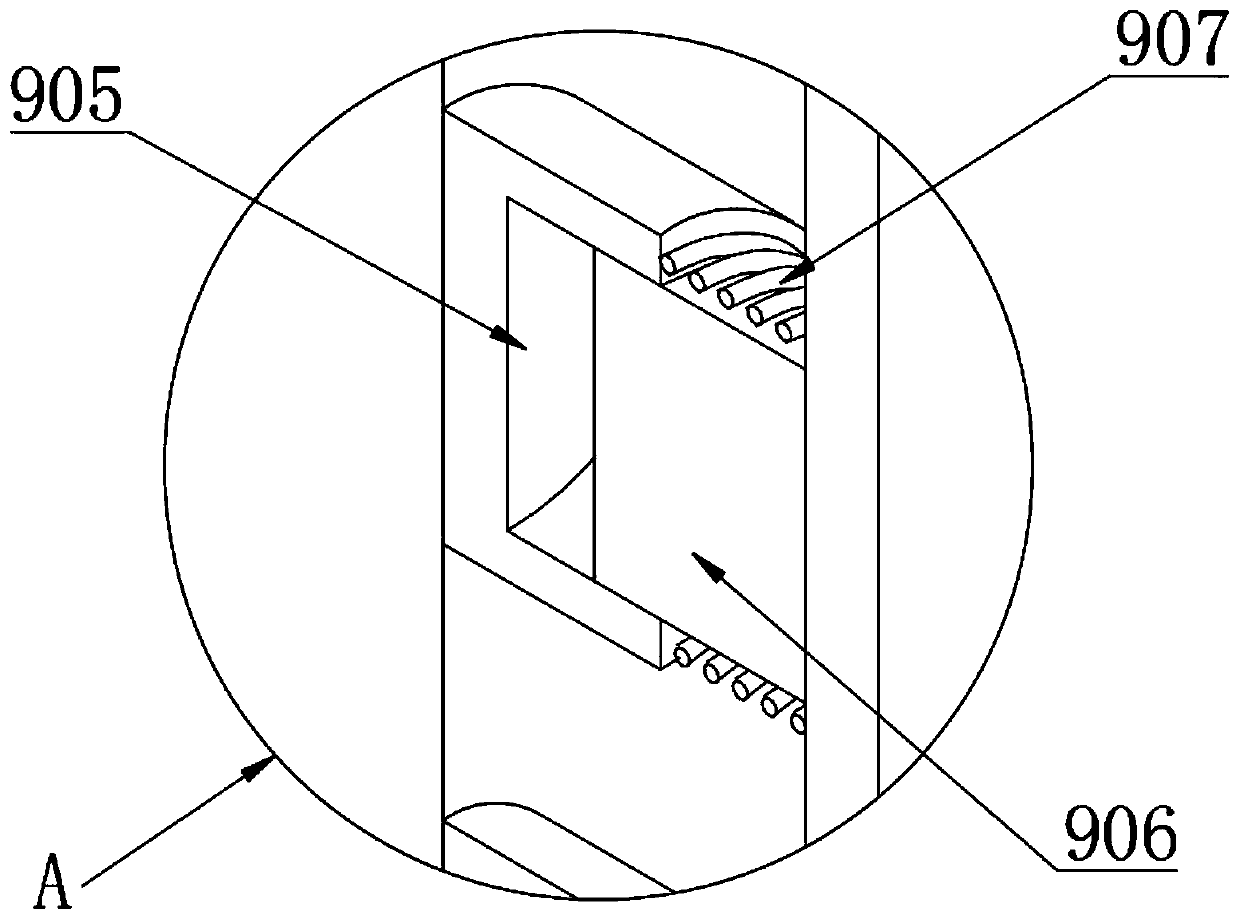

[0047] One end of the first side plate 2 is embedded with a torsion bar fixing mechanism 9. The torsion bar fixing mechanism 9 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com