The heat recovery system and selection method of the ring coating on the wall of the rotary kiln

A heat recovery and rotary kiln technology, applied in the field of heat transfer, can solve the problems of high energy consumption and low energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

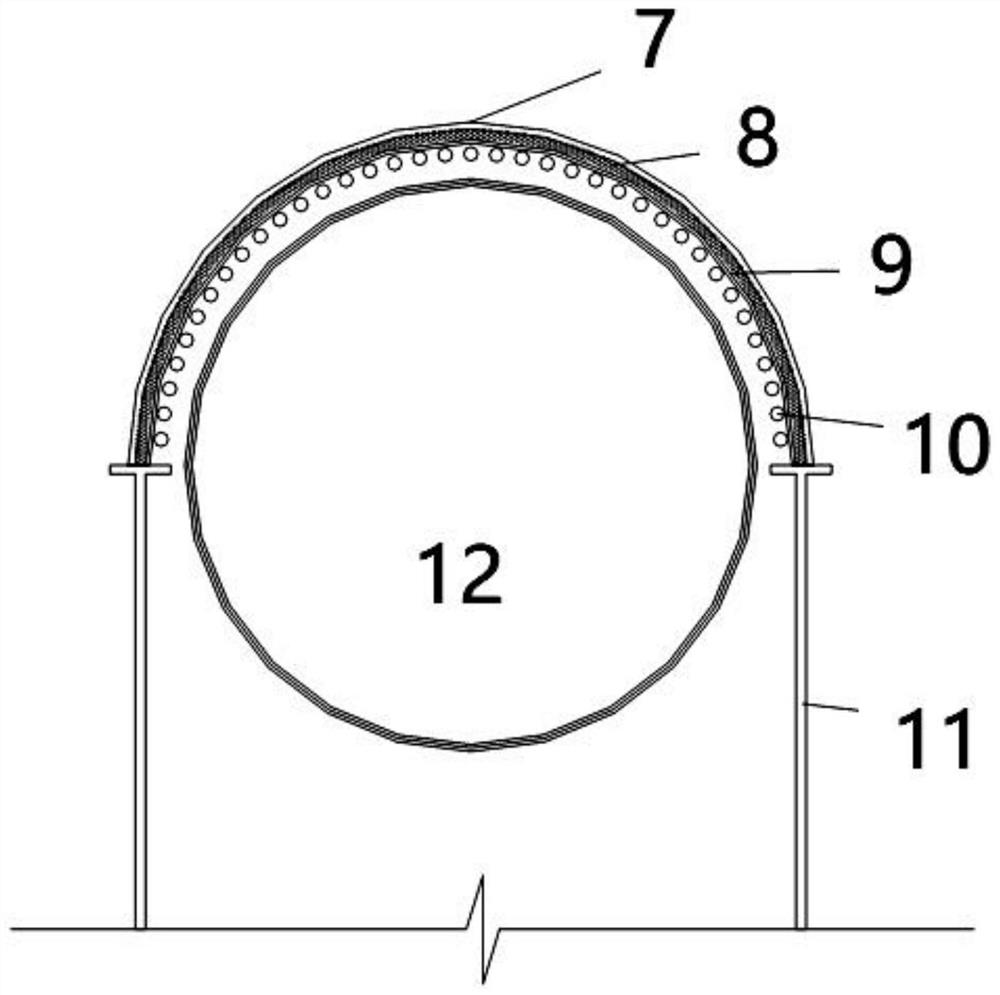

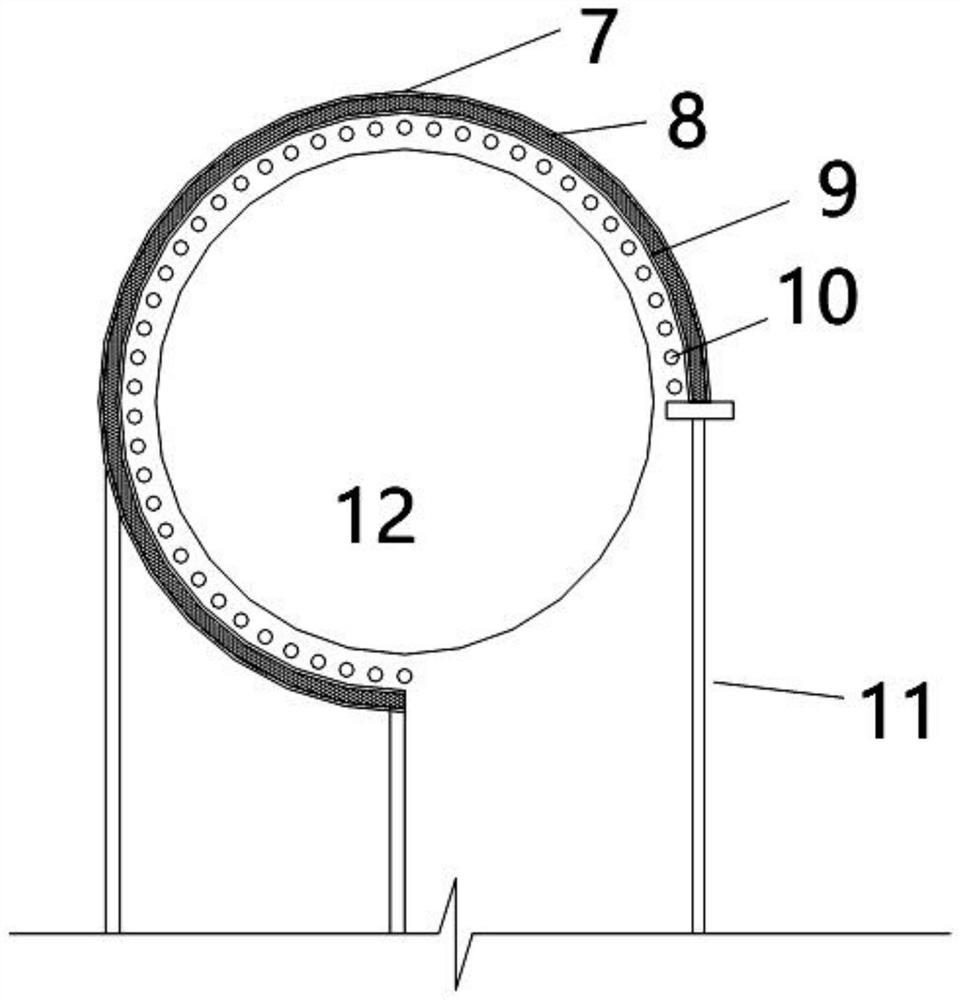

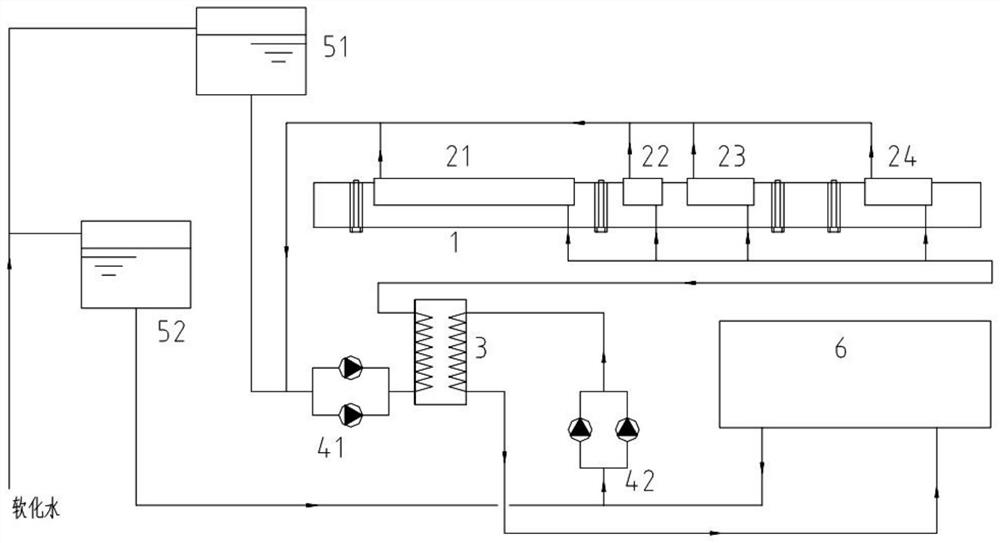

[0062] Example 1: Combining figure 1 and figure 2 ; The heat recovery system applied on the wall of the rotary kiln is characterized in that the recovery system includes a rotary kiln 1, and the rotary kiln 1 can be supported by a bracket 11; the wall of the rotary kiln 1 is arranged from the outside to the inside. Outer protection steel plate 7. Insulation layer 8, reflection plate 9, heat exchange tube 10, wall surface of rotary kiln; the heat exchange tube 10 is a tube-and-tube heat recovery device, and the tube-and-tube heat recovery devices are arranged in parallel or in series; The type heat recovery device can exchange heat with the water of the heat user to supply the heat user. The substantive technical effect and realization process of the technical solution here are as follows: This part provides a specific realization structure and realization method, and the temperature of the wall surface of the rotary kiln is relatively stable and has high quality. For exampl...

Embodiment 2

[0064] Embodiment 2: As a further improved solution or parallel solution, the heat exchange tube 10 is connected with a constant pressure water supply device 1 51 , and the constant pressure water supply device 1 51 can supply water to the heat exchange tube 10 .

Embodiment 3

[0065] Embodiment 3: As a further improved solution or a parallel solution, the circulation pipeline of the heat user is connected to the second constant pressure replenishment device 52, and the second constant pressure replenishment device 52 can supply water to the circulation pipeline of the heat consumer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com