Automatic gearbox built-in electronic gear shifting hydraulic system and control method thereof

A technology of automatic transmission and electronic shifting, which is applied in transmission control, components with teeth, belts/chains/gears, etc. It can solve the problems of unfavorable oil circuit mechanical self-locking, complicated oil circuit connection, poor reliability, etc. , to achieve the effects of enhanced shift reliability, improved driving automation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

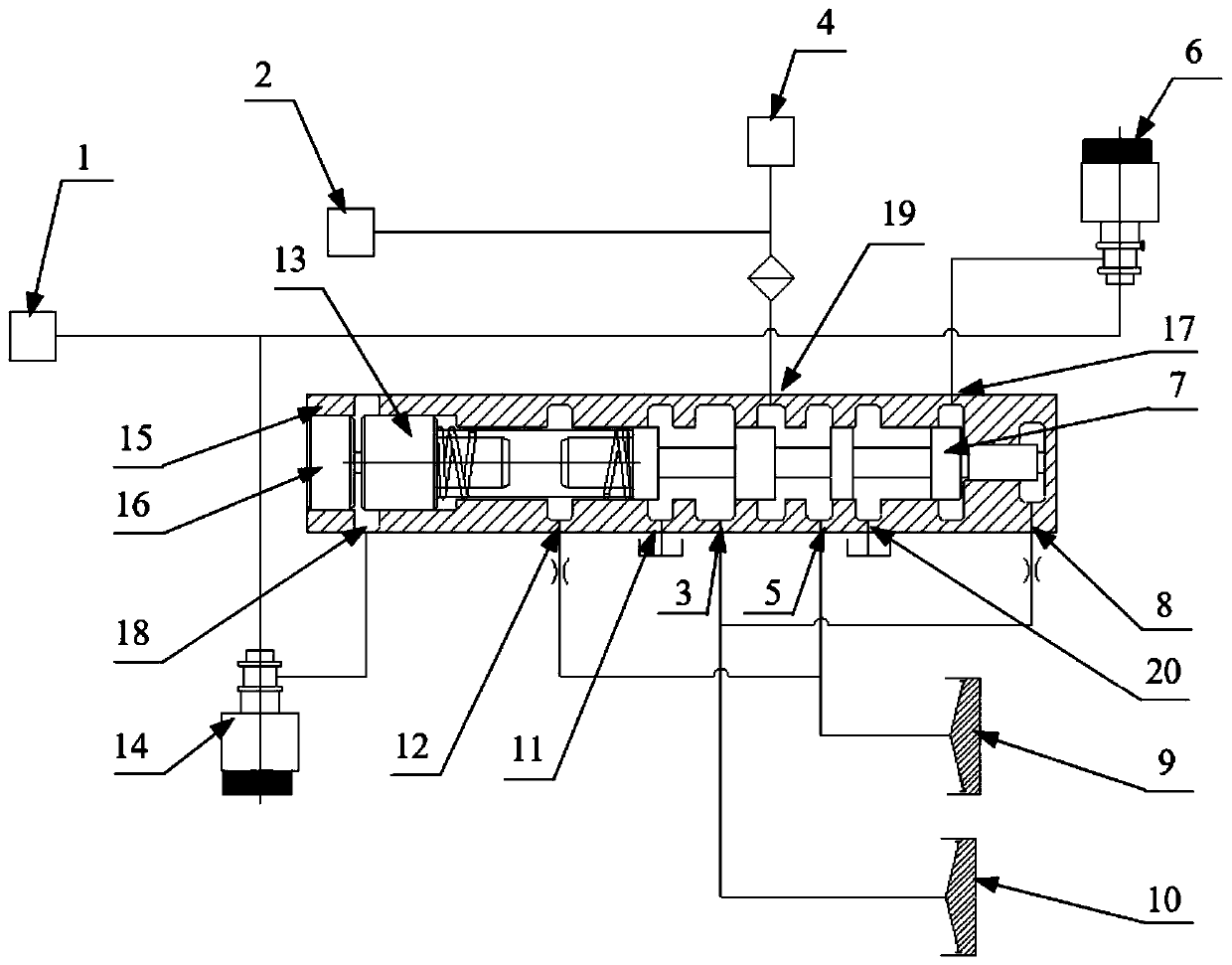

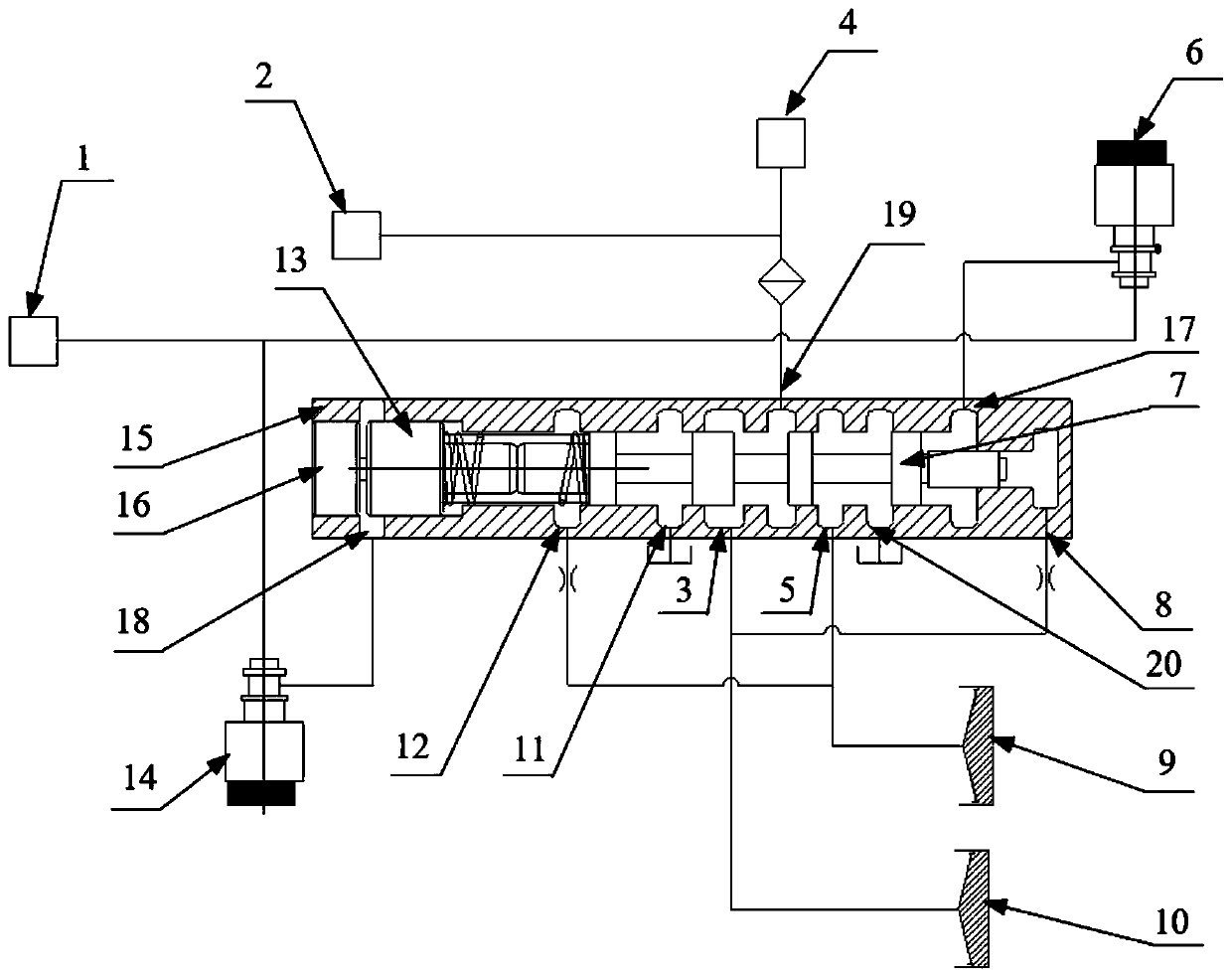

[0038] A built-in electronic gear shifting hydraulic system for an automatic transmission, including a D / N / R gear shifting mechanism, a gear shifting electronic control valve, an actuator, an oil supply chamber, and an oil circuit; the D / N / R gear shifting mechanism includes a valve body 15, a shift valve core 7 and a limit valve core 13, a spring, and an end plug that cooperate with the valve body 15 to form at least one sealing section; the inner cavity of the valve body 15 is provided with three steps of different diameters, It gradually decreases from left to right, and is used to cooperate with valve cores of different diameters to play a limiting role. There are oil i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com