Shield tunneling machine cutter with cushion device

A buffer device and shield machine technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of affecting the flow of muck, large cutters, and increased costs, so as to reduce the probability of cutter chipping and structure Simple, easy-to-make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the scope of protection of the present invention is not limited to the following examples, that is, any simple equivalent changes and modifications made based on the patent scope of the present invention and the content of the description are still within the scope of the patent of the present invention.

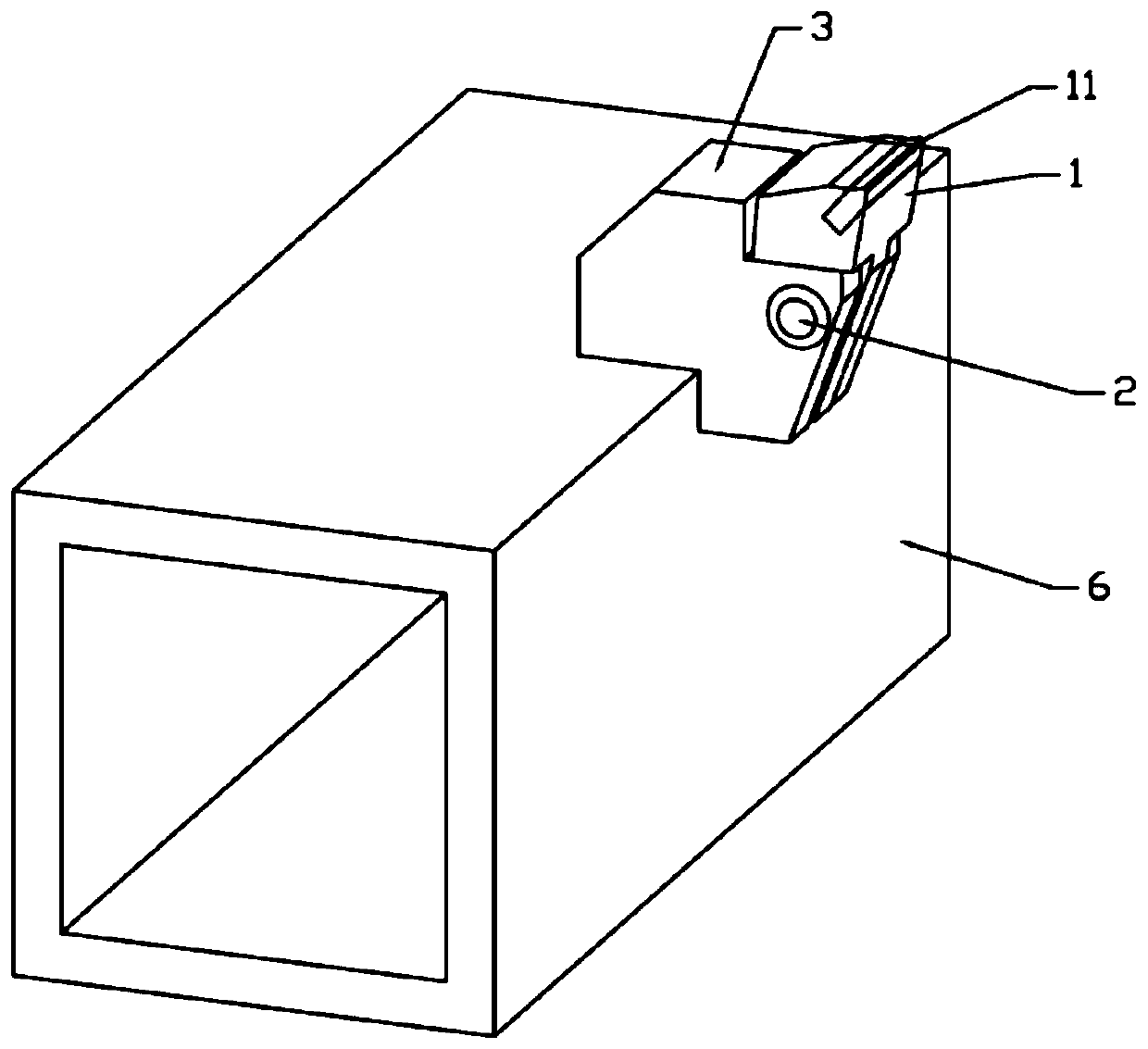

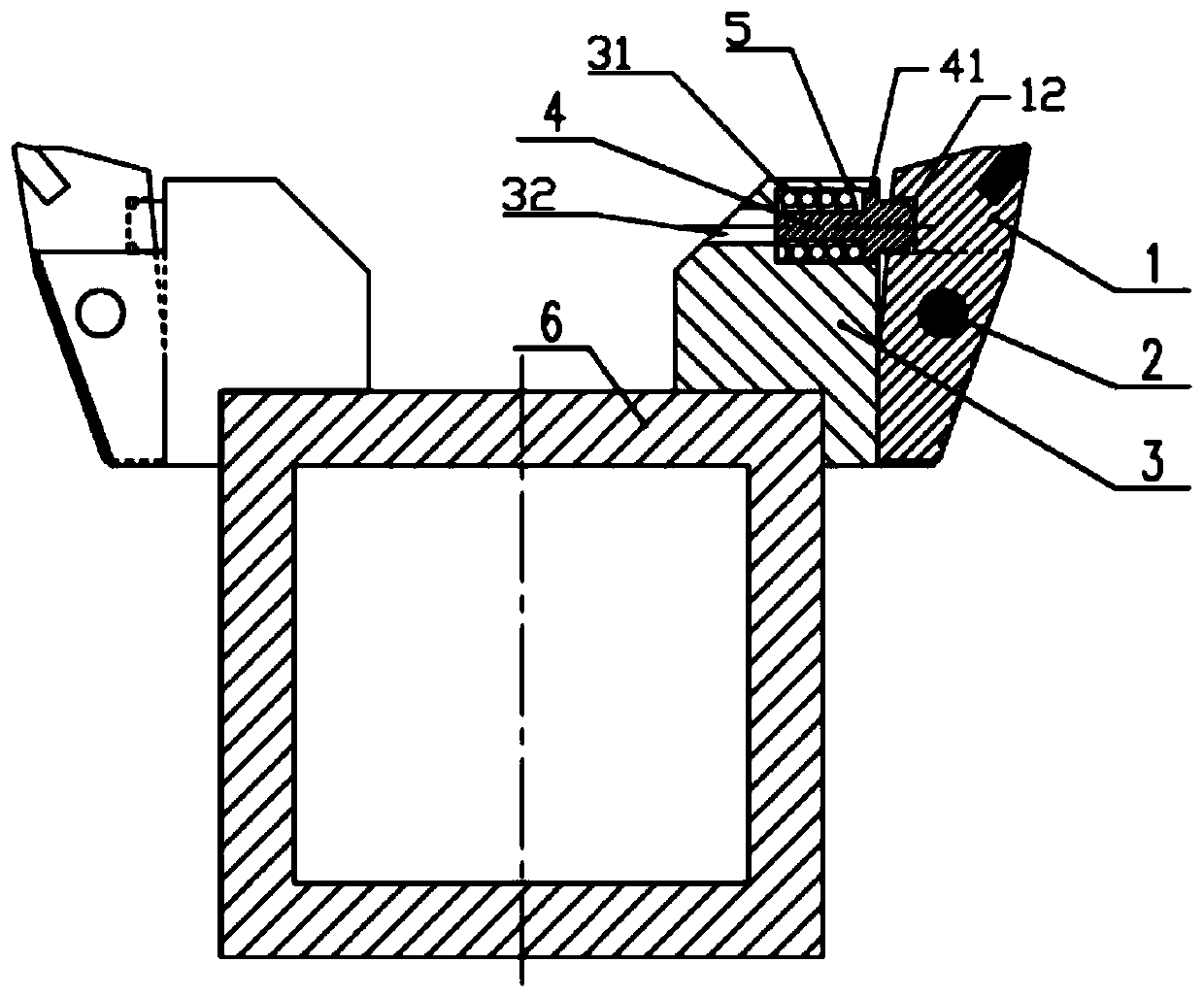

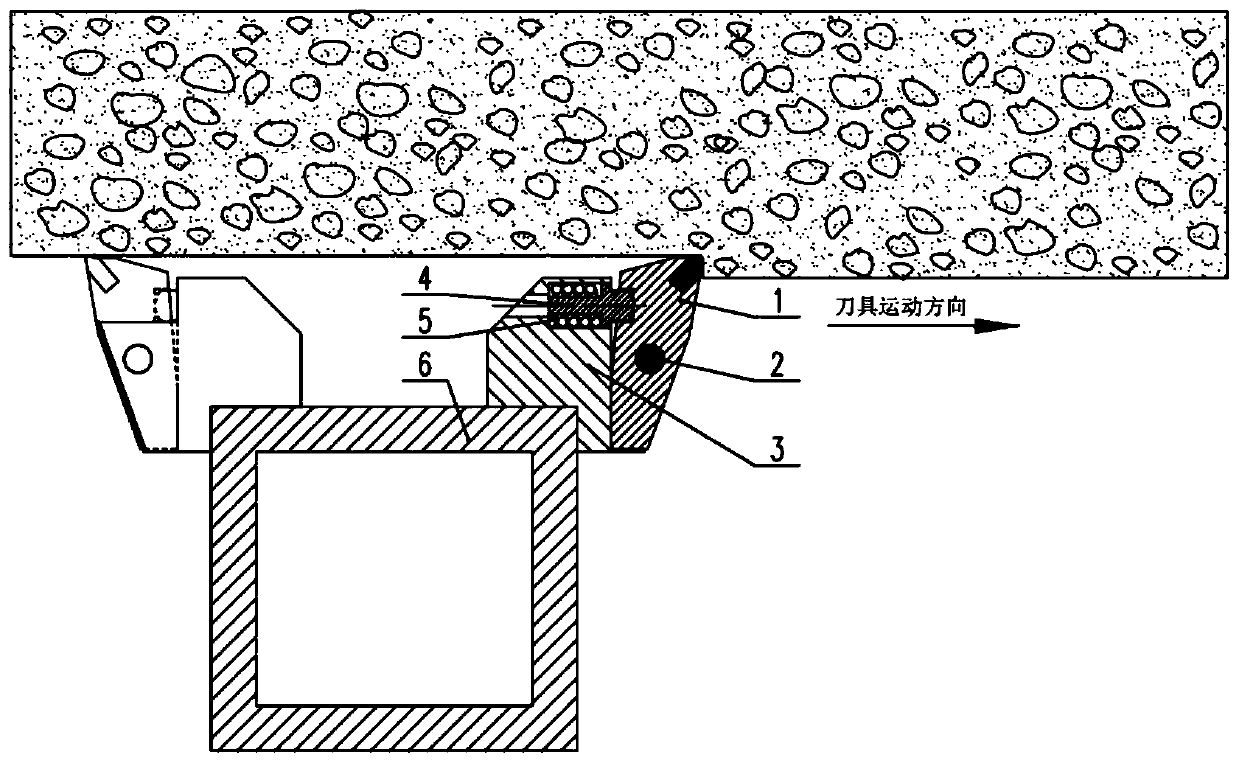

[0023] refer to Figure 1-3 , is a shield machine cutter with a buffer device according to the present invention, including a cutter seat 3 fixed on the spoke 6 of the shield machine cutter head and a cutter 1 installed on the cutter seat, the The cutting knife is provided with a cutting edge 11, and the cutting knife is positioned at the side of the cutting edge that is close to the advancing direction of the cutting knife and is connected to the cutter seat by rotation. There is a gap between the other side of the cutter and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com