Integral assembly of large formwork narrow space wall and construction method

A construction method and large formwork technology, applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, and preparation of building components on site, which can solve difficult problems such as fast connection of formwork, positioning pull screw Problems such as low-damage connection and efficient maintenance of concrete can reduce the difficulty, reduce the difficulty of installation and dismantling, and improve the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Concrete mix ratio design and pouring construction technical requirements, on-site hoisting construction technical requirements, section steel rolling and welding construction technical requirements, bolt fastening construction technical requirements, etc., will not be described in detail in this implementation mode, and the implementation mode of the method involved in the present invention will be focused on .

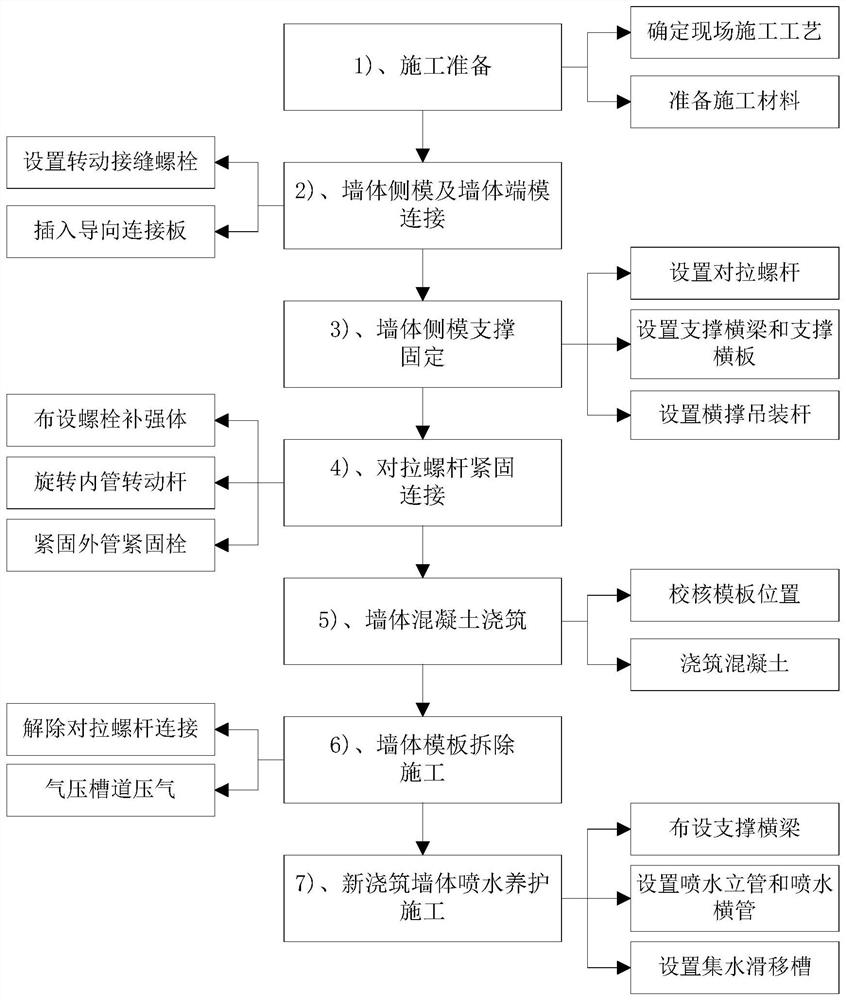

[0034] figure 1 It is the construction flowchart of the narrow space wall body of the whole assembled large formwork of the present invention, refer to figure 1 As shown, the overall assembly of large formwork narrow space walls and construction methods includes the following construction steps:

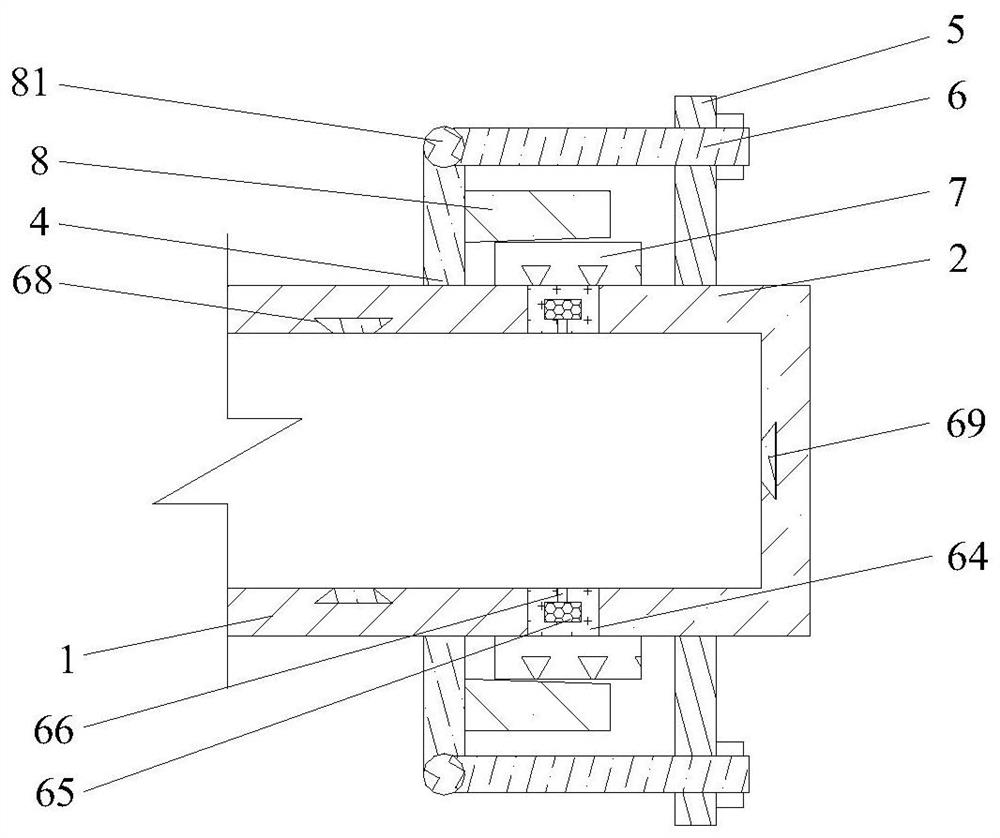

[0035] 1) Construction preparation: Prepare the wall side formwork (1), wall end formwork (2) and tension screw (3) required for construction, determine the concrete mix ratio and on-site construction technology, and prepare the materials and devices required for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com