Reinforcing device of large size arc-shaped embedded part for fixation on outer wall of silo and use method

A technology of reinforcement devices and embedded parts, which is applied to the preparation of building components on site, formwork/formwork components, construction, etc. Convenient, location-accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

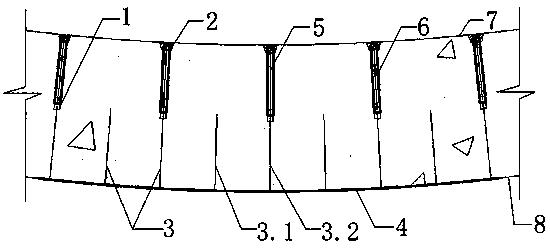

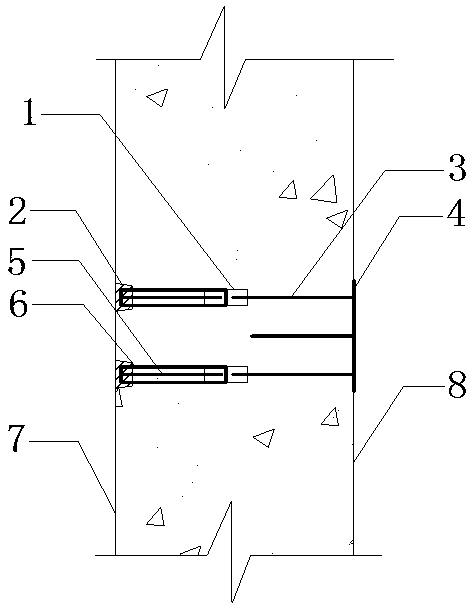

[0029] Embodiment one: by Figure 1 to Figure 4 It is given that the reinforcement device for fixing the outer wall of the silo with a large-scale arc-shaped embedded part includes a plurality of steel bars 5 and a plurality of anchor bars 3 used between the steel formwork and the embedded part 4, and the steel formwork includes an inner arc Steel formwork 7 and outer arc steel formwork 8, the large-sized embedded part is extended on the length of the ordinary embedded part, the width is basically unchanged, and its arc is pressed by a plate rolling machine; the steel formwork is a cylinder The inner arc formwork and outer arc formwork of the silo wall, the length of the steel formwork is less than the length of the large-sized embedded part, the embedded part 4 is located between the steel formwork and close to the outer arc steel formwork 8, each The anchor bar 3 includes a connecting anchor bar 3.1 with one end covered with wire and a supporting anchor bar 3.2 without a thr...

Embodiment 2

[0030] Embodiment 2: On the basis of Embodiment 1, each of the anchor bars 3 and the inner arc side of the embedded part 4 are fixed by welding, and each of the anchor bars 3 is fixed on the embedded part 4 according to the vertical distance of 90 mm and Arranged in an array with a distance of 150 mm in the horizontal direction, the horizontal distance between each of the connecting anchor bars 3.1 is 300 mm, and the end plane of the PVC pipe 6 on each of the reinforcing body units close to the anchor bar 3 is located in the positive and negative wire sleeves In the middle part of cylinder 1, the end of the PVC pipe 6 far away from the anchor bar 3 is equal to the unthreaded end of the steel bar 5, and the threaded end of the anchor bar is matched with the positive and negative wire sleeves, and the threaded end of the steel bar The ends are matched and connected with the positive and negative wire sleeves. The rubber plug 2 is a round platform with a groove. The diameter of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com