Auxiliary anchor net pressing tray and anchor net pressing method

A pallet and anchor mesh technology, which is applied in the installation of anchor rods, earthwork drilling, wellbore lining, etc., can solve the problems of incomplete anchor rod components, inconvenient installation of anchor rod discs, and small exposed length of the thread at the end of the anchor rod. Achieve the effect of complete anchor rod components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

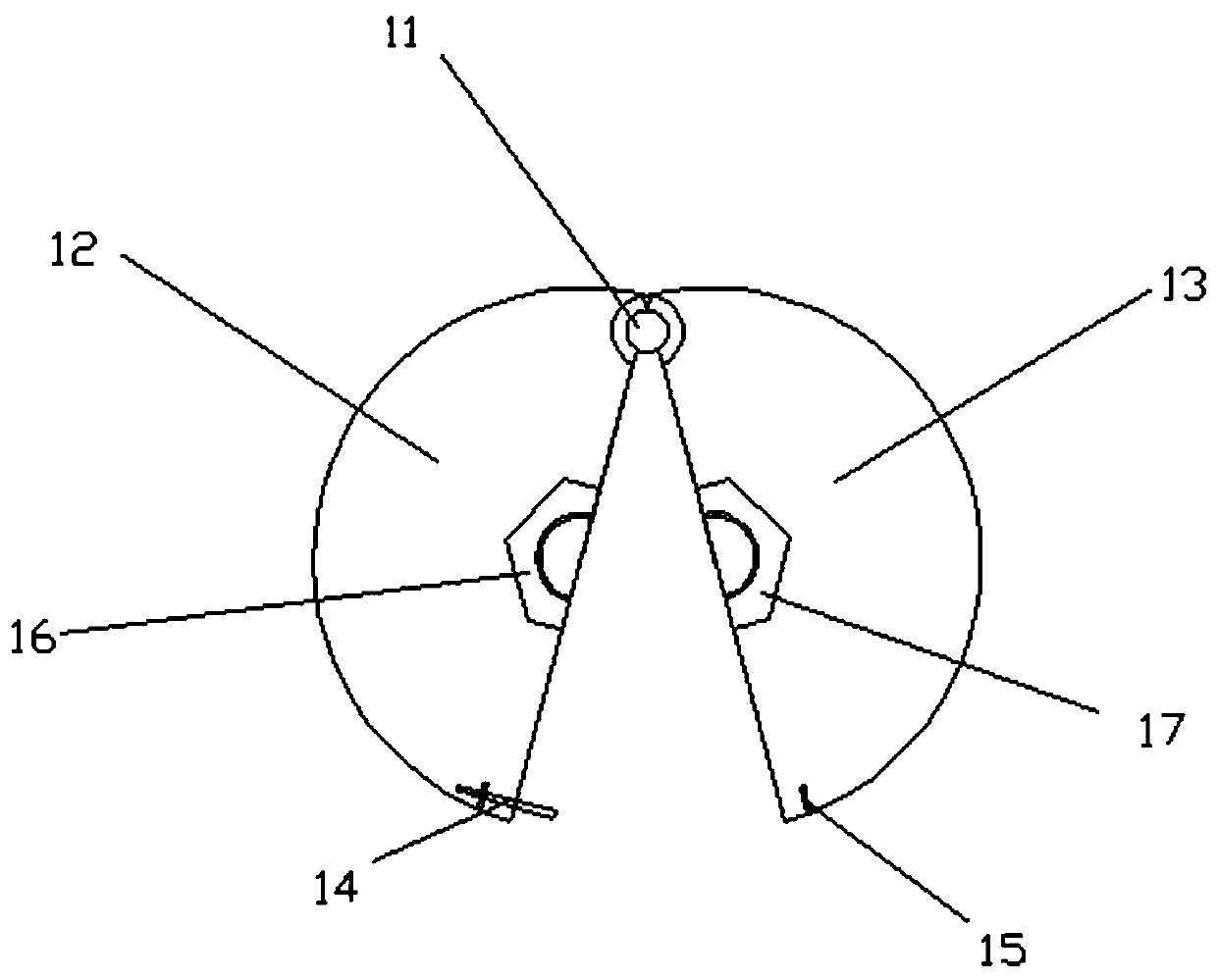

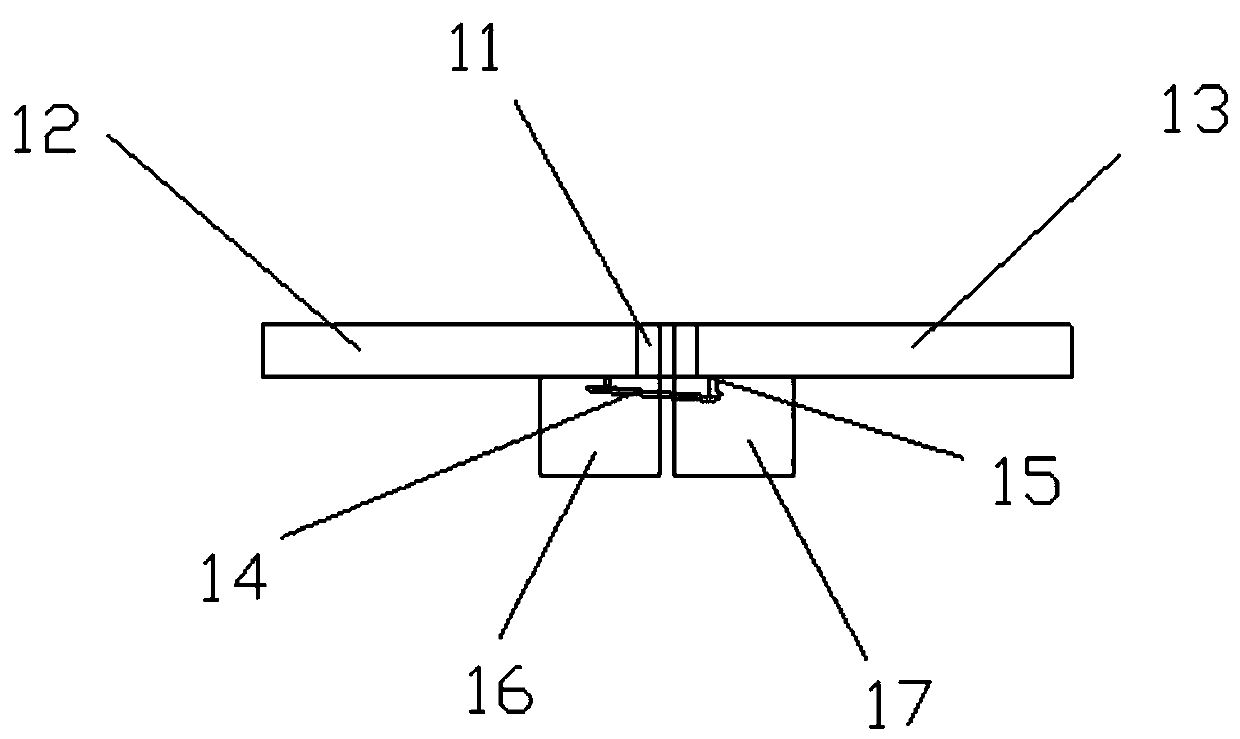

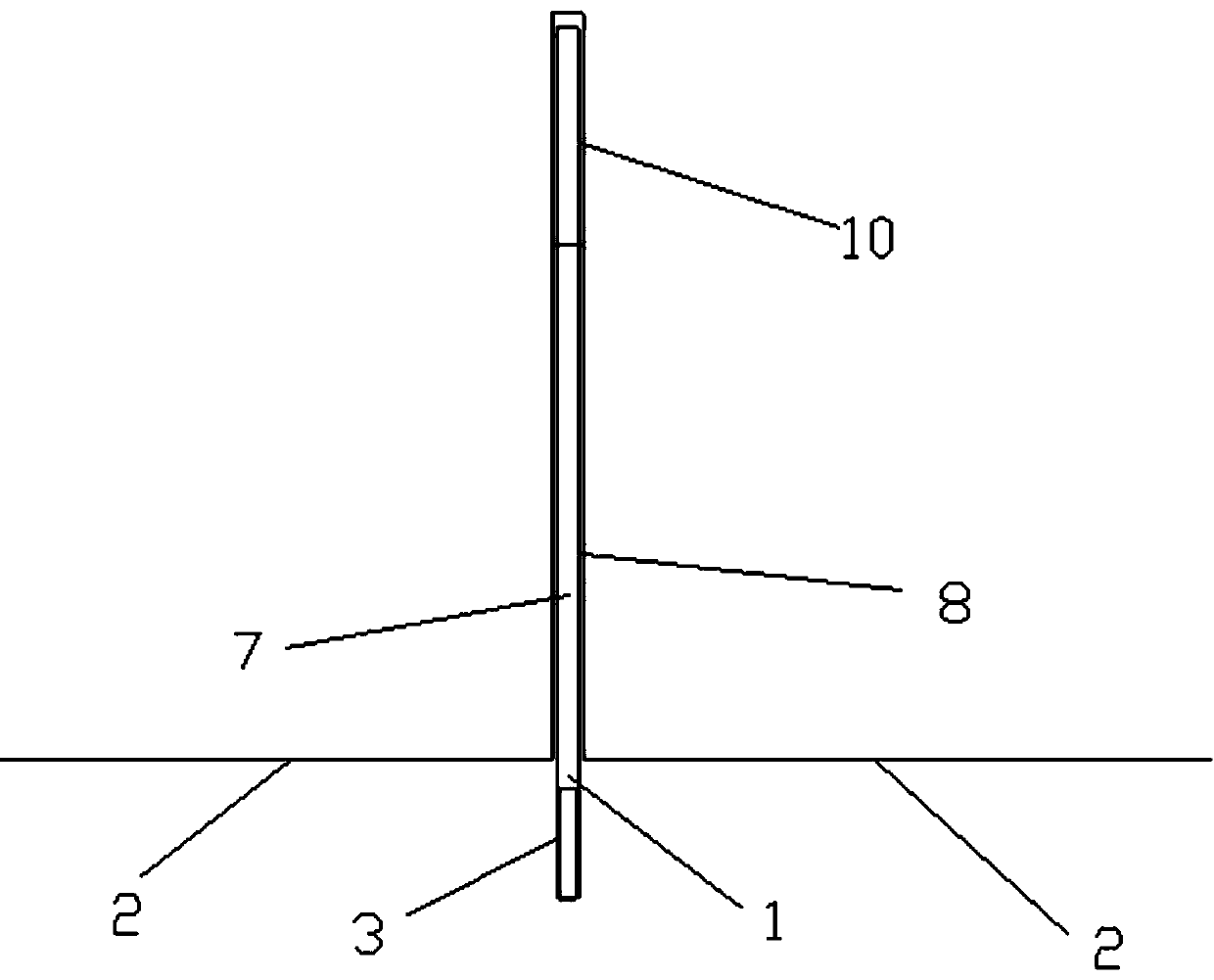

[0031] Such as figure 1 , 2 As shown in , 3, the present invention discloses an auxiliary anchor net pallet, comprising a left half nut 16, a right half nut 17 connected with the threads of the left half nut 16, and the left half nut 16 and the right half nut 17 are installed and fixed respectively On the left tray 12 and the right tray 13, after the left tray 12 and the right tray 13 are spliced together, it is ensured that the left half nut 16 and the right half nut 17 form a complete nut, and one side of the left tray 12 and the right tray 13 are set together on the The tray torsion shaft 11 can be opened and merged around the tray torsion shaft 11, the other side of the left tray 12 and the right tray 13 are respectively installed and fixed with a tension buckle pull rod 14 and a tension buckle hook 15, the left tray 12 and the right tray 13 The pull rod 14 and the hook 15 of the pull buckle are locked together.

[0032] After the left tray 12 and the right tray 13 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com