Composite pile foundation of open caisson pile adding

A composite pile foundation and caisson technology, which is applied in basic structure engineering, construction, etc., can solve the problems of inaccurate ruler position, waste of materials, construction difficulties, etc., and achieve the effect of convenient operation and speeding up the experiment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

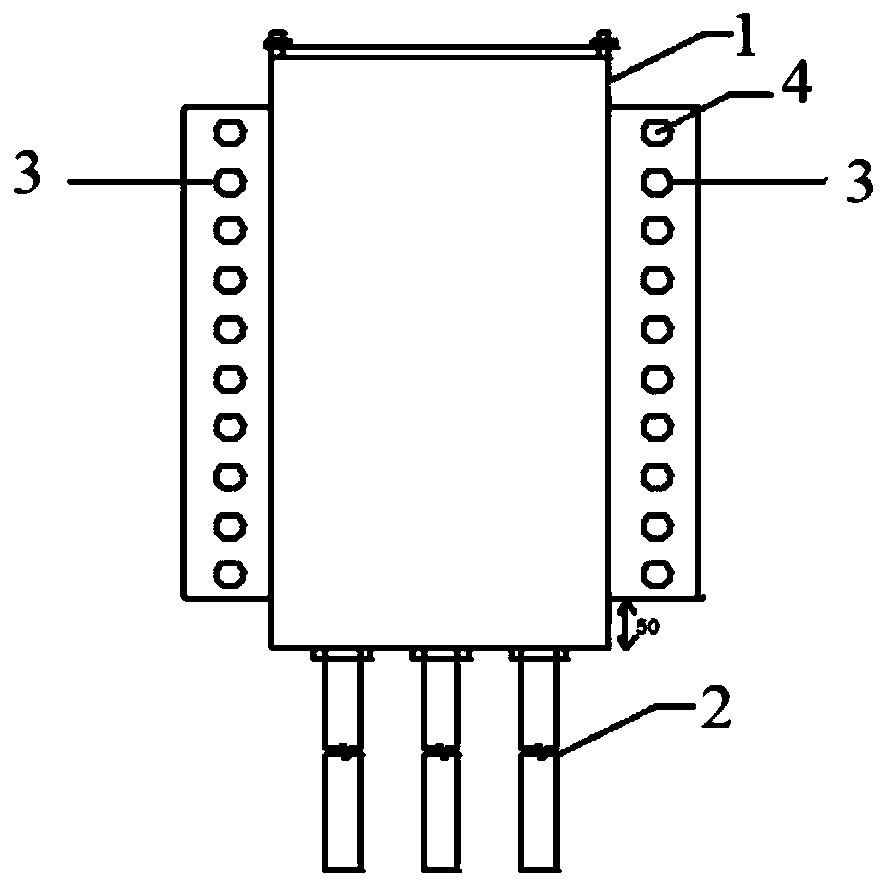

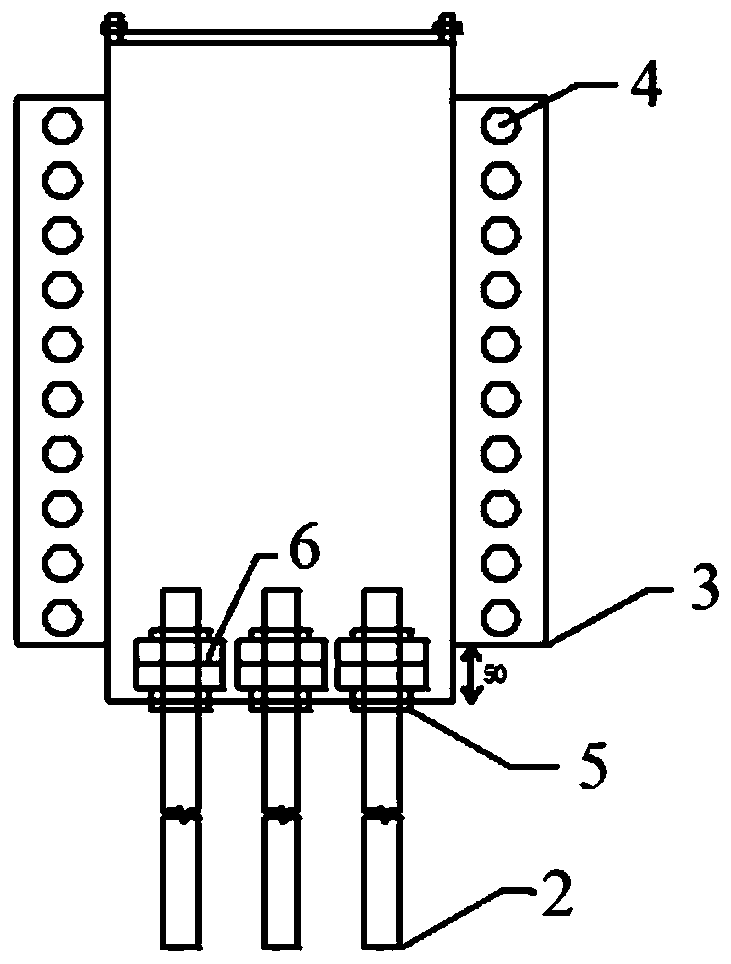

[0039] The present invention refits the original caisson foundation to form a new caisson plus pile composite foundation, such as figure 1 As shown, it includes a single caisson foundation 1, a rod made of threaded steel 2, a side wall steel plate 3 with a pull ring, and a counterweight block, wherein the single caisson foundation 1 is a single caisson with a detachable top plate Foundation, the lower center of the single caisson foundation is provided with three threaded steel rods 2, the upper end of the threaded steel rods 2 is provided with a counterweight block, and the outer wall of the single caisson foundation 1 is provided with a pulley Ring side wall steel plate 3. Specifically, the single caisson foundation 1 is a rigid foundation made of thick steel pipes (suitable size can be made according to needs), and the bottom of the single caisson foundation 1 itself needs to be sealed and reserved to match the size of the threaded steel rod 2. The corresponding hole is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com