Artificial dig-hole pile system

A technology of manual hole-digging piles and hollow piles, applied in excavation, infrastructure engineering, life-saving equipment, etc., can solve the problems of hidden safety hazards for construction personnel and material falling, and achieve the effect of improving safety and facilitating discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the drawings and embodiments.

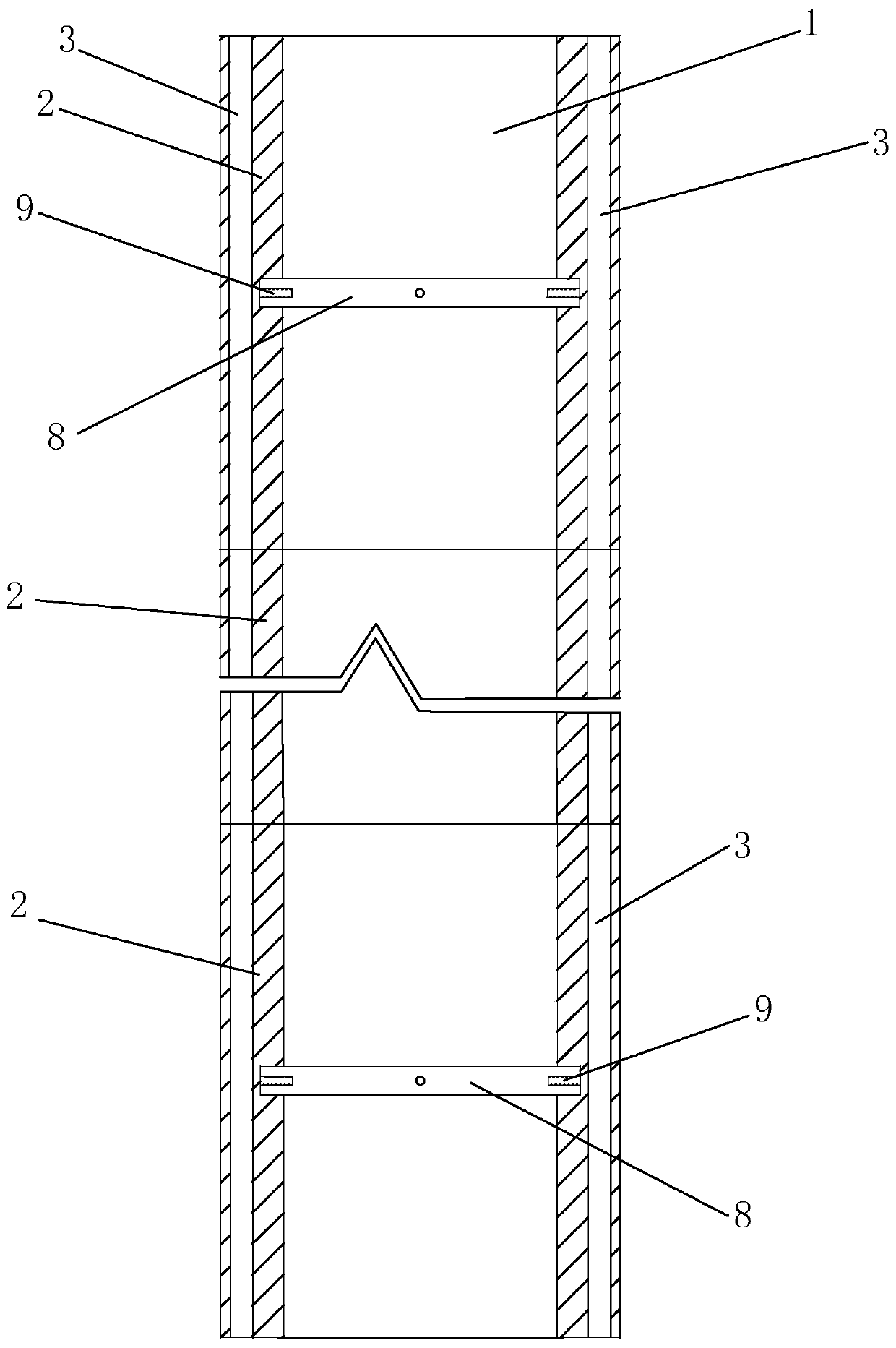

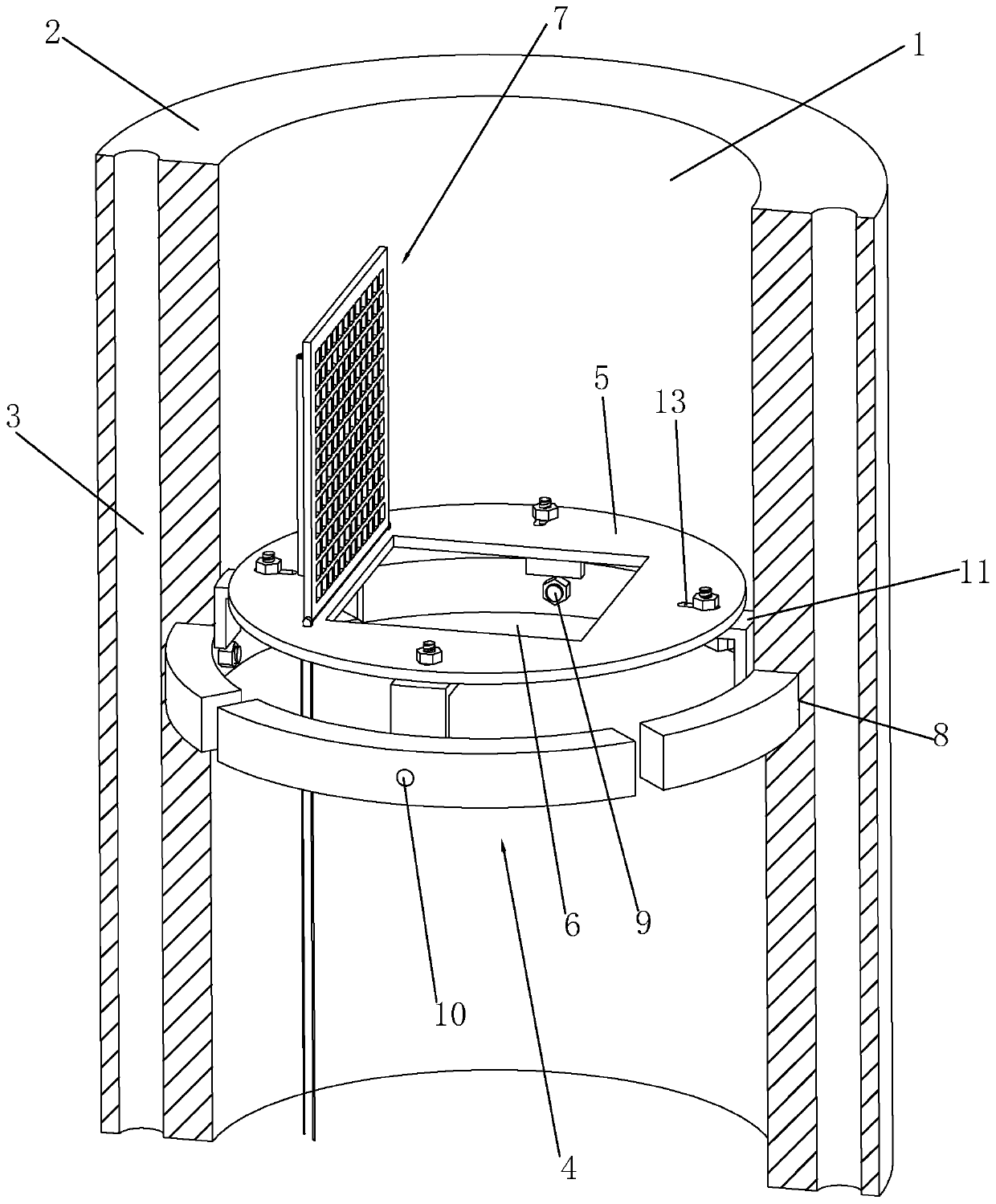

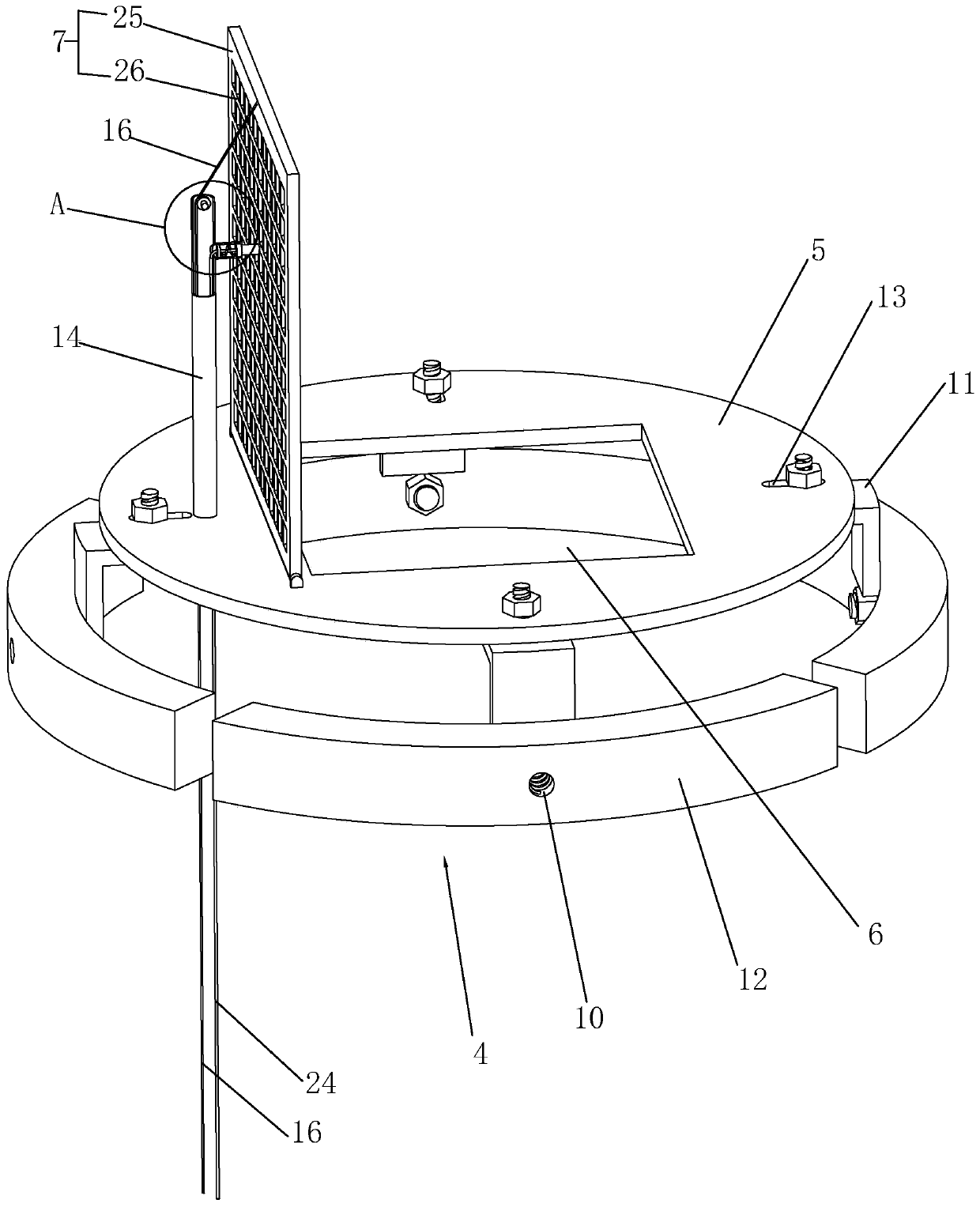

[0036] A manual digging pile system, such as figure 1 with figure 2 As shown, it includes a hollow pile hole 1 and a concrete casing 2 arranged on the wall of the hollow pile hole 1, and multiple concrete casings 2 are poured in sections from top to bottom. Two air exchange pipes 3 are pre-embedded vertically and oppositely in the concrete casing 2, and the air exchange pipes 3 in the upper and lower concrete casings 2 are connected by an adapter. By embedding two opposite air exchange pipes 3 vertically in the concrete casing 2, it is convenient to transport fresh air from outside to the hollow pile hole 1 through one of the air exchange pipes 3, and through the other air exchange pipe 3 The toxic gases and nitrogen-rich and oxygen-deficient gases in the hollow pile hole 1 are discharged, and the air exchange pipe 3 can also be used as a drain pipe, so as to facilita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com