Construction method for excavating square piles through rotary excavating machine and square chiseling head combined

A construction method and technology of rotary excavator, applied in the direction of excavation, infrastructure engineering, drilling equipment and methods, etc., can solve problems such as inability to dig square holes, limited shape of rotary excavator, etc., to avoid artificial accidents and improve safety benefits , Improve the effect of safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

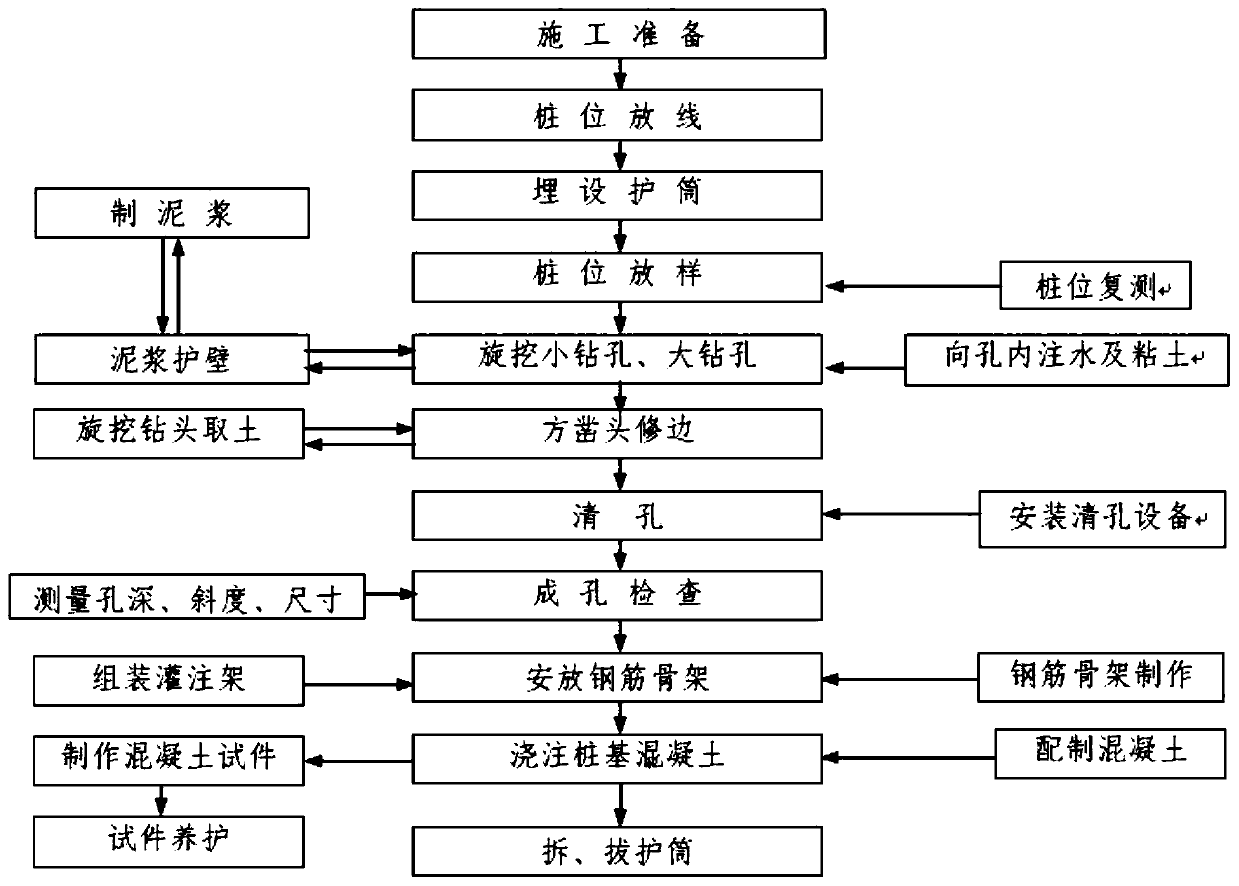

[0055] see Figure 1-12 , a kind of rotary excavator combined square chisel head excavation square pile construction method provided by the present invention, described construction method comprises the following steps:

[0056] 1) Buried casing

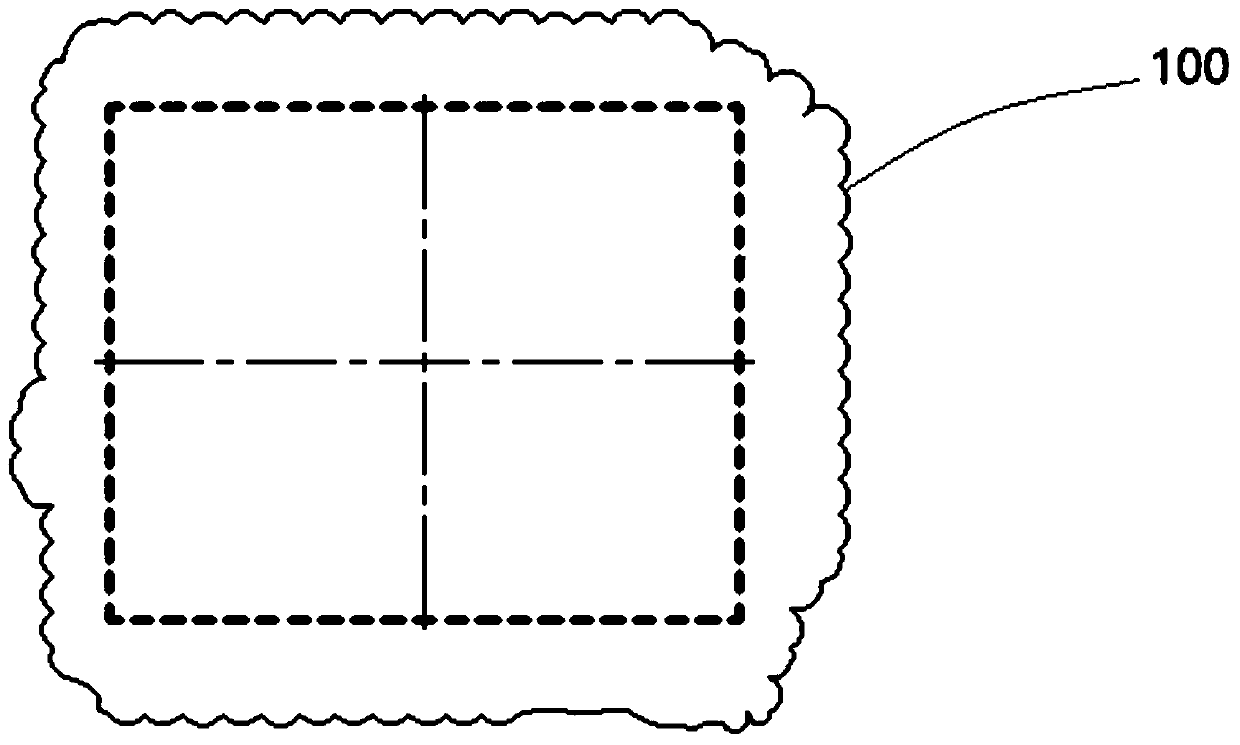

[0057] Level the site, set out the pile position, determine the pile position of the square pile, excavate a square foundation pit 100 matching the shape of the casing around the pile location of each square pile, hoist the casing 101 to the pile location, and the outer side of the casing 101 Backfill and compact all around;

[0058] Specifically, the excavator unloaded the load of the landslide body, leveled the site, and left sufficient work space for the rotary excavator, crane, and pouring concrete. After setting out the pile position and determining the position of the pile hole, excavate a square foundation pit 100 at the position of the pile hole. can be deepened), the lower end of the casing 101 is inserted into the founda...

Embodiment 2

[0118] Taking the excavation and collapse treatment on the right side of BK0+220~BK0+422.11 and EK0+000~EK0+120 of a city ring expressway in a certain place as an example, the specific construction methods are as follows:

[0119] 1. Geological conditions

[0120] 1. Brown gray, off-white expansive soil, easy to collapse when exposed to water.

[0121] 2. Part of the slope has collapsed, there are cracks on the top of the slope, and there are local villagers' houses and local road changes above the upper slope.

[0122] 2. Treatment plan

[0123] A total of 54 anti-slide piles (2.0×2.5m) are installed, the piles are 12 meters long, and the pile-slab wall is 6 meters high.

[0124] 3. The actual construction situation

[0125] The square pile was excavated with a rotary excavator combined with a square chisel head, and the excavation operation took a total of 17 days.

[0126] As a result of the hole inspection, the verticality is 30-150mm, which is far less than the allowa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com