Variable section hydraulic self-propelled trolley and operation method thereof

A technology of self-propelled platform and variable cross-section, which is applied in water conservancy projects, sea area projects, coastline protection, etc. It can solve the problems of inconsistent size of lining trolleys, large safety risks, and high hidden dangers, so as to ensure reliability, safety and security. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

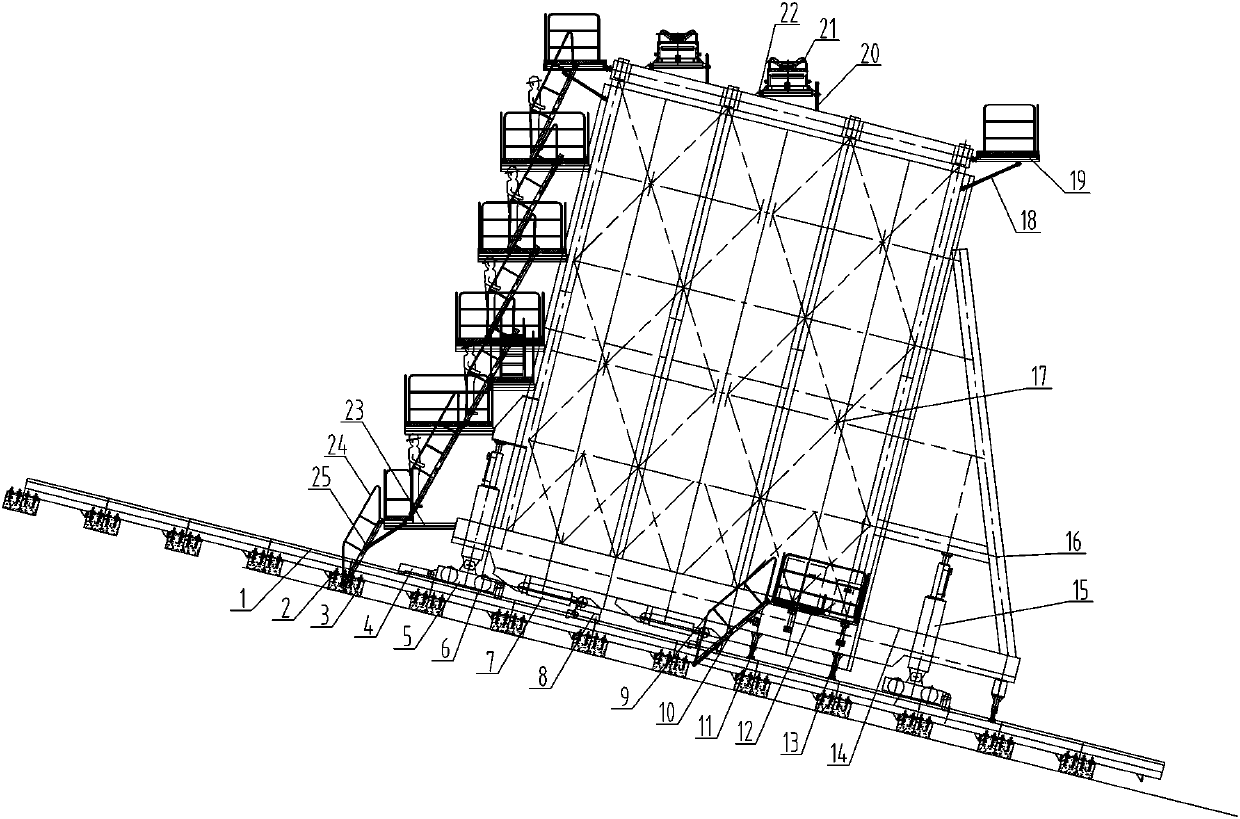

[0037] see Figure 1-2 , a variable-section hydraulic self-propelled trolley, which includes a trolley track 1 fixed on the lining floor, and a plurality of sets of track wheels 6 are installed on the top rolling support of the trolley track 1, and the track wheels 6 are fixedly mounted on the wheel On the support frame 5, a trolley frame 14 is installed on the wheel support frame 5 through a lifting mechanism, and a trolley power unit for trolley movement is installed on the bottom of the trolley frame 14, and the trolley frame The top of 14 is fixedly installed with a plurality of telescopic sleeves 30 across the top, and telescopic rods 29 are mounted on the inside of the telescopic sleeves 30 through sliding fit, and telescopic hydraulic cylinders 31 are installed between the telescopic sleeves 30 and the telescopic rods 29. , the outer end surface of the telescopic hydraulic cylinder 31 is fixedly installed with a template 26 for pouring, and a stripping hydraulic cylinde...

Embodiment 2

[0048] The operation method of any one of the variable-section hydraulic self-propelled trolleys for side wall lining construction includes the following steps:

[0049] Step 1: Support the entire trolley on the trolley track 1 through the track wheels 6;

[0050] Step 2: Adjust the height of the lifting hydraulic cylinder 15 according to the height of the tunnel, and then adjust the height of the trolley frame 14 to adapt to tunnels of different heights;

[0051] Step 3: Adjust the telescopic hydraulic cylinder 31 and the stripping hydraulic cylinder 27 according to the width of the tunnel, and then push the template 26 to move to the side wall to be poured, and then pour it;

[0052] Step 4: After the pouring of the side wall lining of this warehouse surface is completed, the film is removed, the power unit of the trolley is started, and the above-mentioned trolley is driven to move as a whole through the climbing hydraulic cylinder 7, and enters the next warehouse surface; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com