Heald frame connecting device of crank shedding loom

A connecting device and heald frame technology, which is applied in the direction of textile, heald, textile and paper making, etc., can solve problems such as the deflection of the upper connection of the heald frame connecting rod, poor connection of lifting lugs, shortened service life, etc., and achieve smooth running up and down, Good connection effect, creating high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

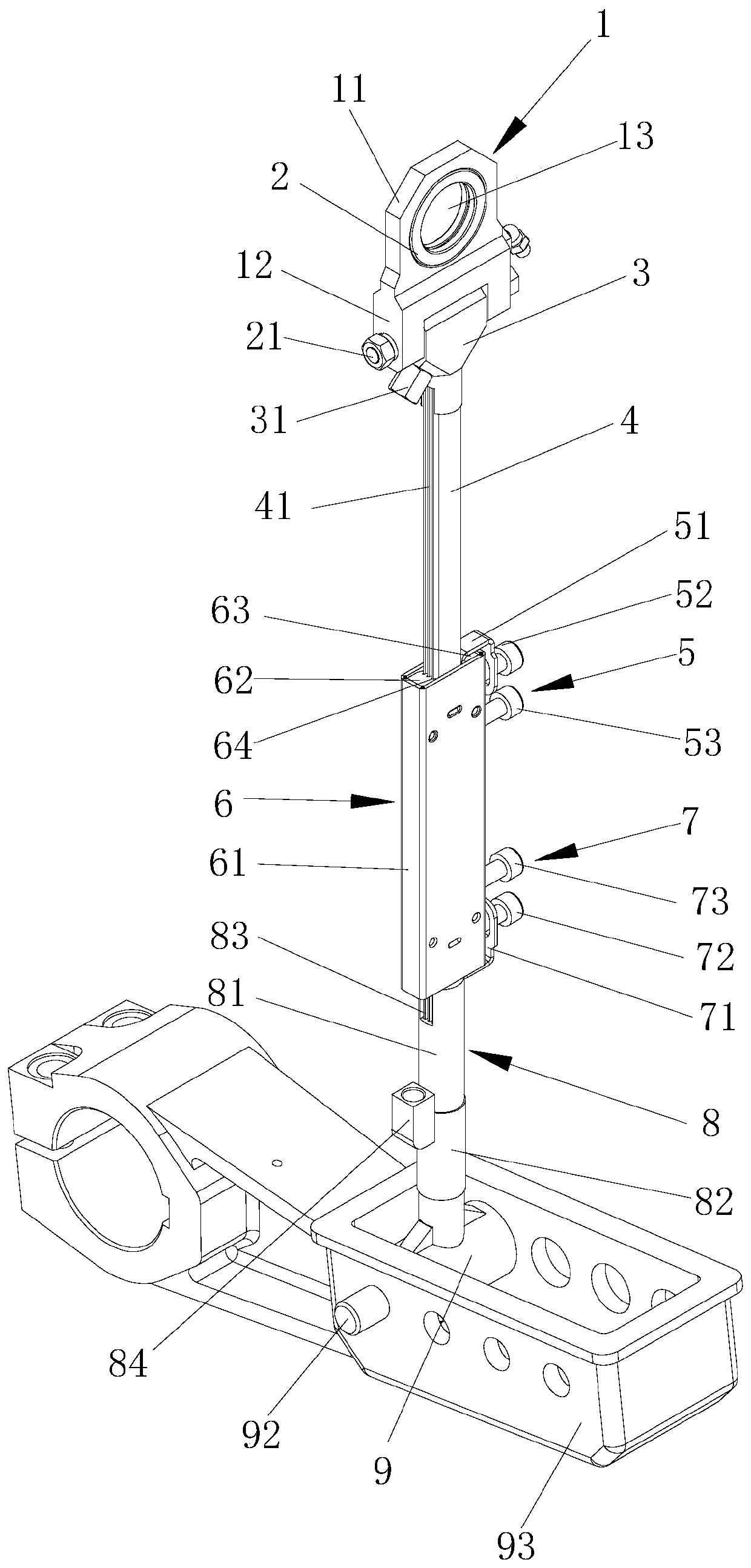

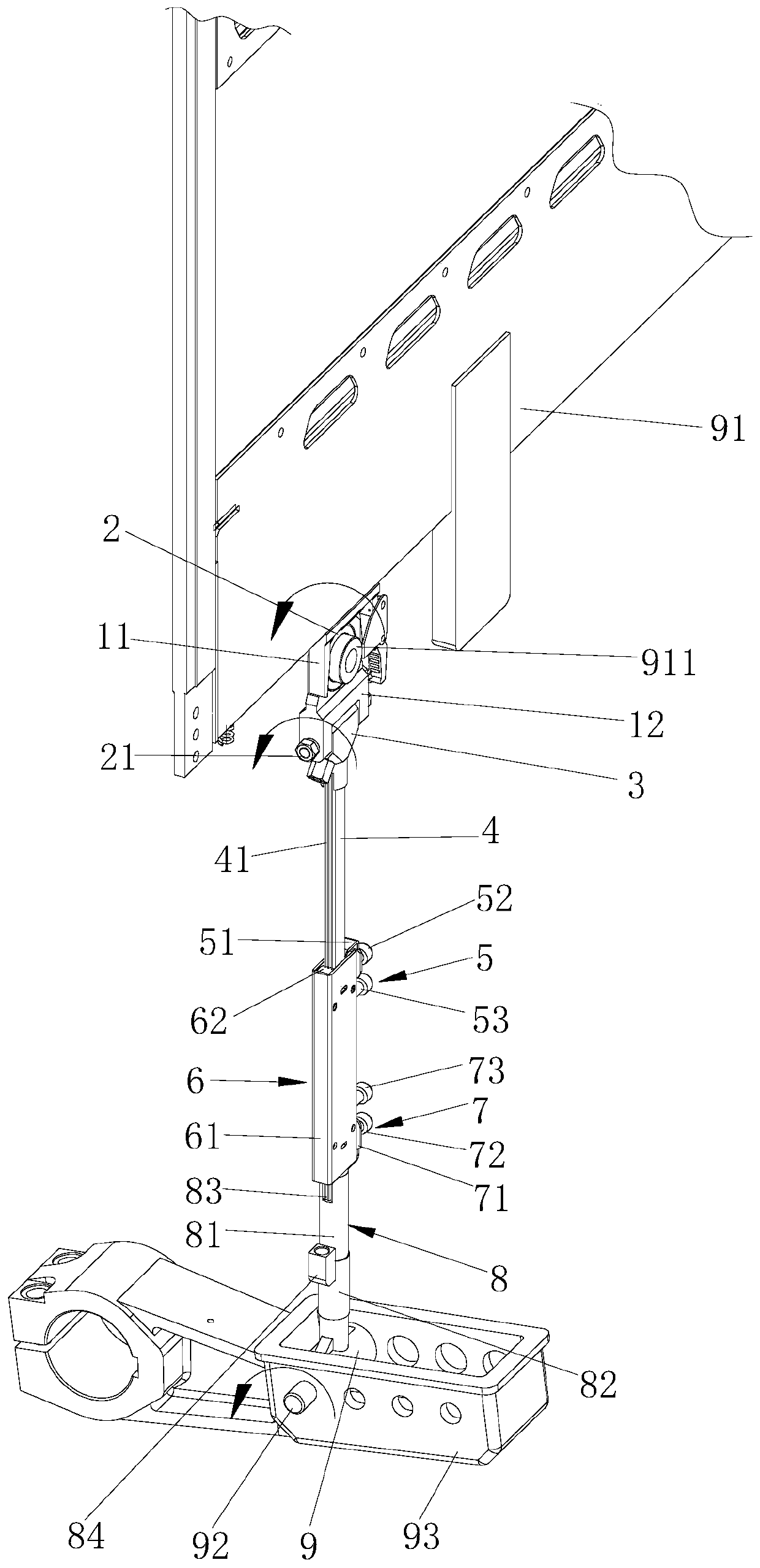

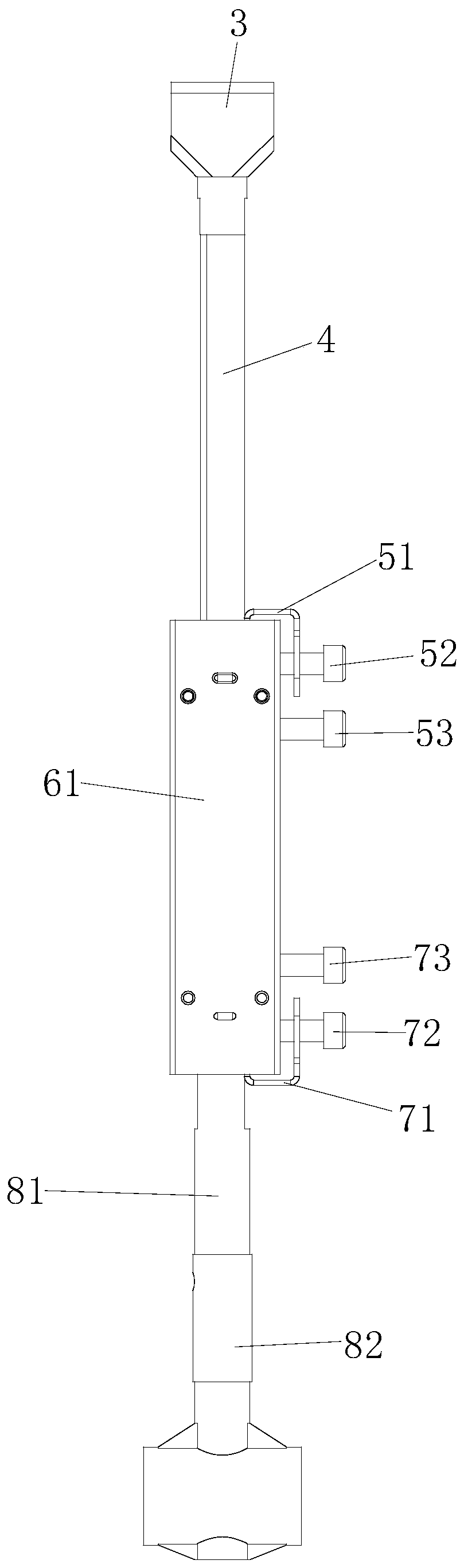

[0035] combine Figure 1 to Figure 4 , a crank opening loom heald frame connection device, comprising a first upper connection seat 1, a first connection bushing 2 is arranged inside the first upper connection seat 1, and the lower end of the first upper connection seat 1 passes through a first connection pin 21 Rotationally connected with the first upper rotating block 3, the lower end of the first upper rotating block 3 is connected with the first upper gear rod 4, and the lower end of the first upper gear rod 4 is movably connected with the first middle connection through the first pressing mechanism 5. Seat 6, the bottom of the first middle connecting seat 6 is connected with the first lower rack 8 through the second pressing mechanism 7, and the lower end of the first lower rack 8 is connected with the first lower connecting seat 9.

[0036] The first upper connecting seat 1 comprises the first upper square block 11 and the first lower U-shaped block 12, the first lower U...

Embodiment 2

[0051] When the above-mentioned heald frame connecting device of the open crank loom is used, it is used to connect the heald frame structure and the heald lifting foot structure on the loom. During the weaving operation of the loom, the first upper connecting seat 1 is fastened to the heald frame connecting shaft 911 of the J-shaped heald frame structure 91 through the first connecting bush 2 . The middle of the first upper connection seat 1 is provided with a first connection bushing 2 to avoid wear when the first upper connection seat 1 and the heald frame connection shaft 911 swing in the left and right directions, and improve the smoothness of rotation. When the crank loom runs up and down, the position of the heald frame can be adjusted in real time through the heald frame connecting device that can swing back and forth, so as to avoid wear and tear when the heald frame runs up and down. The first upper connecting base 1 is connected with the first upper rotating block 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com