Tea essence, and preparation method and application thereof

A technology of tea and essence, which is applied in the field of tobacco thermal reaction essence production, can solve the unsolved problems of cigarette tar reduction, harm reduction and flavoring, failure to meet consumer demand, loss of cigarette aroma components, etc., to achieve mellow and pleasant aroma, smoke Delicate and elegant, reduce the effect of poisonous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

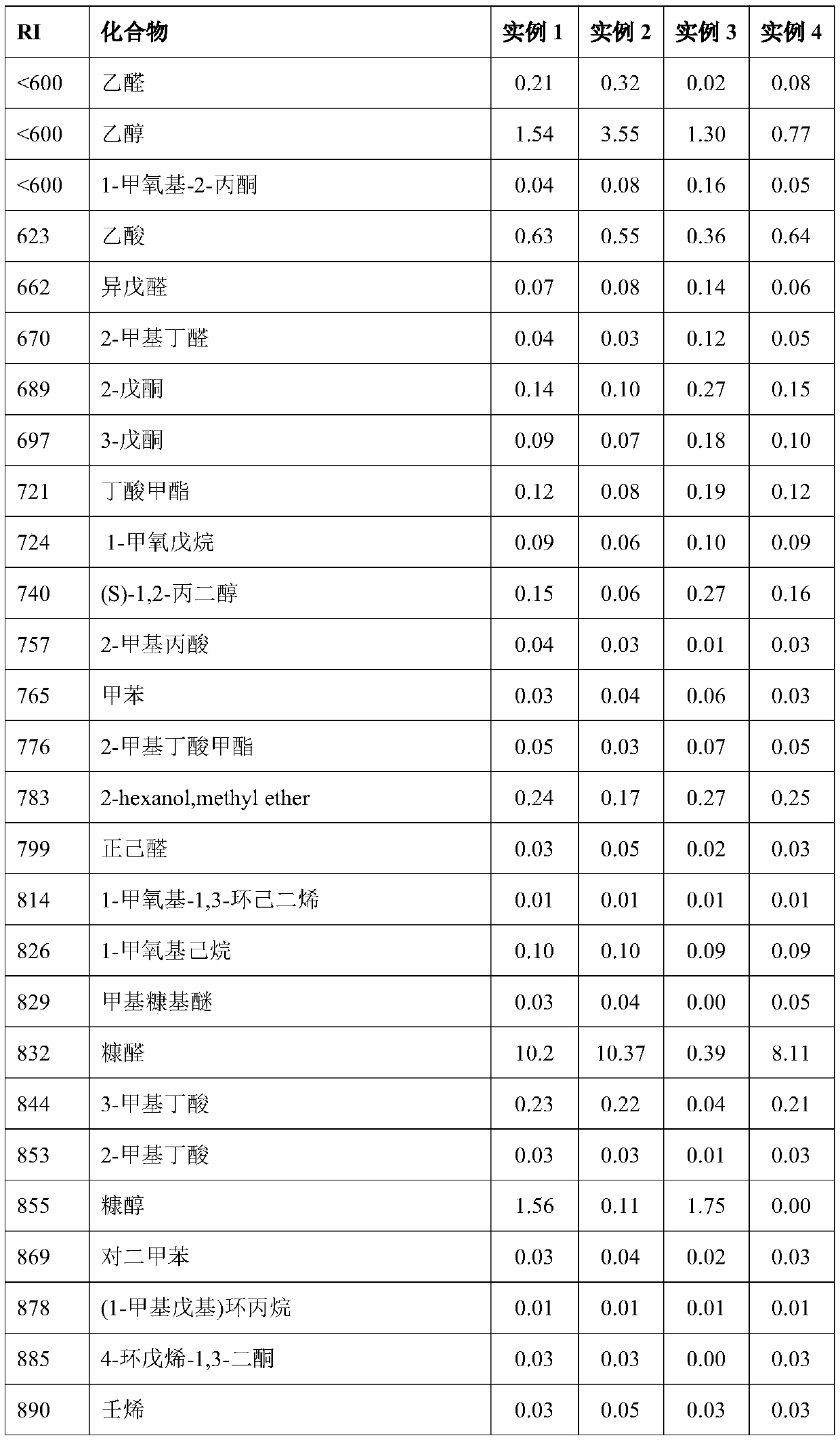

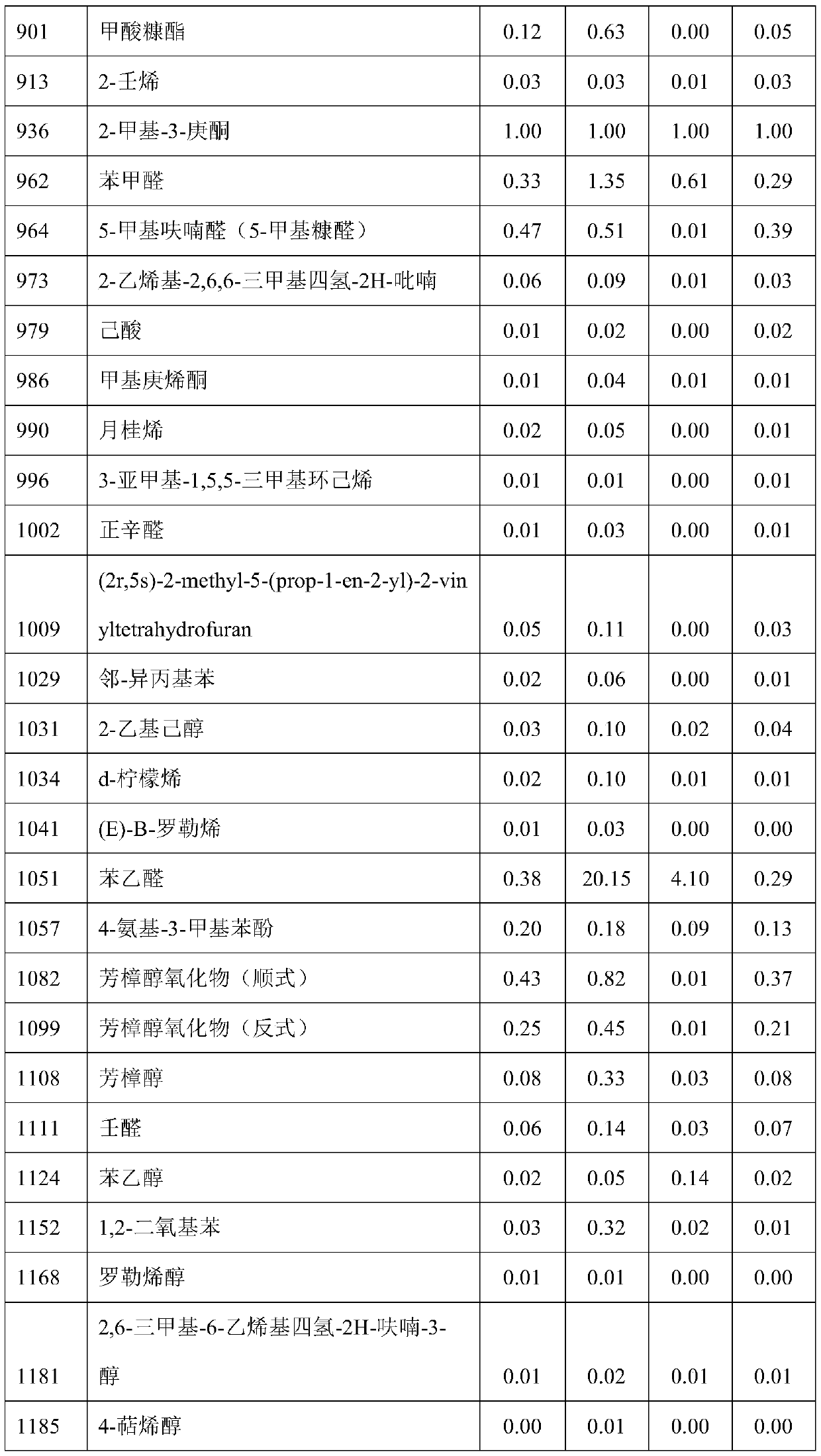

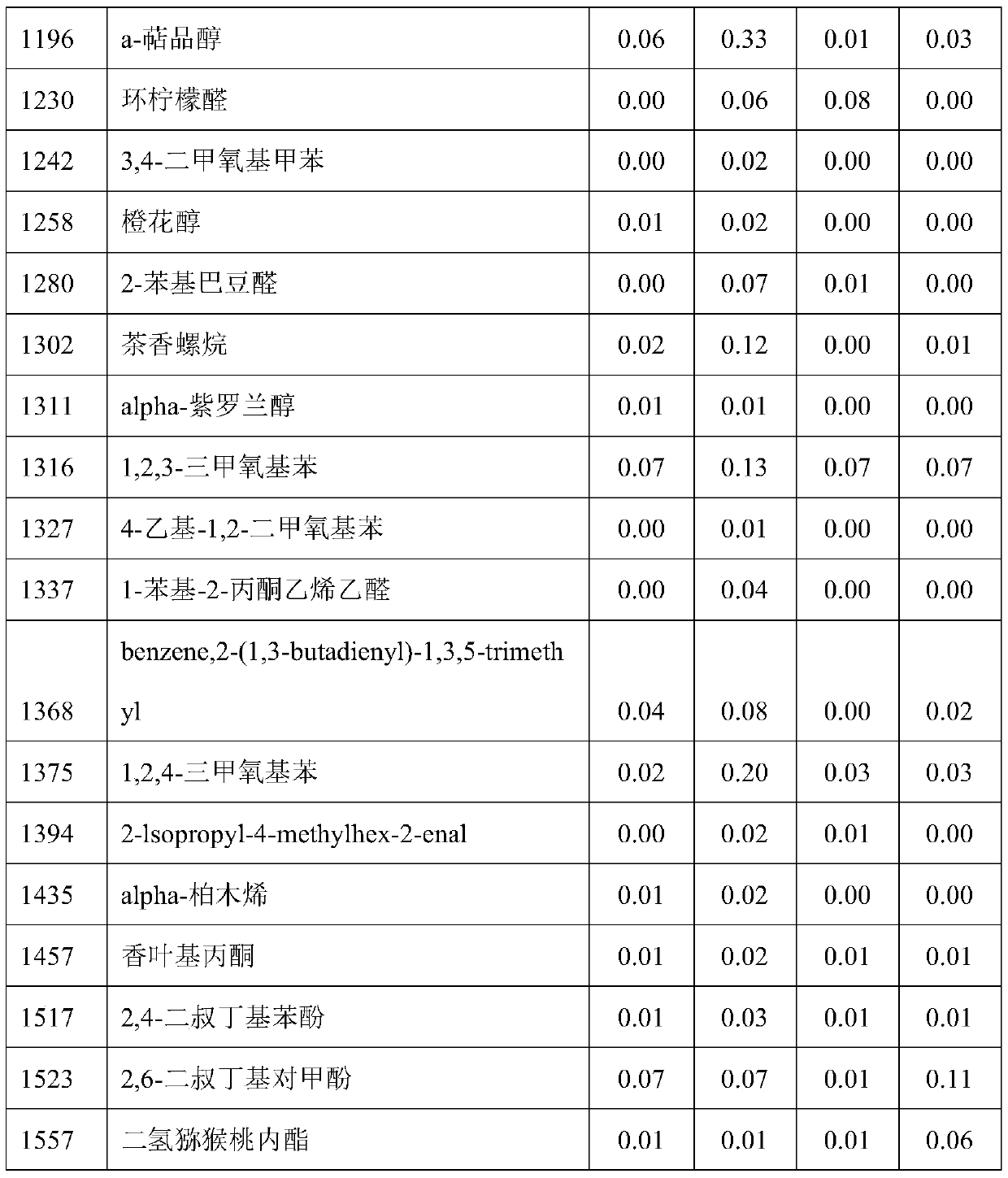

Examples

Embodiment 1

[0050] A preparation method of tea essence, comprising the following steps:

[0051] S1. Preparation of tea enzymatic solution: pass Dianhong crushed tea through an 80-mesh sieve, add 100 parts of tea powder and 1500 parts of water, mix well, adjust the pH to 5.0, add cellulase according to 2.5% of the mass of tea powder, and heat at 50°C Constant temperature water bath for 4 hours, adjust the pH to 8.0, add alkaline protease according to 1.5% of the tea powder mass, 50°C constant temperature water bath for 6 hours, to obtain tea powder enzymatic hydrolysis solution;

[0052] S2. Preparation of tea essence: take the enzymolysis solution and adjust the pH to 8, add aspartic acid at a mass ratio of 2% of the enzymolysis solution, and react with 0.3% fructose of the enzymolysis solution for 3 hours at 110° C. The Maillard reaction solution is cooled, centrifuged and filtered to obtain the tea essence.

Embodiment 2

[0054] A preparation method of tea essence, comprising the following steps:

[0055] S1. Preparation of tea enzymatic solution: crush Dianhong crushed tea, pass through a 40-mesh sieve, add 100 parts of tea powder and 1800 parts of water, mix well, adjust the pH to 5.5, add cellulase and 1.0% of the mass of tea powder Pectinase, in a constant temperature water bath at 45°C for 3 hours, adjust the pH to 8.0, add alkaline protease according to 1.0% of the mass of the tea powder, and bathe in a constant temperature water bath at 55°C for 3 hours, to obtain a tea powder enzymatic hydrolysis solution;

[0056] S2. Preparation of tea essence: get the enzymolysis solution, adjust to pH 9, add aspartic acid and phenylalanine at a mass ratio of 2% of the enzymolysis solution, the mass ratio of aspartic acid and phenylalanine is 20:1, add 0.2% xylose of enzymolysis solution quality, react at 110°C for 4 hours, cool the resulting Maillard reaction solution, centrifuge and filter to obtai...

Embodiment 3

[0058] A preparation method of tea essence, comprising the following steps:

[0059] S1. Preparation of tea enzymatic solution: pass Dianhong crushed tea through an 80-mesh sieve, add 100 parts of tea powder and 1200 parts of water, mix well, adjust the pH to 4.5, add cellulase and dextran according to 1.5% of the mass of tea powder Carbohydrase, in a constant temperature water bath at 50°C for 6 hours, adjust the pH to 8.0, add papain according to 2.5% of the mass of the tea powder, and bathe in a constant temperature water bath at 40°C for 4 hours to obtain a tea powder enzymatic hydrolysis solution;

[0060] S2. Take the enzymatic solution, adjust the pH to 8.5, add proline and phenylalanine according to the mass ratio of 1.5% of the enzymatic solution, and react with arabinose of 0.1% enzymatic solution mass at 110° C. for 3 hours, The obtained Maillard reaction solution is cooled, centrifuged and filtered to obtain the tea essence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com