Superhydrophobic deicing composite coating and preparation method thereof

A composite coating and hydrophobic coating technology, which is applied in the coating, metal material coating process, polyurea/polyurethane coating, etc., can solve the problems of increased heating power, increased heating time, and reduced stability of the heating coating. Achieve the effects of reducing power density, improving stability, and shortening heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

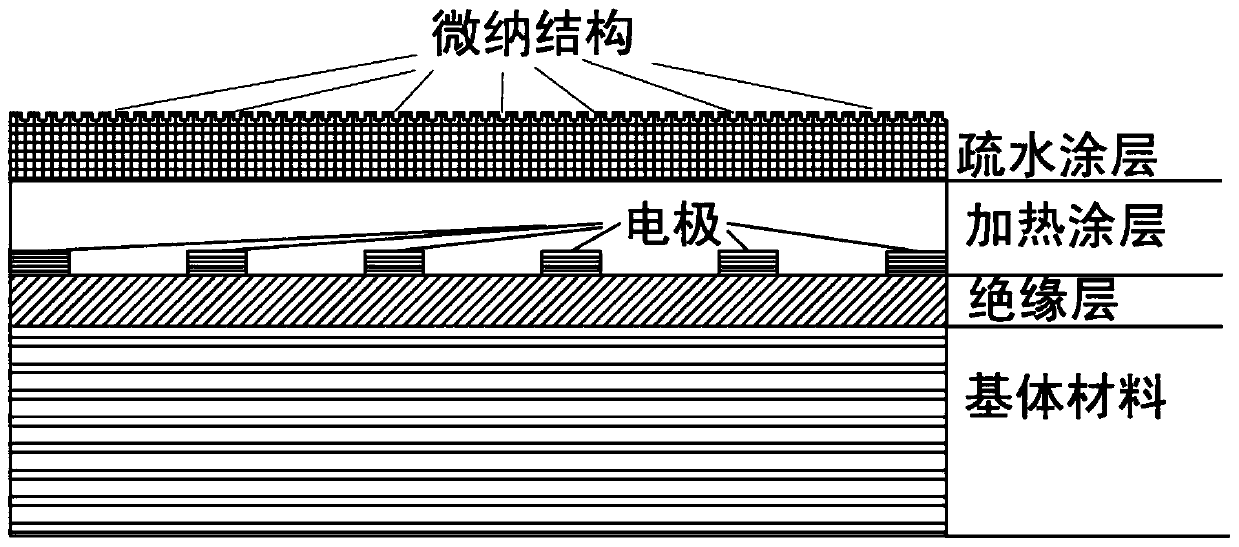

[0040] Example 1: (Ultrafast Laser Machining Heating / Hydrophobic Structured Coating)

[0041] based on figure 1 The schematic diagram of the multi-layer structure shown is sprayed by liquid pneumatic spray gun and ultra-fast laser processing. The process steps are as follows:

[0042] Step 1, preparation of the bottom insulating layer

[0043] First, put the parts to be processed into acetone solution, put them into the ultrasonic cleaning test machine for 30 minutes of ultrasonic cleaning, dry them with a hair dryer, put them in alcohol solution, put them into ultrasonic cleaning for 30 minutes, and finally dry them with a hair dryer.

[0044] Then, the base material is placed in the spraying workshop, and the non-conductive organic coating of polytetrafluoroethylene or polyurethane is used for spraying. In this embodiment, the polytetrafluoroethylene emulsion is used for vibration mixing for 5 minutes, and then the polytetrafluoroethylene emulsion is placed Enter the pneum...

example 2

[0057] Example 2: (Preparation of heating / hydrophobic structured coating by micro-imprinting)

[0058] based on figure 1 The schematic diagram of the multi-layer structure shown is sprayed by liquid pneumatic spray gun and ultra-fast laser processing. The process steps are as follows:

[0059] Step 1, preparation of the bottom insulating layer

[0060] First, put the parts to be processed into acetone solution, put them into the ultrasonic cleaning test machine for 30 minutes of ultrasonic cleaning, dry them with a hair dryer, put them in alcohol solution, put them into ultrasonic cleaning for 30 minutes, and finally dry them with a hair dryer.

[0061] Then, the base material is placed in the spraying workshop, and the non-conductive organic coating of polytetrafluoroethylene or polyurethane is used for spraying. In this embodiment, the polytetrafluoroethylene emulsion is used for vibration mixing for 5 minutes, and then the polytetrafluoroethylene emulsion is placed Enter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com