Method for co-producing alpha-ultra-high-strength gypsum and sodium chloride and ultra-high-strength gypsum

An ultra-high-strength, sodium chloride technology, applied in chemical instruments and methods, alkali metal chlorides, inorganic chemistry, etc., can solve the problems of high investment and production costs, limit industrial production, reduce economic benefits, etc., and achieve low production costs , Reduce capital investment, low equipment investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of atmospheric pressure saline solution method of the present invention co-produces the method for α-ultra-high-strength gypsum and sodium chloride comprising the following steps:

[0046] 1) Get the calcium chloride waste liquid that soda ash factory produces and the sodium sulfate solid of white carbon black industrial by-product, mix, the concentration of calcium chloride in the calcium chloride waste liquid is 0.7mol / L, the chlorine in the calcium chloride waste liquid The mass ratio of calcium chloride to sodium sulfate in solid sodium sulfate is 0.5:1, react for 1 hour at 40°C and a stirring speed of 70 r / min, and settle for 5 hours to obtain a dihydrate gypsum slurry;

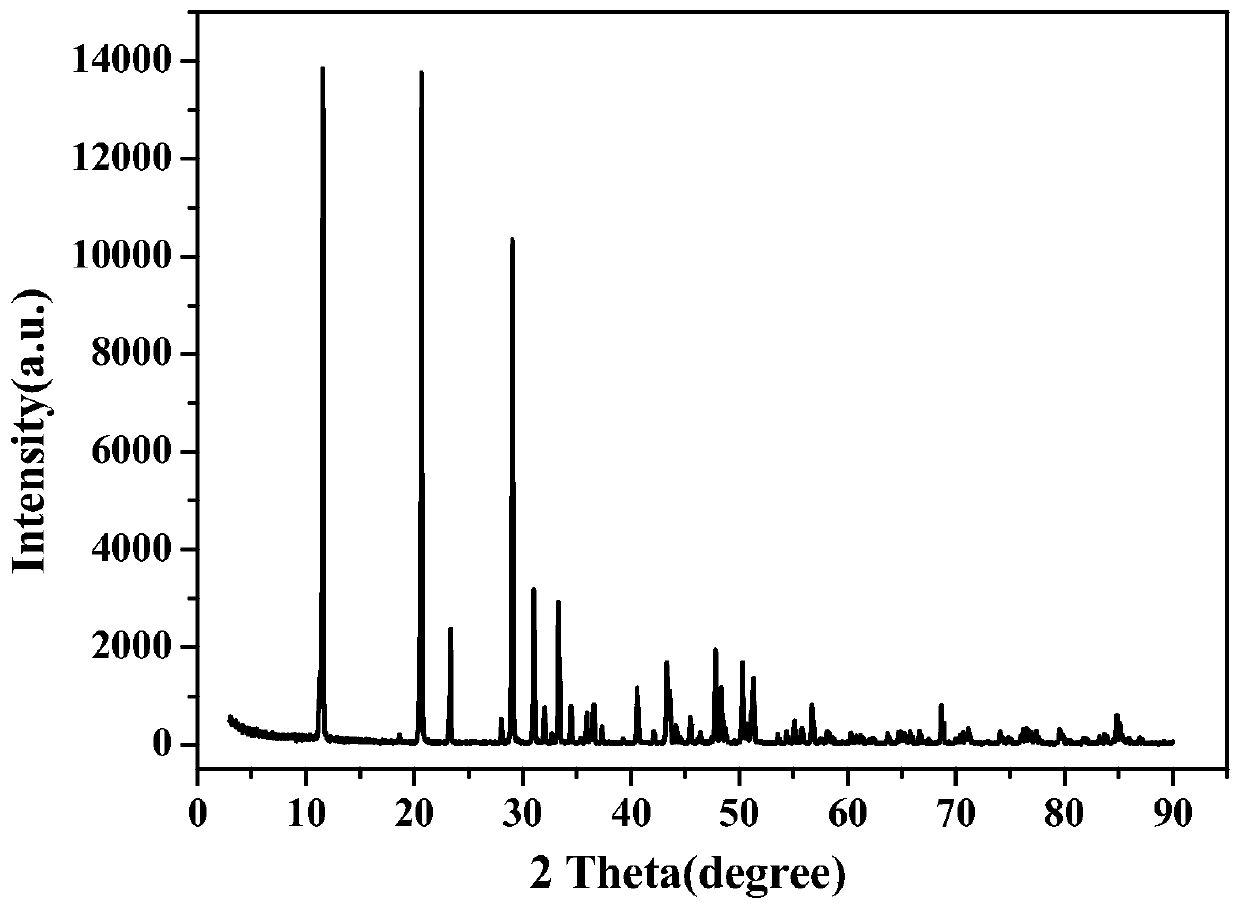

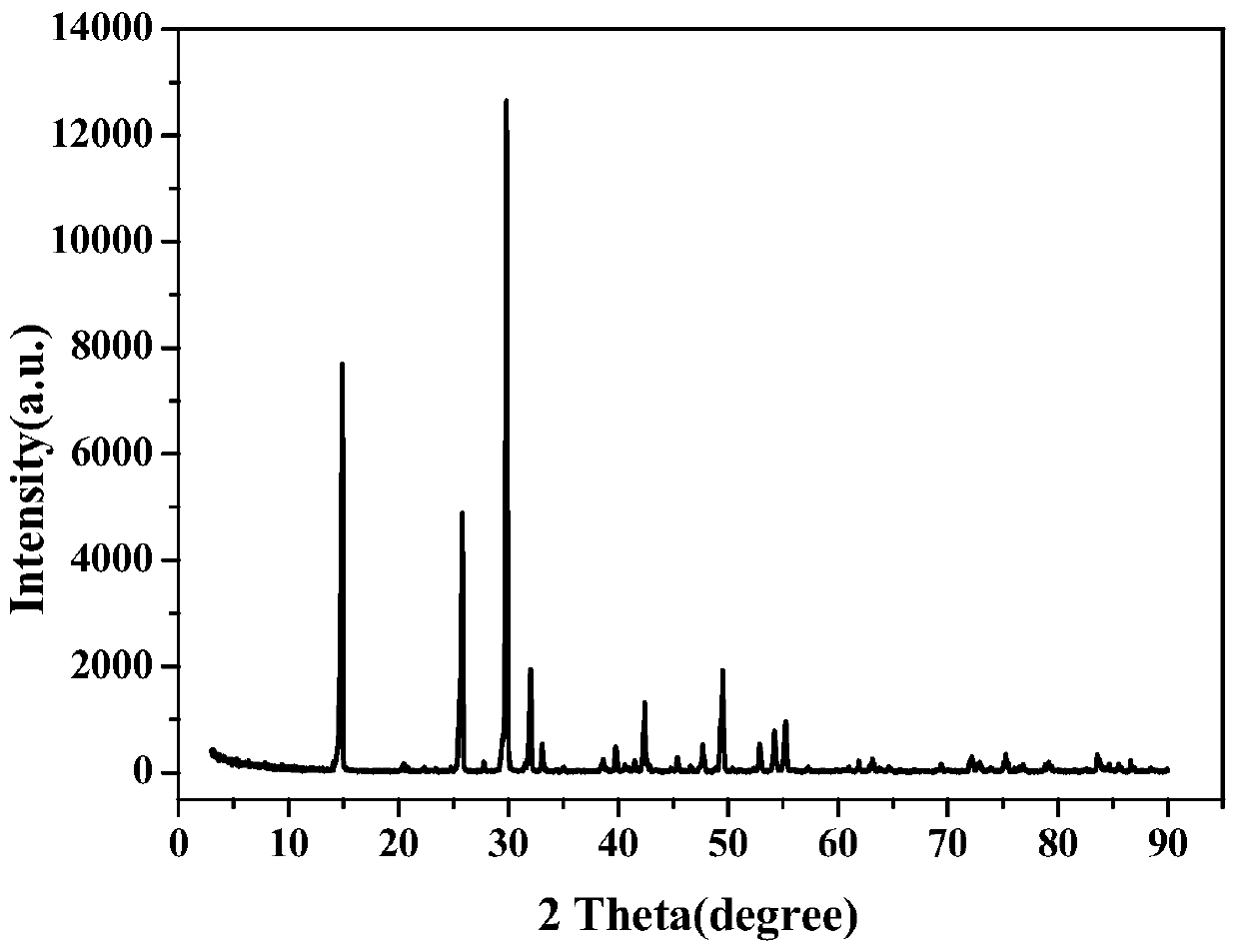

[0047]2) Separating the dihydrate gypsum slurry obtained in step 1) from solid to liquid to obtain a dihydrate gypsum crude product and a filtrate, the dihydrate gypsum crude product being plate-shaped dihydrate gypsum, washing the obtained dihydrate gypsum crude product to obtain dihydrate ...

Embodiment 2

[0051] A kind of atmospheric pressure saline solution method of the present invention co-produces the method for α-ultra-high-strength gypsum and sodium chloride comprising the following steps:

[0052] 1) Get the calcium chloride waste liquid that soda ash plant produces and the sodium sulfate solid of white carbon black industrial by-product and add respectively in the reaction crystallization kettle, mix, the concentration of calcium chloride in the calcium chloride waste liquid is 1.0mol / L, The substance ratio of calcium chloride in the calcium chloride waste liquid to sodium sulfate in the sodium sulfate solid is 1:1, react for 5 hours at 60°C and a stirring rate of 100 r / min, and settle for 20 hours to obtain a dihydrate gypsum slurry;

[0053] 2) Separating the dihydrate gypsum slurry obtained in step 1) from solid to liquid to obtain a dihydrate gypsum crude product and a filtrate, the dihydrate gypsum crude product being plate-shaped dihydrate gypsum, washing the obtai...

Embodiment 3

[0057] A kind of atmospheric pressure saline solution method of the present invention co-produces the method for α-ultra-high-strength gypsum and sodium chloride comprising the following steps:

[0058] 1) Take the calcium chloride waste liquid produced by the ammonia-soda method soda ash plant and the sodium sulfate solid produced by the white carbon black industry and add them to the reaction crystallization kettle respectively, mix, and the concentration of calcium chloride in the calcium chloride waste liquid is 0.8mol / L, the mass ratio of calcium chloride in calcium chloride waste liquid to sodium sulfate in sodium sulfate solid is 1:1.2, at 50°C and a stirring speed of 80r / min, react for 3h, settle for 10h, and get dihydrate gypsum slurry;

[0059] 2) Separating the dihydrate gypsum slurry obtained in step 1) from solid to liquid to obtain a dihydrate gypsum crude product and a filtrate, the dihydrate gypsum crude product being plate-shaped dihydrate gypsum, washing the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com