Machining machine tool for spiral bevel gears

A technology for spiral bevel gears and machine tools, which is applied to gear cutting machines, metal processing equipment, gear tooth manufacturing devices, etc., can solve the problems of complex overall structure and complicated adjustment of machine tools, achieve simple overall structure, realize synchronous processing, and reduce quantity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

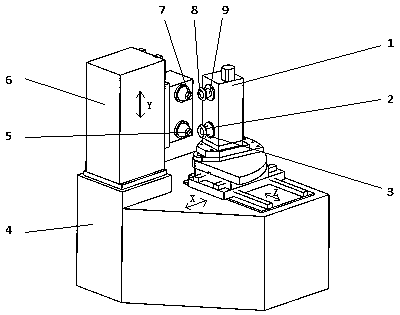

[0034] The spiral bevel gear processing machine tool in Embodiment 1 can process two spiral bevel gears at the same time, at this time, M=N=2.

[0035] like Figure 1-4 As shown, the spiral bevel gear processing machine tool includes a workpiece box 1 and a tool box 13, and the two are used together to realize the machining of the spiral bevel gear. The machine tool can be a gear milling machine or a gear grinding machine, and different types of Machined cutterhead.

[0036] Specifically, in the workpiece box 1, there are two workpiece spindles arranged in parallel and extending in parallel to install the workpiece. The workpiece is a spiral bevel gear, and the axes of the two workpiece spindles are parallel to each other. A workpiece motor 20, the workpiece motor 20 drives two workpiece spindles to rotate synchronously through a worm gear transmission mechanism.

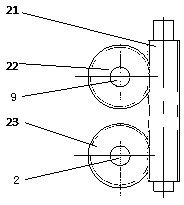

[0037] The worm and worm gear mechanism includes a worm 21, a first worm 23 and a second worm 22. The workpiece m...

Embodiment 2

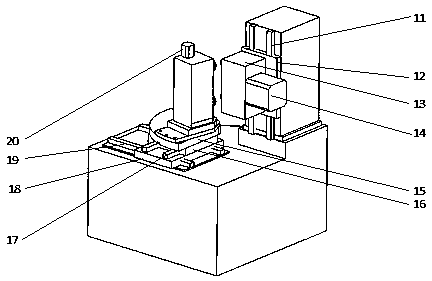

[0045] The spiral bevel gear processing machine tool in Embodiment 2 can process three spiral bevel gears at the same time, at this time, M=N=3. In the spiral bevel gear processing machine tool in Embodiment 2, only the structures of the workpiece box and the tool box are different from those in Embodiment 1, and the other structures of the machine tool are the same.

[0046] like Figure 5-6 As shown, the tool box is provided with three tool spindles arranged in parallel extending in parallel for installing machining tools. The axes of the three tool spindles are parallel to each other. A tool motor 14 is fixed on the tool box 13. The tool The motor drives the three tool spindles to rotate synchronously through the synchronous belt transmission mechanism.

[0047] The synchronous belt transmission mechanism comprises the driving pulley 28 that is connected with the cutter motor 14 transmission, and the first driven pulley 30, the second driven pulley 31, the 3rd driven belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com