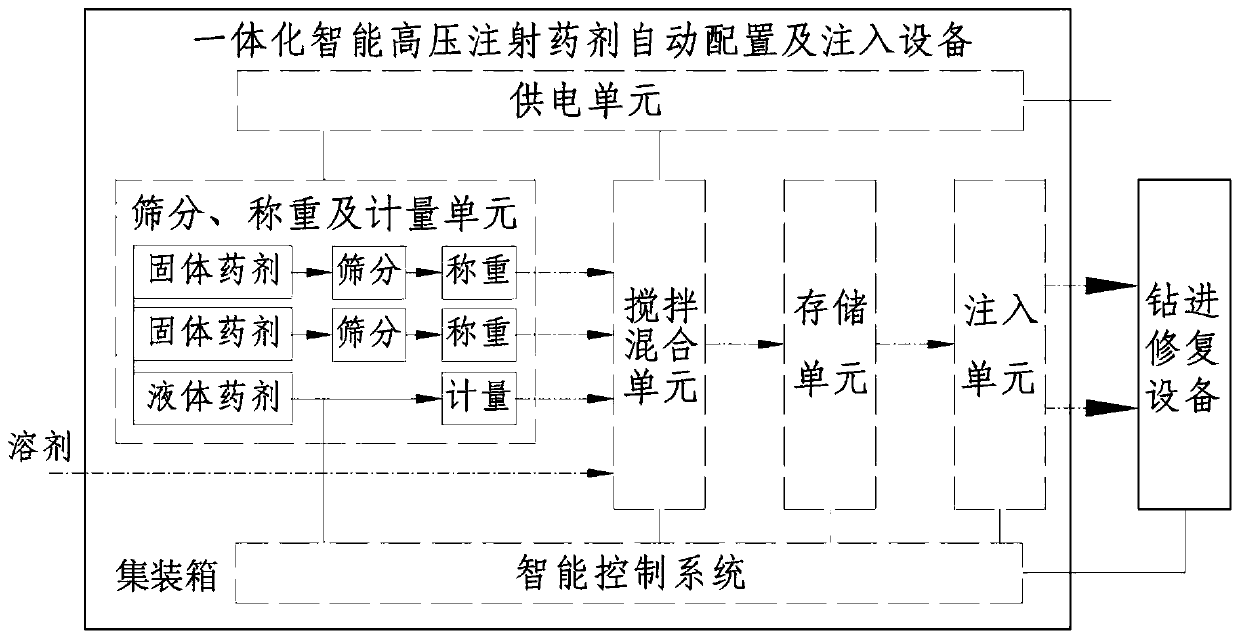

Integrated intelligent high-pressure injecting liquid medicine automatic dispensing and injecting device

A technology for high-pressure injection and injection equipment, which is applied in the direction of measuring devices, electric controllers, chemical instruments and methods, etc. It can solve the problems of rough liquid medicine addition and delivery process, difficult pressure control, single function, etc., and achieve a good user terminal interface , easy to transport and use, and highly intelligent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

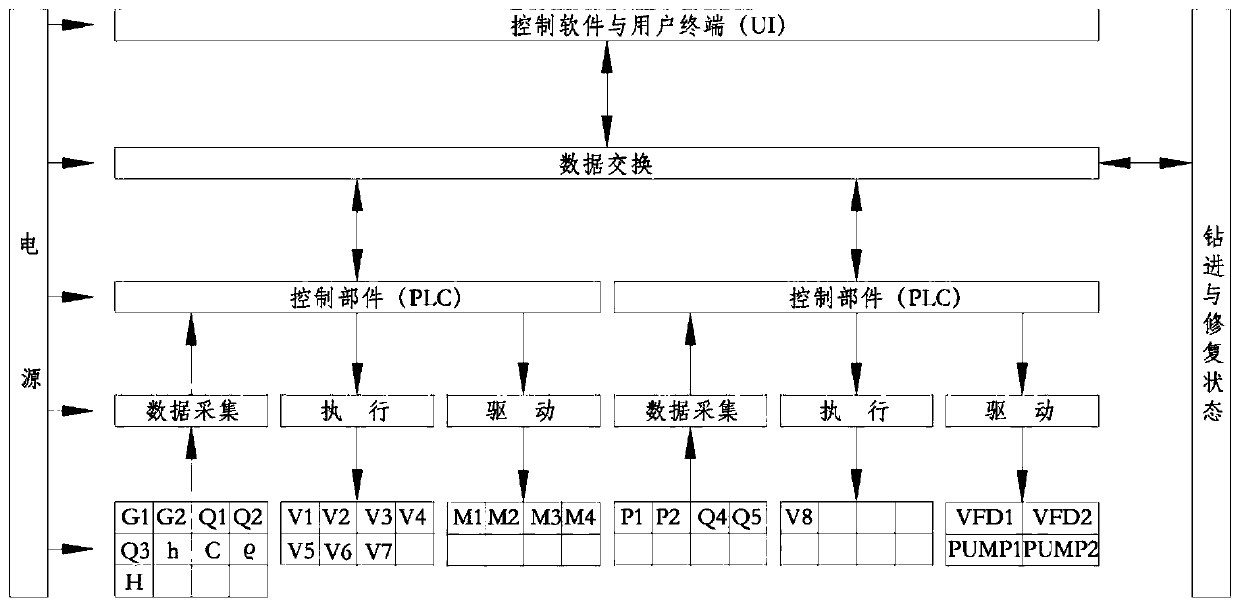

Method used

Image

Examples

Embodiment 1

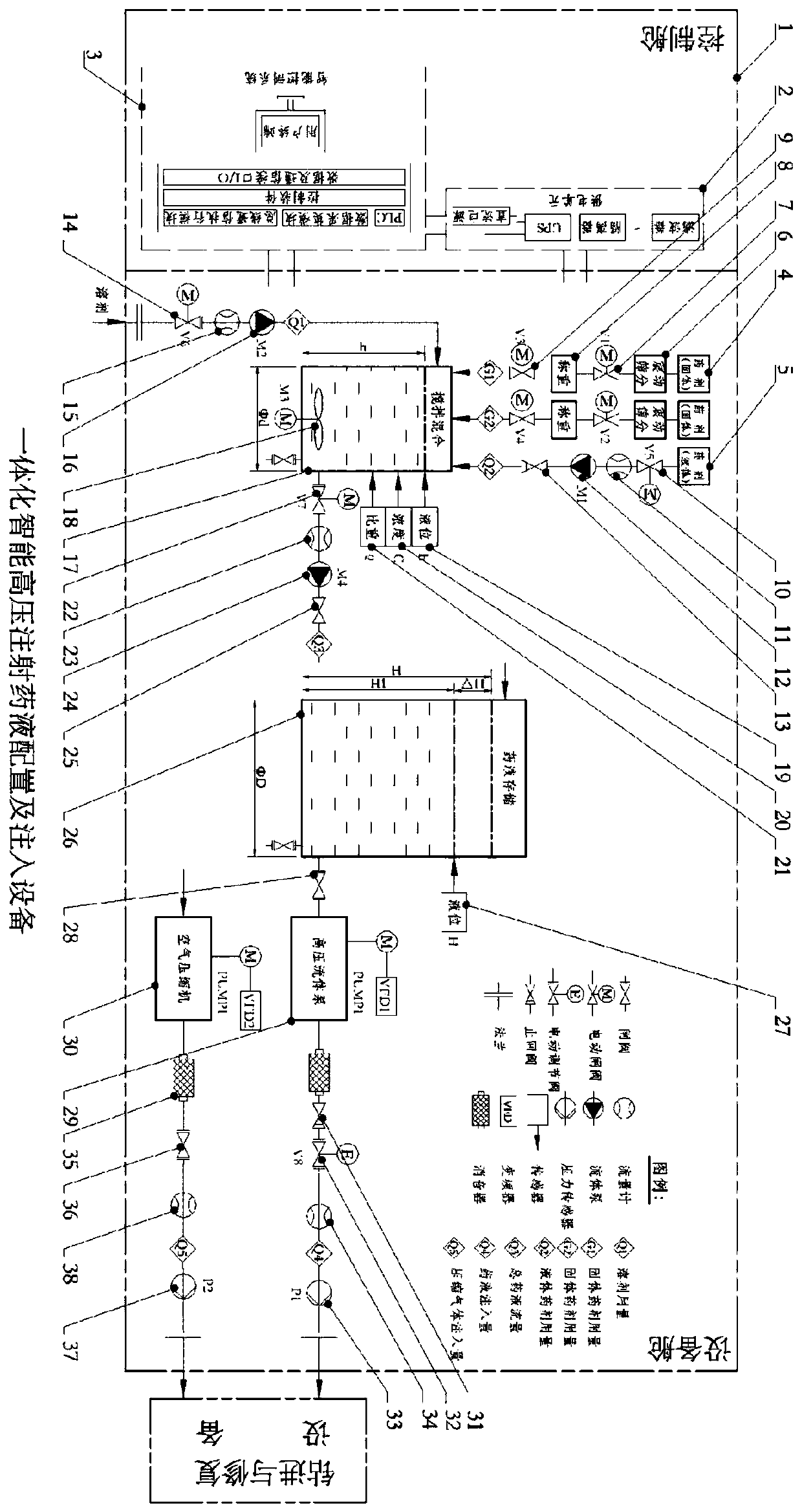

[0040] Example 1: Remediation of in situ polluted soil and groundwater using the shaft restoration process.

[0041] When using high-pressure injection technology for in-situ restoration of contaminated sites and groundwater, vertical well restoration, horizontal well restoration, and composite well restoration methods combining vertical and horizontal wells can be used as needed.

[0042] When the pollutants are distributed in a point shape, the shaft repair process can be used for repair. Use drilling equipment to drill vertically at the pollution distribution point, establish a vertical injection well, and inject the remediation liquid into the contaminated area to achieve the remediation goal. First of all, use the vehicle to transport the equipment to the site and hoist it to the repair site, connect the equipment with the drilling and repair equipment liquid and compressed air delivery pipelines, connect the equipment solvent delivery pipelines, connect the electrical in...

Embodiment 2

[0043] Example 2: Remediation of in-situ contaminated soil and groundwater using horizontal well remediation technology.

[0044] When the pollutants are distributed in flakes and the soil formation is sandy, the horizontal well restoration process can be used for restoration. The length of a single horizontal well can reach about 120m, and the repair range of a single well is large, and the repair efficiency is extremely high. When repairing, use drilling equipment to drill obliquely (deflection) at the pollution distribution point, then drill horizontally, establish a horizontal injection well, and inject the repairing liquid into the contaminated area to achieve the repairing goal. The remediation process is similar to Example 1, and the injection flow rate can be determined according to the distribution of pollution. The horizontal well remediation process is as follows: Figure 7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com