A wet-process resource utilization system for domestic waste incineration power plant slag

A technology for domestic waste incineration and recycling, which is applied in the field of domestic waste incineration power generation furnace slag wet recycling system, and can solve the problem of low brick strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with embodiment, but is not limited to the content on the description.

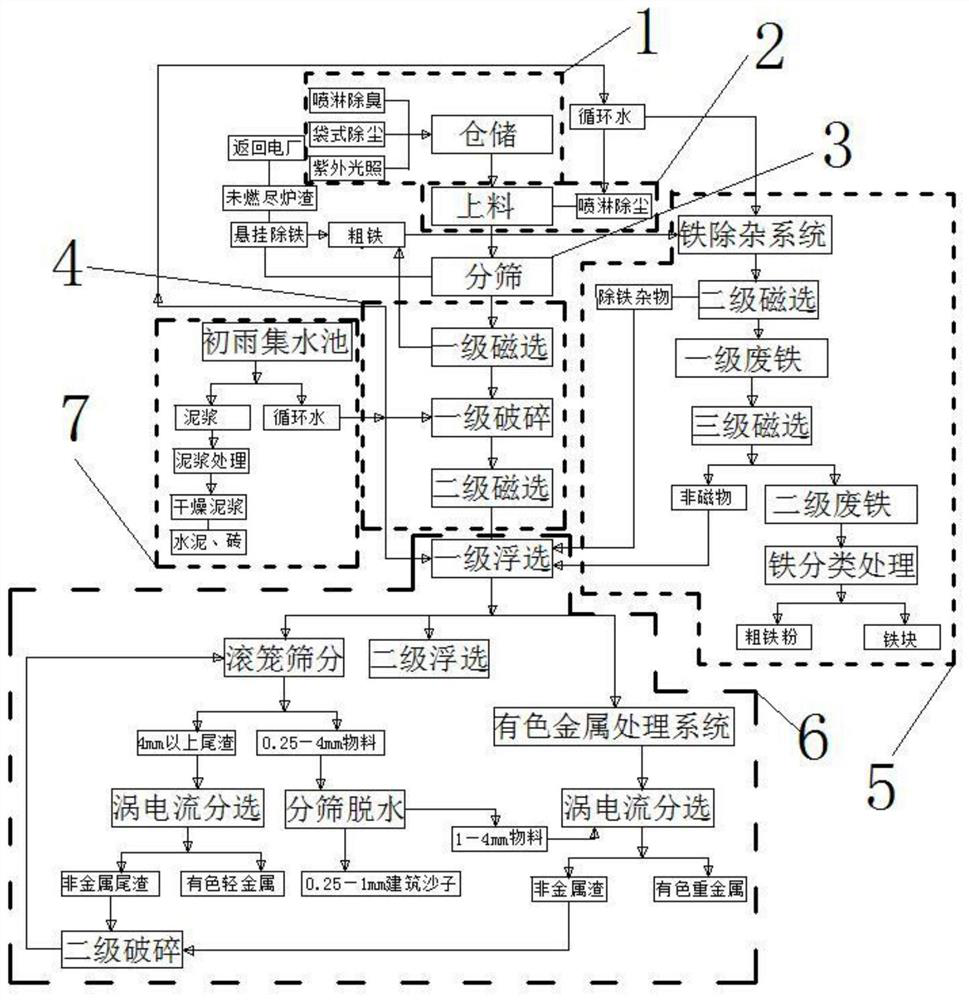

[0032] As shown in the figure: a domestic waste incineration power generation furnace slag wet resource utilization system, which includes a slag storage system 1, a slag feeding system 2, a slag sorting system 3, a slag magnetic separation system 4, an iron treatment system 5, a Magnetic metal treatment system 6, sewage treatment system 7.

[0033] The slag storage system 1 is the slag storage area. The slag is transported to the slag storage area by vehicles. The slag storage area includes the storage area and the spray deodorization system, ultraviolet light system and bag dust removal system installed in the storage area;

[0034] Spray deodorization system: Spray aromatic deodorant in the storage area to neutralize the odor of slag and adjust the moisture content of slag.

[0035] Ultraviolet light system: irradiate with ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com