Device for preparing epitaxial silicon wafer and purity detection method for silicon source material

A silicon source and silicon wafer technology, applied in sampling devices, analytical materials, measuring devices, etc., can solve the problem of not having the ability to detect silicon source materials, and achieve the effects of simple device, pollution avoidance, and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 3

[0058] Incoming material quality detection of embodiment 1 trichlorosilane

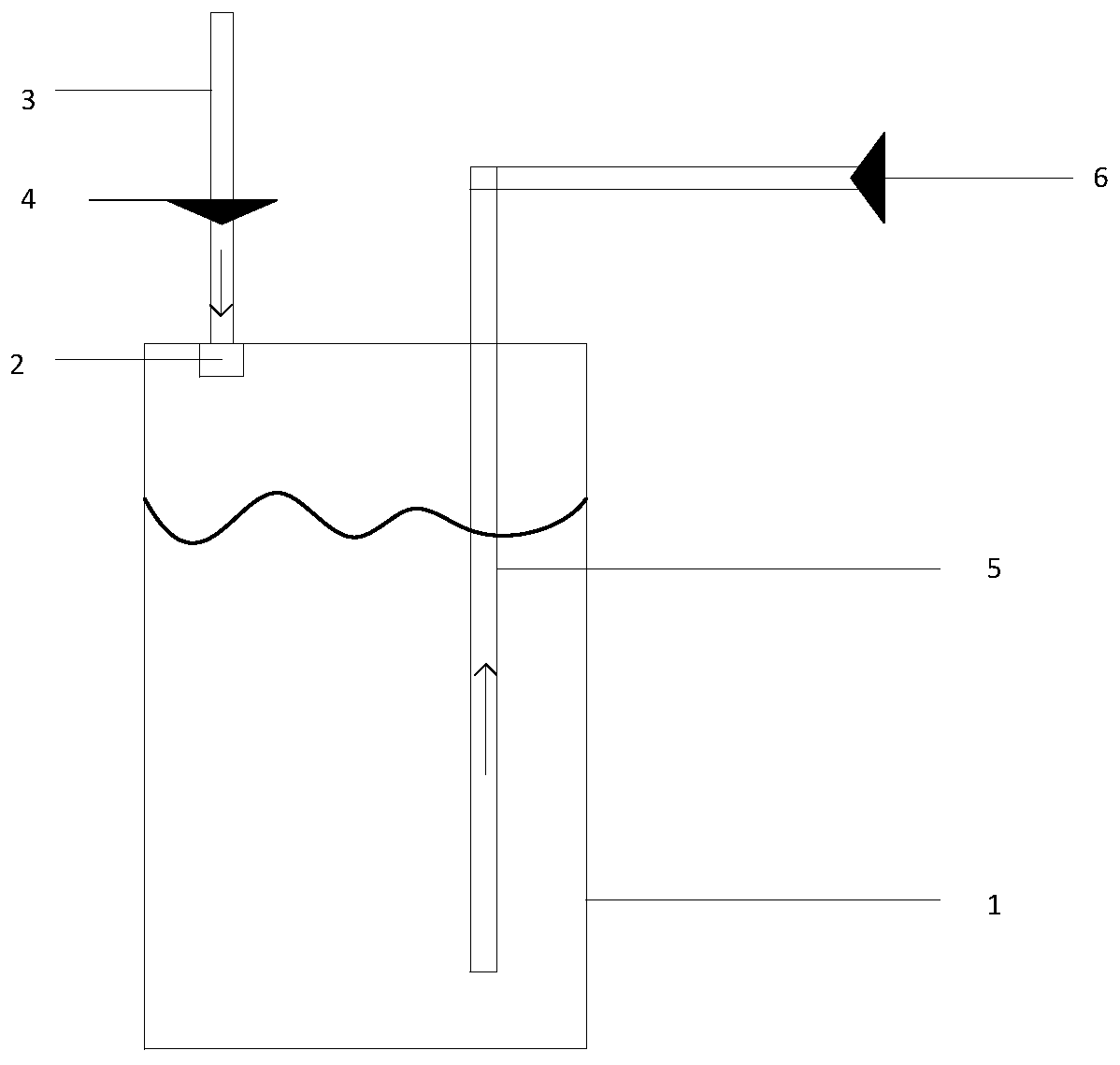

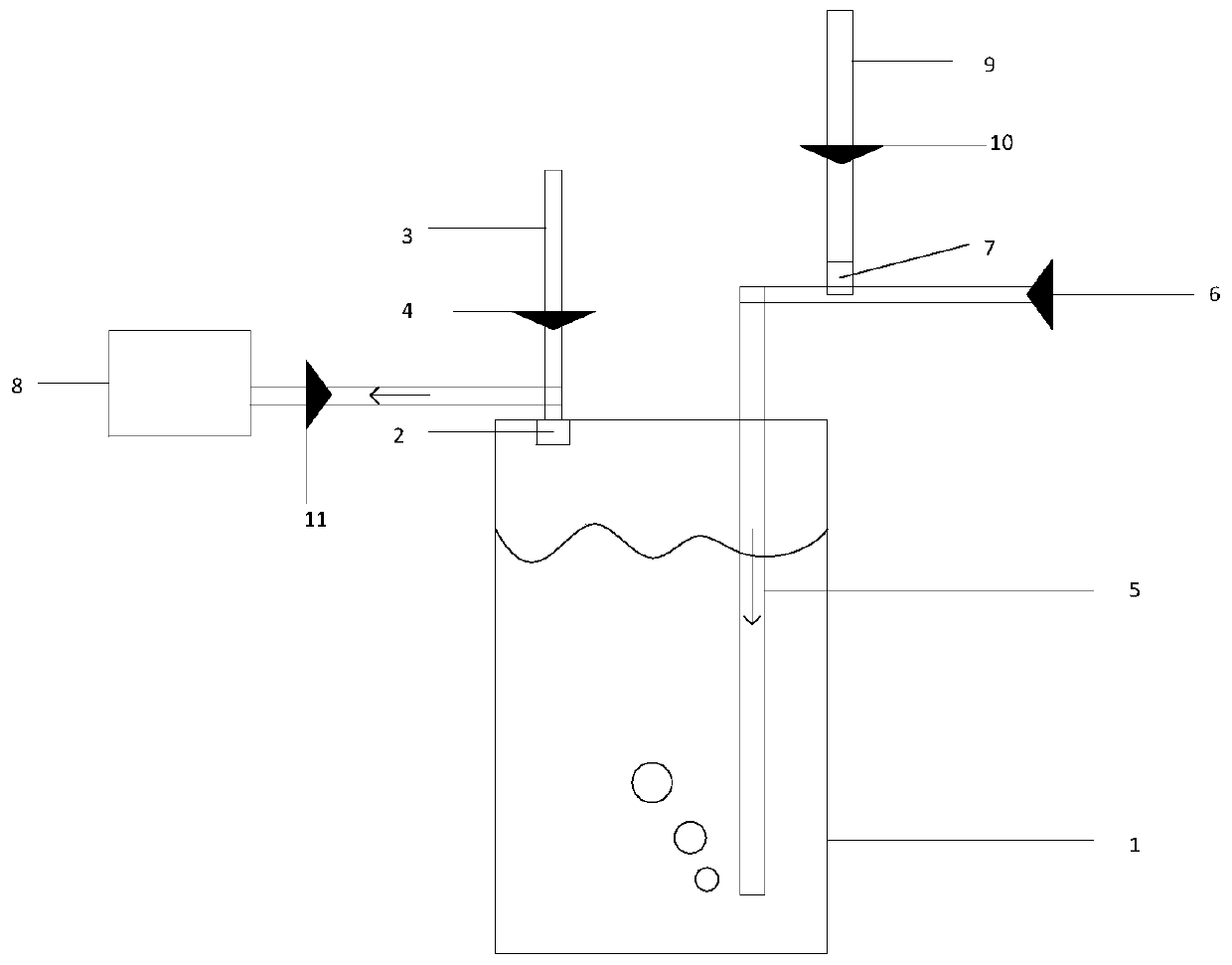

[0059] Before the preparation of epitaxial silicon wafers, the use of image 3 The device detects the purity of the purchased trichlorosilane.

[0060] Turn off the first switch and the second switch, and turn on the third switch and the fourth switch for detection. Hydrogen is transported from the second gas inlet to below the raw material liquid level of the trichlorosilane storage bottle, and a mixed vapor of trichlorosilane and hydrogen is formed in the space above the raw material liquid level. With the continuous introduction of hydrogen, the liquid level in the storage bottle The pressure in the above space increases, and the pressure serves as the driving force for transport, and the mixed vapor of trichlorosilane and hydrogen is diffused through the first gas inlet and transported to the chemical vapor deposition equipment.

[0061] The mixed steam reaches the chemical vapor deposition equi...

Embodiment 2 3

[0066] Embodiment 2 trichlorosilane gas sampling

[0067] For factories without testing conditions, this method can be used to take samples and send them to institutions with testing qualifications to complete the quality analysis of trichlorosilane.

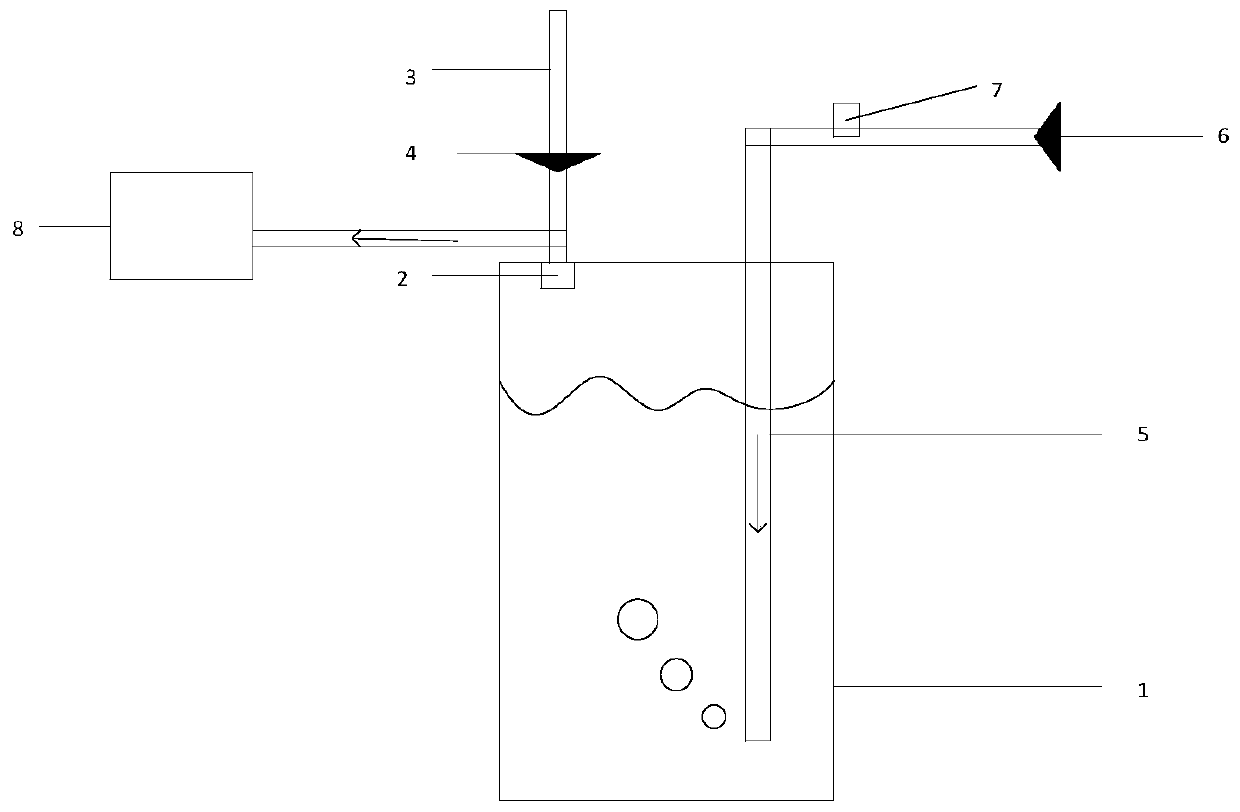

[0068] use Figure 4 The device shown, samples trichlorosilane gas.

[0069] Turn off the first switch and the second switch, and turn on the third switch and the fourth switch for detection. Hydrogen is transported from the gas inlet of the second hydrogen inlet to below the raw material liquid level of the trichlorosilane storage bottle, and a mixed vapor of trichlorosilane and hydrogen is formed in the space above the raw material liquid level. With the continuous introduction of hydrogen, the hydrogen in the storage bottle The pressure in the space above the liquid surface increases, and the pressure acts as the driving force for the transportation, and the mixed vapor of trichlorosilane and hydrogen is diffused through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com