Waste animal and vegetable fat hydrogenation product composition analysis method

A hydrogenation technology for discarded animals, plants, and oils, which is applied to the analysis of materials, material separation, and instruments. It can solve the problems of high instrument cost, influence on analysis results, and complex processing, and achieve cheap instruments, simple data processing methods, and efficient analysis. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

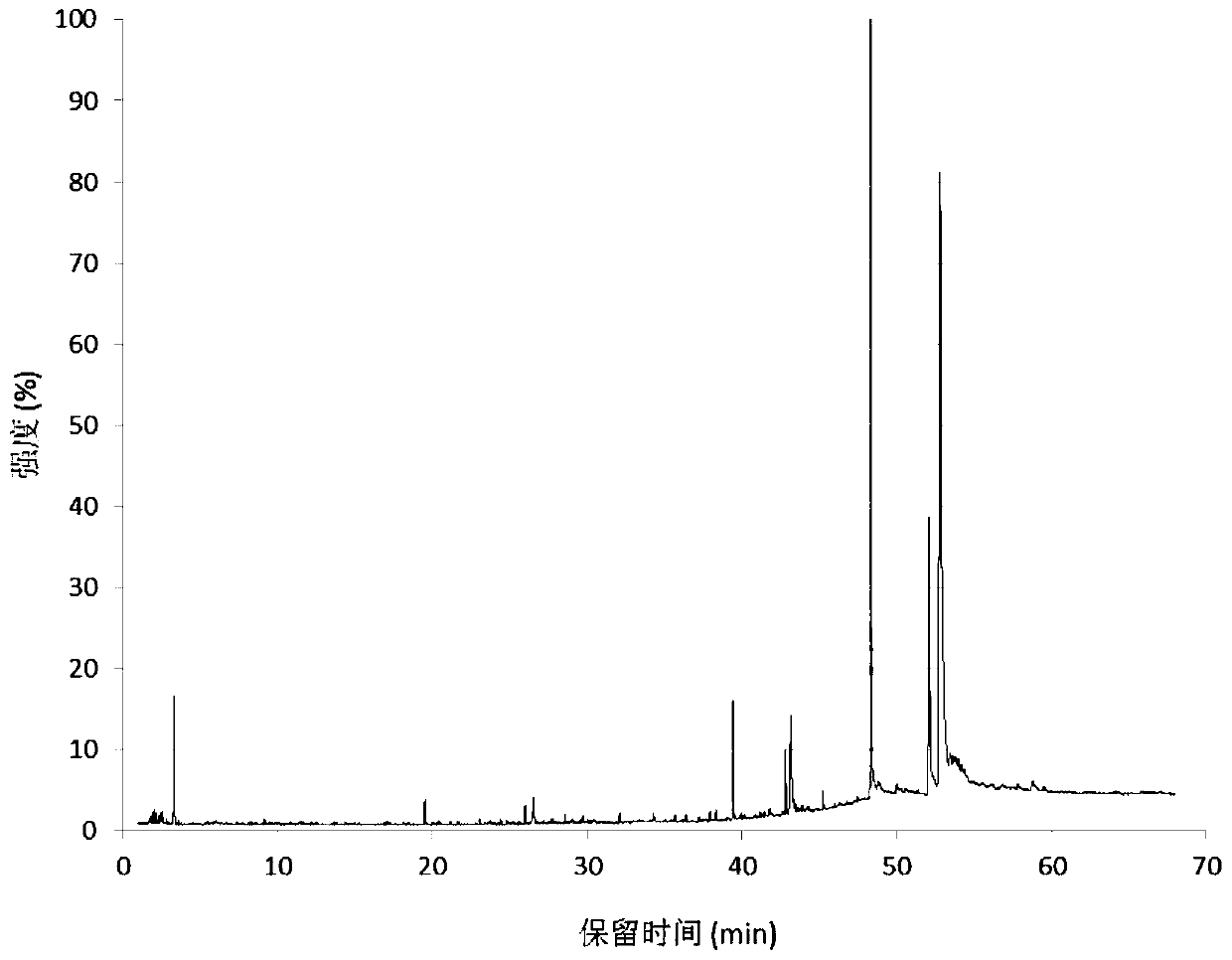

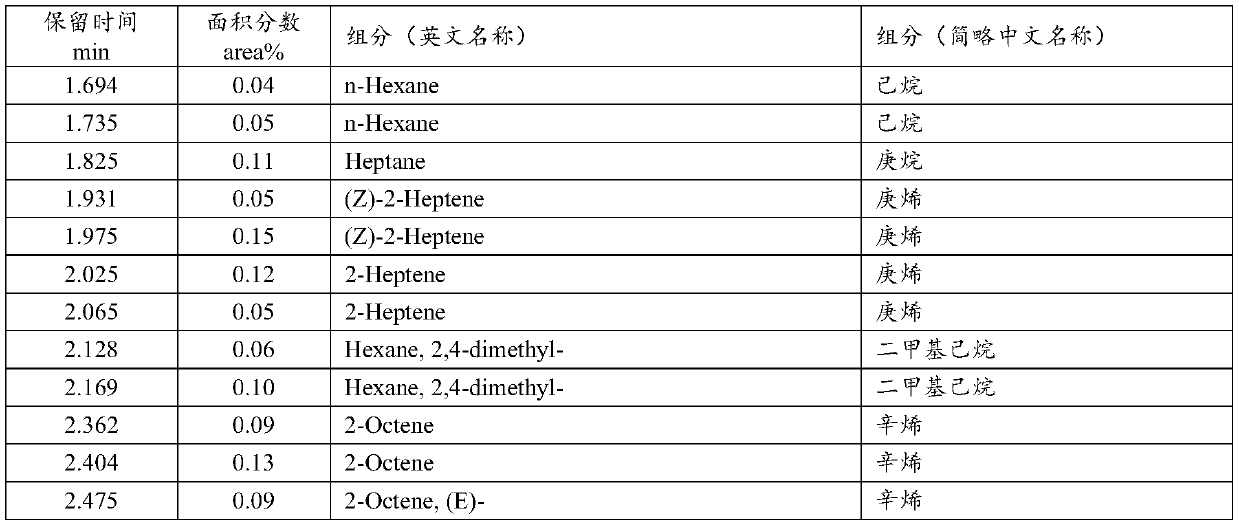

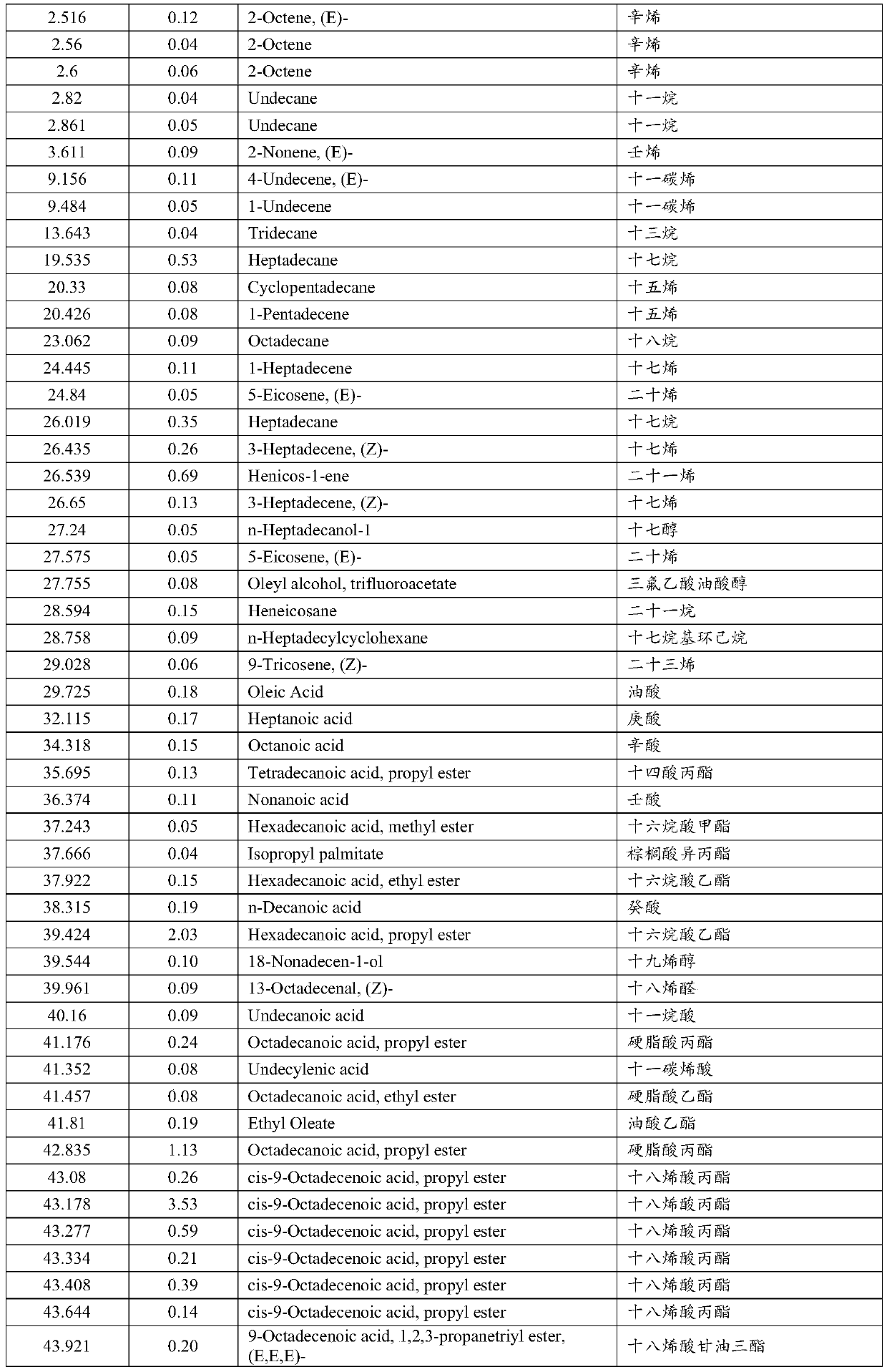

[0042] This example provides a method for analyzing the composition of hogwash oil hydrogenation products. The low-degree hydrodeoxygenation product A of hogwash oil is used as the analysis object (reaction temperature 320°C, hydrogen initial pressure 6MPa, alumina carrier catalyst), and the viscosity is reduced by heating ( 80 ℃), sampling 0.02ul, using one-dimensional gas chromatography-mass spectrometry (Shimadzu 2010 Plus-QP 2020) and modified polyethylene glycol capillary column (DB-FFAP 30m×0.25mm×0.25μm) samples were analyzed where,

[0043] The operating conditions of the gas chromatography are:

[0044] Carrier gas flow 40ml / min

[0045] Split ratio 40:1

[0046] The column specifications are: DB-FFAP 30m×0.25mm×0.25μm;

[0047] Injection port temperature: 240°C;

[0048] The heating program was as follows: firstly, the temperature was kept at 40°C for 5 minutes, then the temperature was raised to 100°C at a heating rate of 5°C / min, and the temperature was kept co...

Embodiment 2

[0062] This example provides a method for analyzing the composition of hogwash oil hydrogenation products. The low-degree hydrodeoxygenation product B of hogwash oil is used as the analysis object (reaction temperature 320°C, hydrogen initial pressure 6MPa, carbon carrier catalyst), and is diluted by m-xylene. Viscosity (addition amount is 10% of sample quality), sample 1.0ul, utilize one-dimensional gas chromatography-mass spectrometry instrument (Shimadzu 2010 Plus-QP 2020) and modified polyethylene glycol capillary column (DB-FFAP 30m ×0.25mm×0.25μm) to analyze the sample, where,

[0063] The operating conditions of the gas chromatography are:

[0064] Carrier gas flow rate 30ml / min;

[0065] Split ratio 30:1;

[0066] The column specifications are: DB-FFAP 30m×0.25mm×0.25μm;

[0067] Injection port temperature: 240°C;

[0068] The heating program is as follows: first, keep the temperature at 40°C for 5 minutes, then raise the temperature to 100°C at a heating rate of 5...

Embodiment 3

[0077] This example provides a method for analyzing the composition of acidified oil hydrogenation products, taking acidified oil moderate hydrodeoxygenation product C as the analysis object (reaction temperature 340 ° C, hydrogen initial pressure 8 MPa, carbon carrier catalyst), through heating (60 ℃), sampled 0.02ul, and utilized one-dimensional gas chromatography-mass spectrometry (Varian CP3800-300MS) and modified polyethylene glycol capillary column (HP-FFAP 30m × 0.25mm × 0.25μm) to sample analysis, where

[0078] The operating conditions of the gas chromatography are:

[0079] Carrier gas flow 30ml / min

[0080] Split ratio 30:1

[0081] The column specifications are: HP-FFAP 30m×0.25mm×0.25μm;

[0082] Injection port temperature: 240°C;

[0083] The heating program was as follows: firstly, the temperature was kept at 40°C for 5 minutes, then the temperature was raised to 100°C at a heating rate of 3°C / min, and the temperature was kept at a constant temperature for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionization potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com