Coal rock cutting dust generation experiment system and method

An experimental system, coal and rock technology, applied in measuring devices, instruments, particle size analysis, etc., to achieve the effect of realizing intelligence and improving experimental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

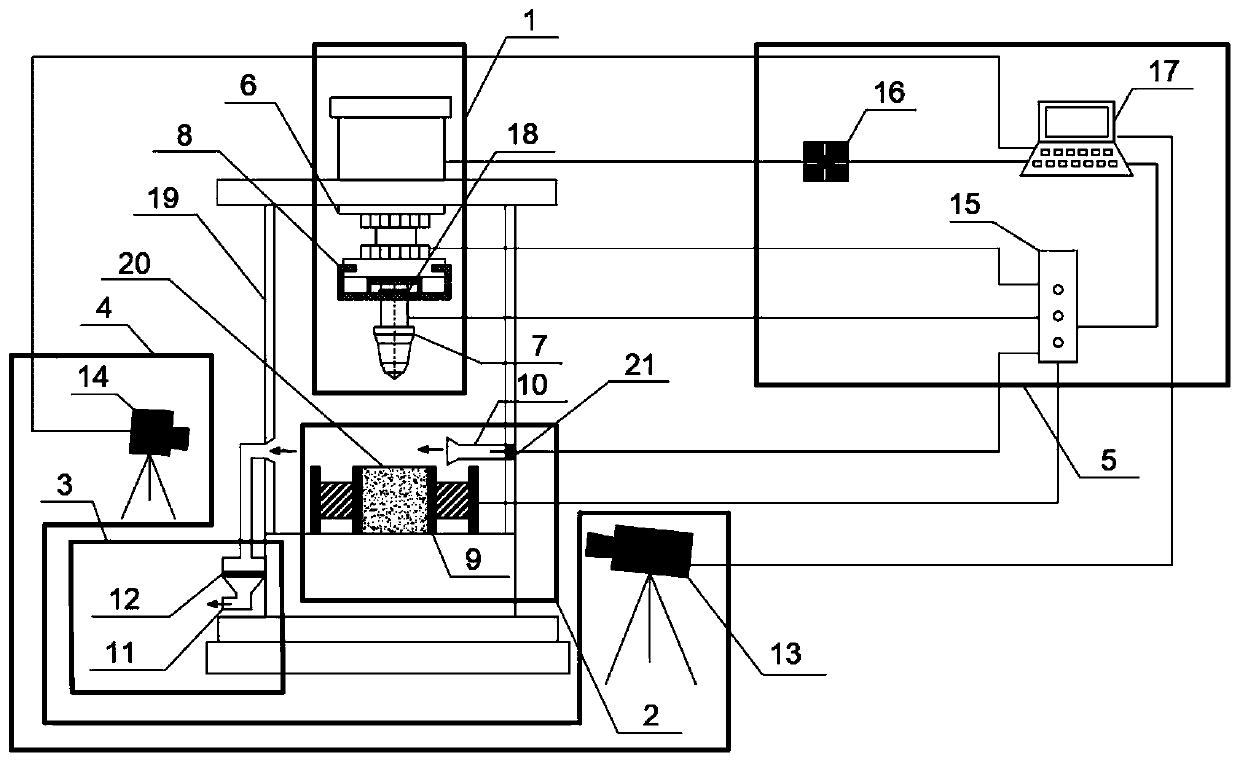

[0034] Such as figure 1 As shown, a coal rock cutting dust production experimental system includes a cutting part 1, an experimental condition regulation part 2, a dust collection part 3, a crushing form recording part 4, and a control and signal processing part 5.

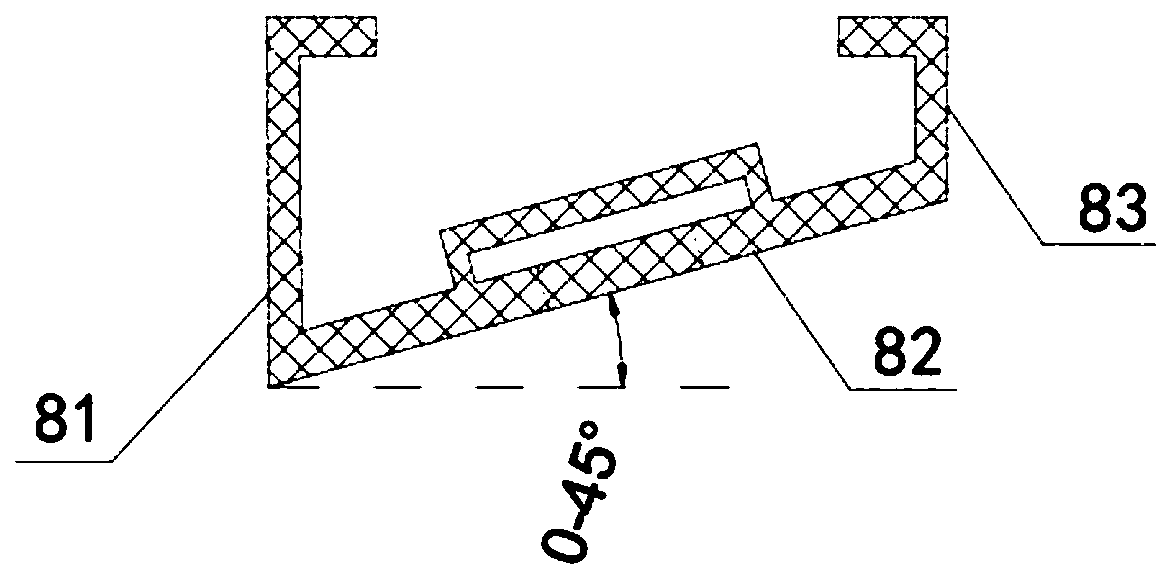

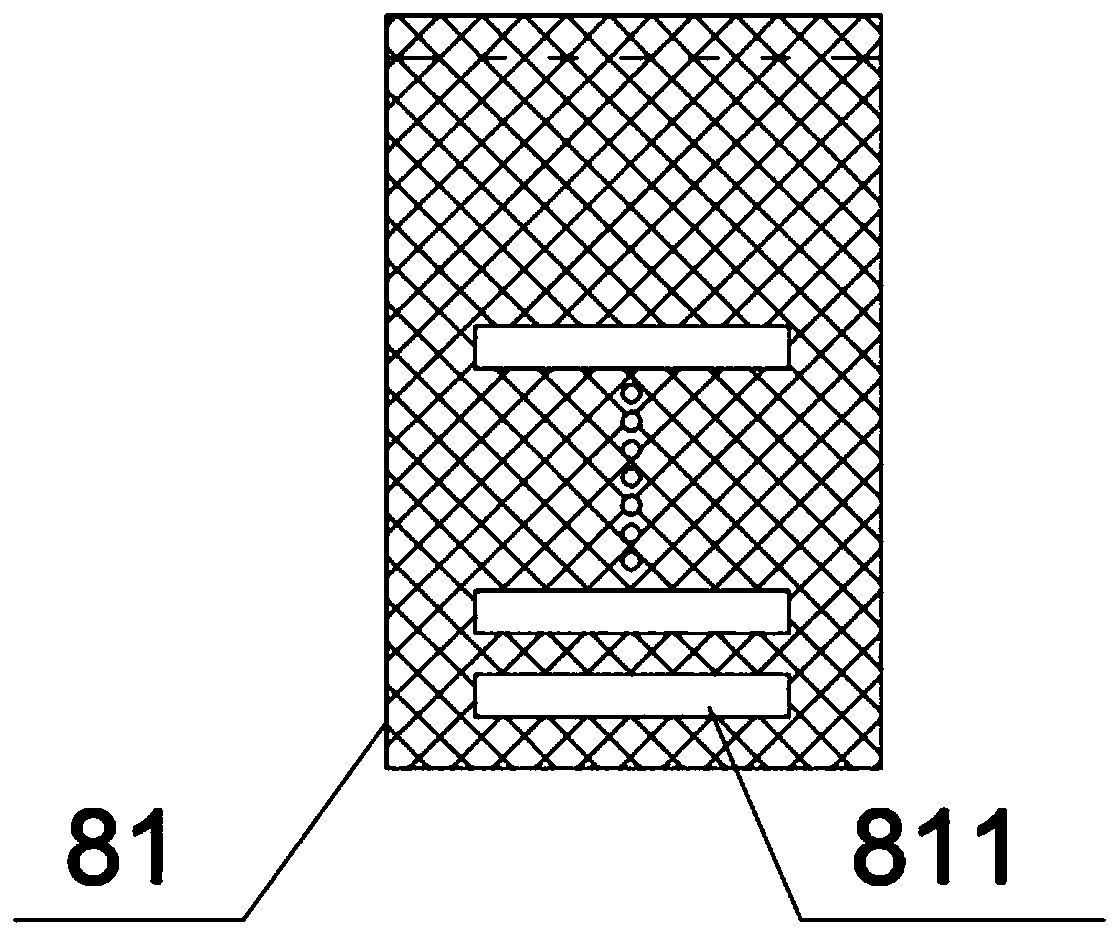

[0035] Such as figure 2 , image 3 and Figure 4 As shown, the cutting part 1 includes a loading device 6 moving vertically downward, a pick 7 and a fixed frame 8, and the pressure applied by the loading device 6 is transmitted to the signal collection device 15 as a pressure signal, and recorded in the upper position in real time. In the machine 17, the fixed frame 8 is installed under the loading device 6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com