Device for implementing external control and high-pressure automatic control

An external control, high-pressure technology, applied in the direction of fluid pressure actuating devices, servo motors, servo motor components, etc., can solve the problem of low after-sales pressure of construction machinery, and achieve the effect of reducing after-sales pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

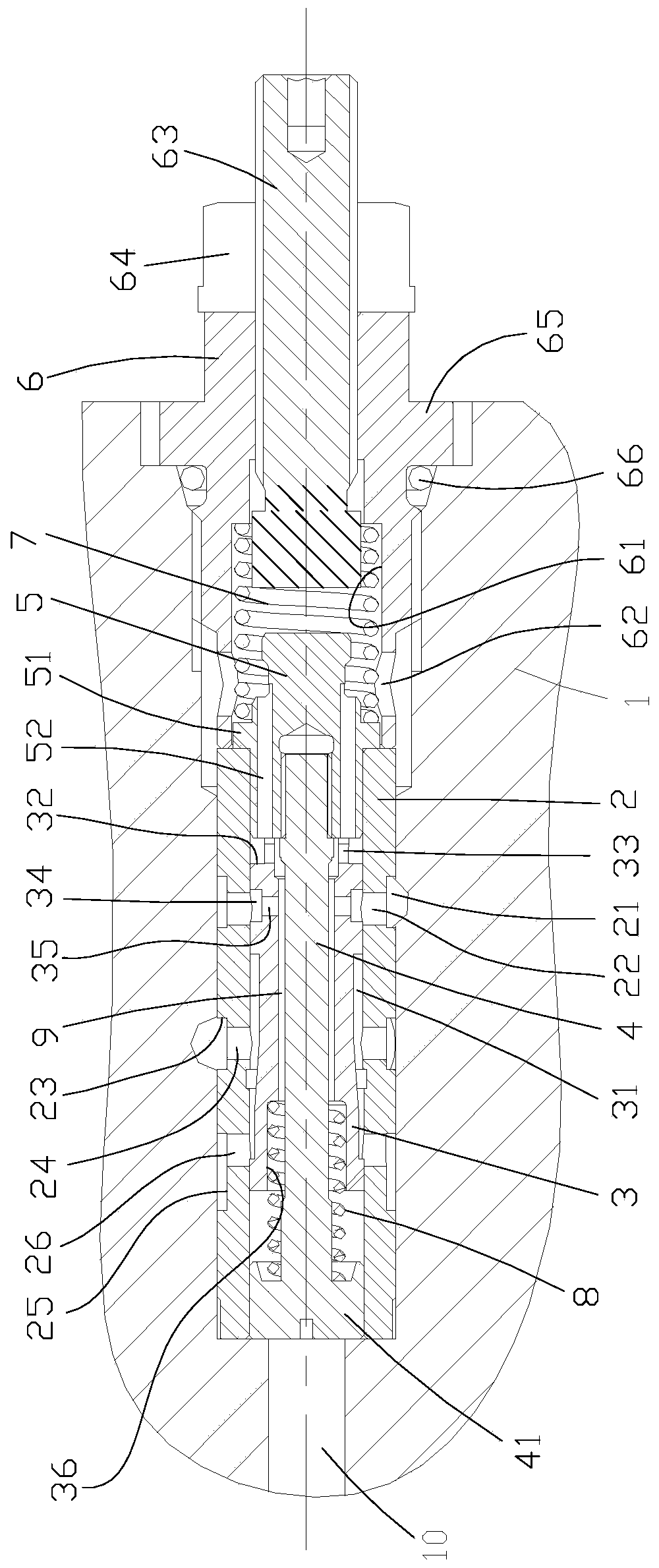

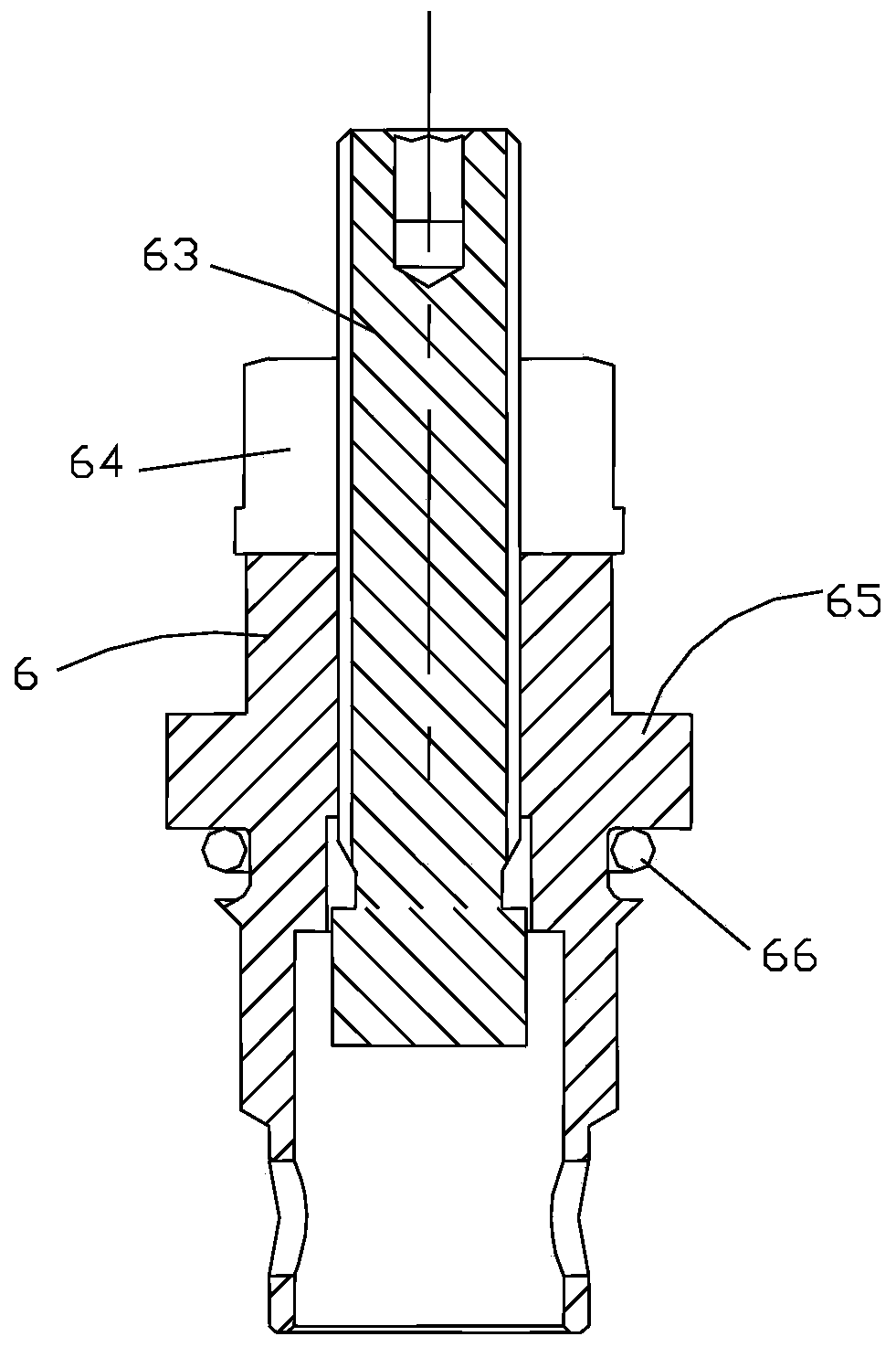

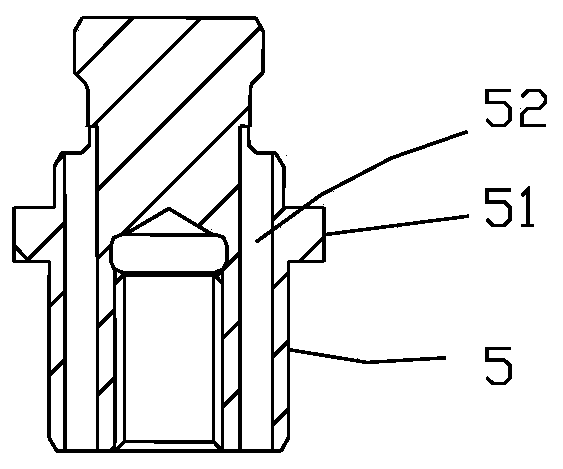

[0029] Example. A device that realizes external control and high-voltage automatic control, such as figure 1 As shown, including the base body 1, the base body 1 is provided with a blind hole, the bottom surface of the blind hole is provided with an oil inlet 10, the blind hole is provided with a tubular control valve sleeve 2, and the control valve sleeve 2 is provided with a tubular control valve Core 3, the control spool 3 is provided with a spool 4, one end of the spool 4 is provided with a spring seat 5, and the outside of the spring seat 5 (the side near the top of the blind hole) is provided with a limit seat 6, and the spring seat 5 and the limit An external control spring 7 is arranged between the seats 6, and the other end of the spool 4 protrudes from the control spool 3 and extends radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com