A kind of reaction bonded wet-laid polymer waterproof membrane and its preparation method

A technology of polymer waterproofing and wet laying, which is applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., and can solve the problems that affect the waterproof and sealing performance of the coil, cracks in the coil, stretching of the coil, etc. problems, to achieve good elongation, improve low temperature flexibility, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

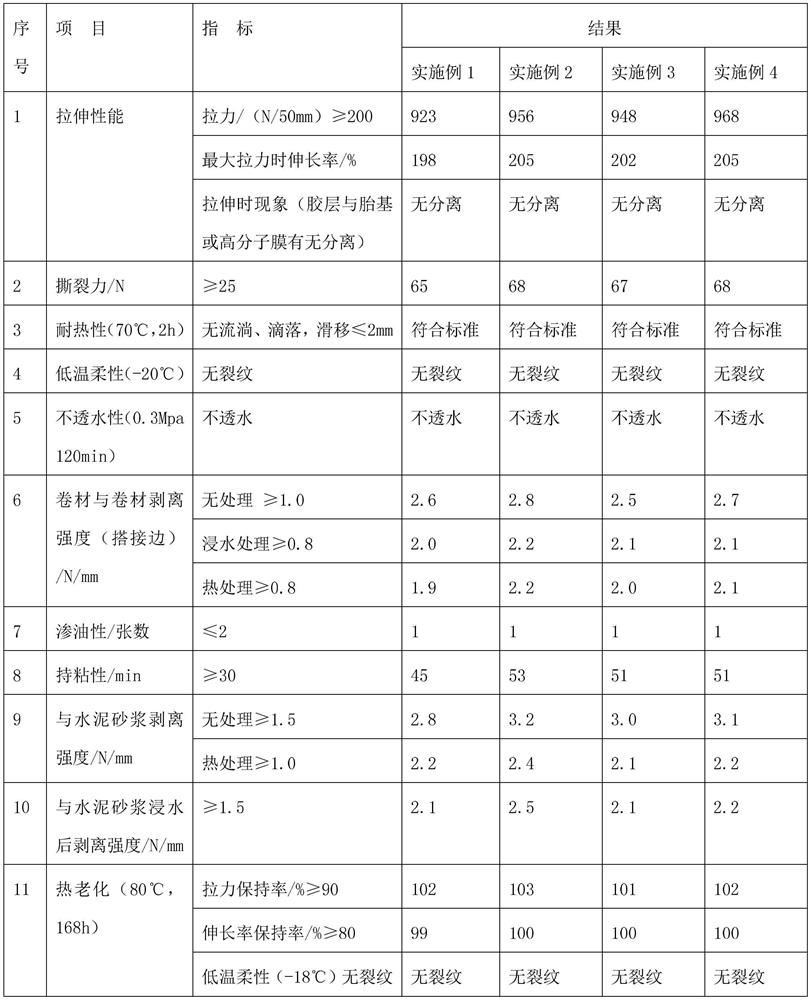

Examples

Embodiment 1

[0027] A reaction-bonded wet-laid polymer waterproof membrane, comprising a polyolefin thermoplastic elastomer base layer on the upper layer, a modified asphalt adhesive layer in the middle, and an isolation film protection layer on the lower layer, specifically:

[0028] The adhesive layer is made of the following raw materials: petroleum asphalt 55kg, tackifier coumarone resin 7kg, plasticizer dibutyl phthalate 5kg, antioxidant tris(2,4-di-tert-butylbenzene Base) ester 0.5kg, crosslinking agent vinyltriethoxysilane, 0.5kg, crosslinking accelerator 3-aminopropyltriethoxysilane 0.2kg, filler 20kg;

[0029] Polyolefin thermoplastic elastomer is made of the following raw materials: 5kg of polyisobutylene with a molecular weight of 10,000-100,000, 20kg of a copolymer of ethylene and octene with a molecular weight of 1,000-3,500, 3kg of ethylene-propylene rubber, 10kg of modified polypropylene, and antioxidant Di(dodecyl alcohol) thiodipropionate 1.2kg, anti-aging agent 2,6-di-ter...

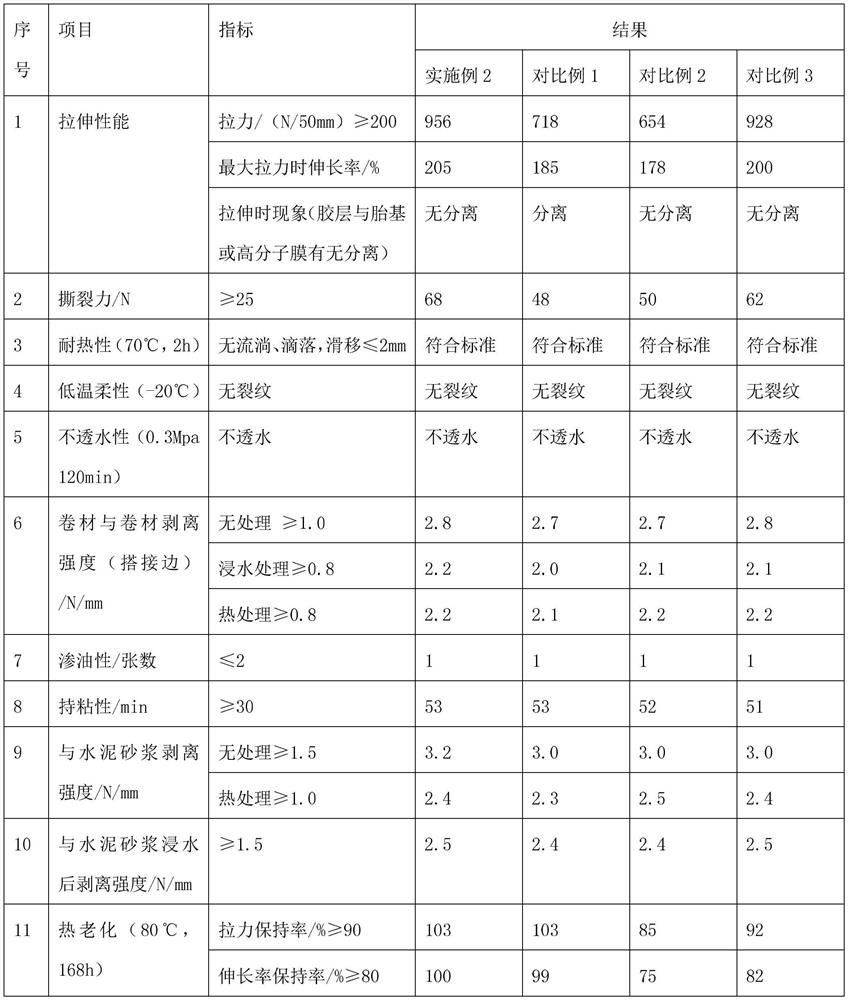

Embodiment 2

[0038] A reaction-bonded wet-laid polymer waterproof membrane, comprising a polyolefin thermoplastic elastomer base layer on the upper layer, a modified asphalt adhesive layer in the middle, and an isolation film protection layer on the lower layer, specifically:

[0039] The adhesive layer is made of the following raw materials: petroleum asphalt 58kg, tackifier coumarone resin 8kg, plasticizer trimellitate 8kg, antioxidant tris(2,4-di-tert-butylphenyl) 0.7kg of ester, 1.2kg of vinyl tris(β-methoxyethoxy)silane as a crosslinking agent, 0.5kg of 3-aminopropyltriethoxysilane as a crosslinking accelerator, and 25kg of filler;

[0040] Polyolefin thermoplastic elastomer is made of the following raw materials: 8kg of polyisobutylene with a molecular weight of 10,000-100,000, 25kg of a copolymer of ethylene and octene with a molecular weight of 1,000-3,500, 4.5kg of ethylene-propylene rubber, 18kg of modified polypropylene, antioxidant Agent thiodipropionate di(dodecyl alcohol) 1.6...

Embodiment 3

[0049] A reaction-bonded wet-laid polymer waterproof membrane, comprising a polyolefin thermoplastic elastomer base layer on the upper layer, a modified asphalt adhesive layer in the middle, and an isolation film protection layer on the lower layer, specifically:

[0050] The adhesive layer is made of the following raw materials: petroleum asphalt 59kg, tackifier coumarone resin 9kg, plasticizer epoxy soybean oil 7kg, antioxidant tris(2,4-di-tert-butylphenyl) phosphite 0.5~1kg, 1.0kg of crosslinking agent tri-tert-butoxyvinylsilane, 0.5kg of crosslinking accelerator 3-aminopropyltriethoxysilane, 26kg of filler;

[0051] Polyolefin thermoplastic elastomer is made of the following raw materials: 7kg of polyisobutylene with a molecular weight of 10,000-100,000, 22kg of a copolymer of ethylene and octene with a molecular weight of 1,000-3,500, 4kg of ethylene-propylene rubber, 18kg of modified polypropylene, and antioxidant Di(stearyl alcohol) thiodipropionate 1.8kg, anti-aging ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com