Production technology for producing solid organic fertilizer from anaerobic biogas residues

A production process and technology for organic fertilizers, applied in the field of organic fertilizers, can solve problems such as low curing efficiency, inability to sell, waste of resources and the environment, and achieve the effects of reducing cultivation costs, lightening farmers' burdens, and short fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

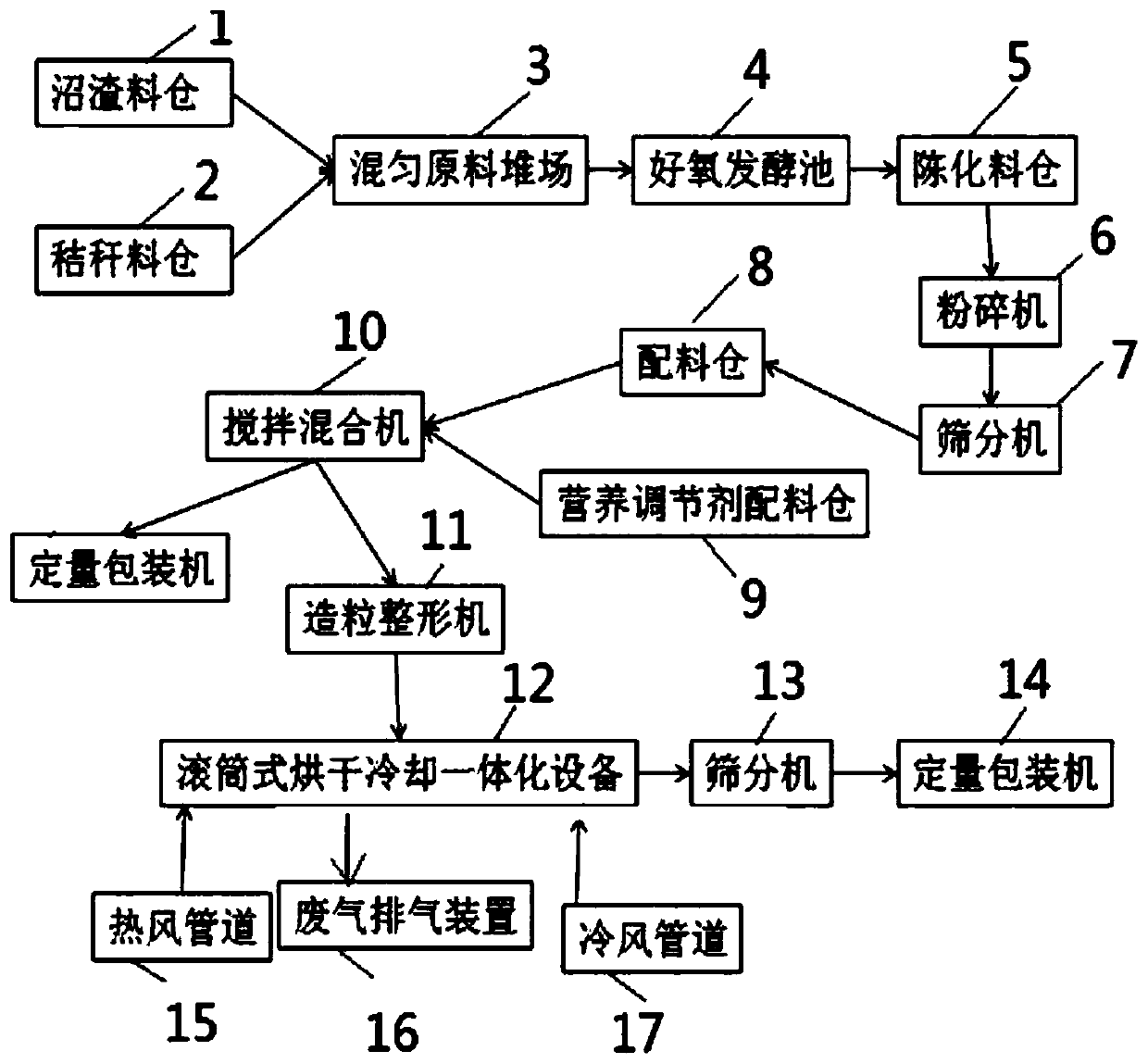

[0037] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0038] A production process utilizing anaerobic biogas residue to produce solid organic fertilizer, comprising the following steps:

[0039] (1) Mixing of raw materials

[0040] After the biogas residue produced by anaerobic fermentation of organic matter is dehydrated, the moisture content of the biogas residue is 70-75%, and the moisture content of the mixed raw material is 60-65% by adding crushed straw with a moisture content of 10-20%; The volume ratio of biogas residue to straw is 4-6:1;

[0041] The mixed raw materials are stacked in the mixed raw material stockpile, and the fermented bacteria are added to form a mixed material, which is aged for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com