Device for waste heat recovery and smoke moisture removal combined wastewater treatment

A technology for waste water treatment and waste heat recovery, which is applied in the direction of heating water/sewage treatment, gaseous waste water treatment, waste gas exhaust device, etc. Increase the dust content of the air, increase the heating area, and realize the effect of cascade utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

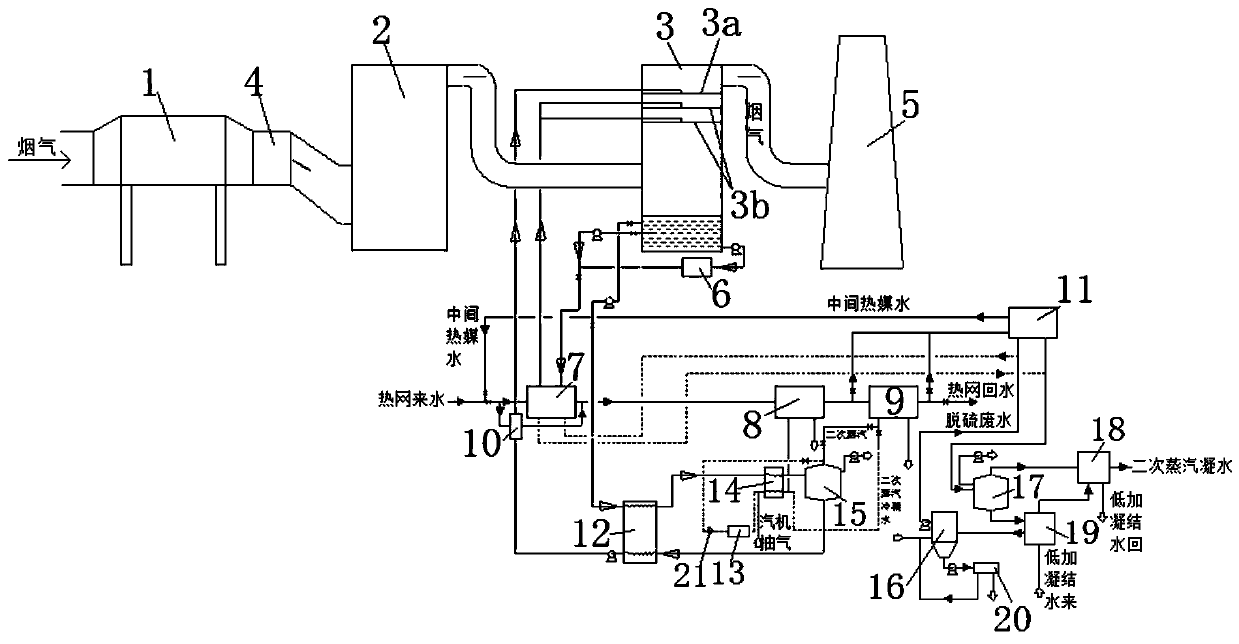

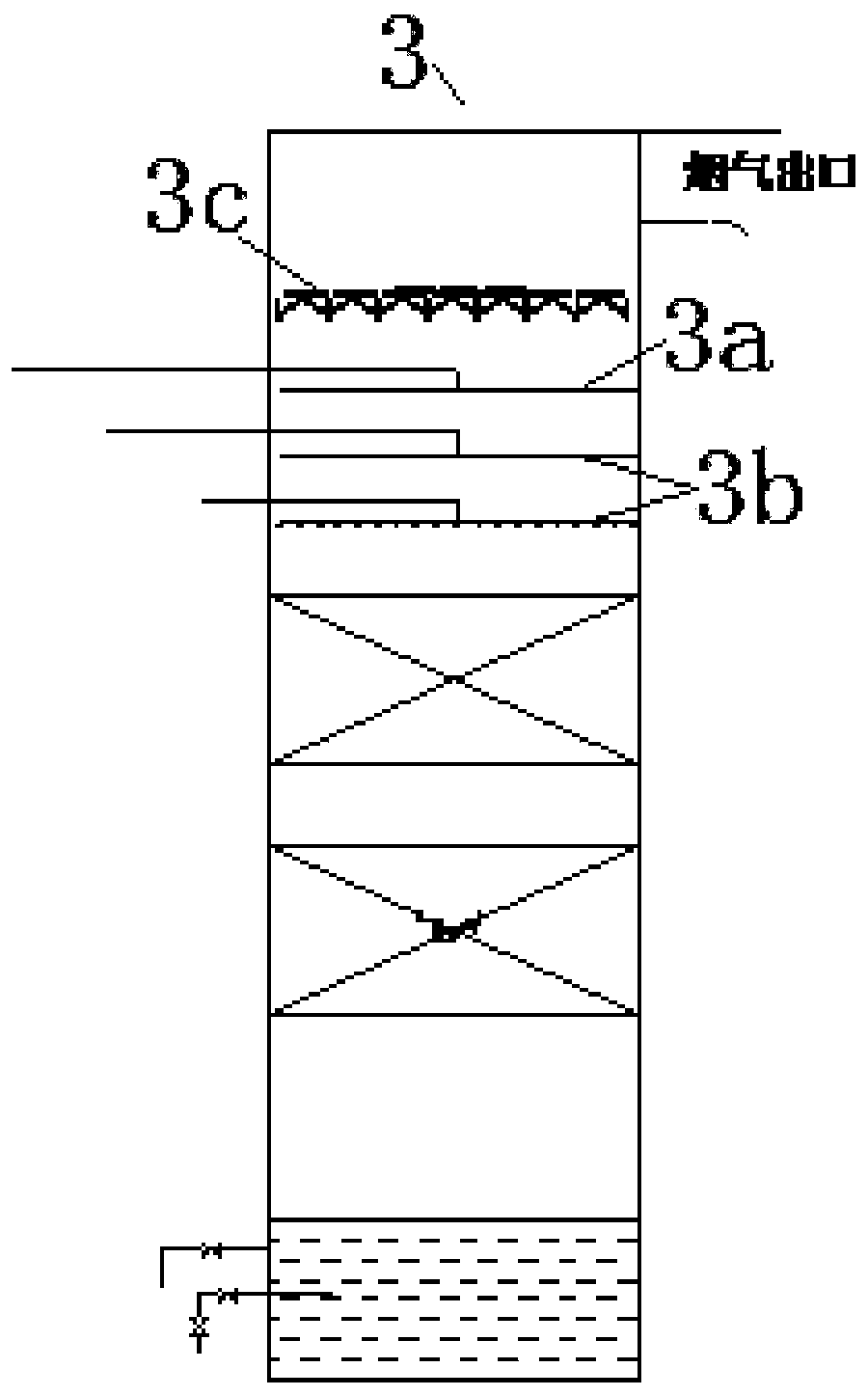

[0042] This embodiment provides a device for waste heat recovery and whitening combined with waste water treatment, such as figure 1 , 2 , 3 and 4, the absorption heat pump system includes a dust removal unit 1, an economizer 4, a desulfurization unit 2, an absorption unit 3, and a chimney 5 connected in sequence, and also includes a first circulation loop and is arranged on the first circulation loop The first heat exchanger 7, the liquid inlet end of the first circulation loop is communicated with the bottom of the absorption unit 3, and the liquid outlet is communicated with the upper part of the absorption unit 3; in this embodiment, the dust removal unit 1 is an electric dust collector, saving The coal device 4 is a low-temperature economizer, and the desulfurization unit 2 is a desulfurization tower; the absorption unit 3 can be an absorption tower, and the absorption tower can be an empty tower or a packed tower, and when it is a packed tower, the packing can be single-...

Embodiment 2

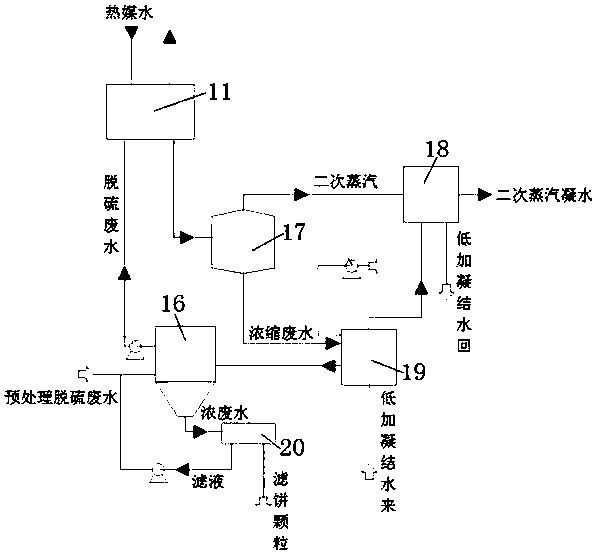

[0060] This embodiment provides a device for waste heat recovery and whitening combined with waste water treatment. On the basis of the above embodiment 1, it also includes a condenser 18, which communicates with the secondary steam outlet on the upper part of the waste water flash tank 17. The condenser 18 also Communicated with the waste water cooler 19, so that the heat exchange medium from the raised temperature in the waste water cooler 19 enters the condenser 18, and exchanges heat again with the secondary steam from the waste water flash tank 17;

[0061] Further, it also includes a second heat exchanger 8 and a third heat exchanger 9 connected in sequence, and the second heat exchanger 8 is also connected with the first heat exchanger 7, so that the incoming water from the heating network passes through the first heat exchanger in sequence. 7, the second heat exchanger 8 and the third heat exchanger 9 to form the return water of the heat network; the second heat exchang...

Embodiment 3

[0065] This embodiment provides a device for waste heat recovery and whitening combined with waste water treatment. On the basis of the above-mentioned embodiment 1 or 2, it also includes a first pump, which communicates with the waste water flash tank 17, and is used to make the waste water flash tank 17 It is in a negative pressure state and controls its internal vacuum degree; that is, in order to ensure that the heated wastewater can be flashed and concentrated, the low temperature phase change concentration system needs to be equipped with a vacuum pump (that is, the first pump), the vacuum pump and the wastewater flash tank and condensation The condenser is connected in series and located behind the condenser. The secondary steam is cooled in the condenser first. During the cooling process, a phase change occurs to generate a negative pressure, which can maintain the negative pressure of the system itself. However, a vacuum pump is required to start the system and maintain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com