A kind of preparation method of bisfluorosulfonimide alkali metal salt

A technology of bisfluorosulfonimide base and bischlorosulfonimide base is applied in directions such as nitrogen and non-metallic compounds, sulfamic acid, etc., to solve the problem of sublimation residues, reduce preparation costs, and simplify purification steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of bisfluorosulfonimide alkali metal salt, the steps are as follows:

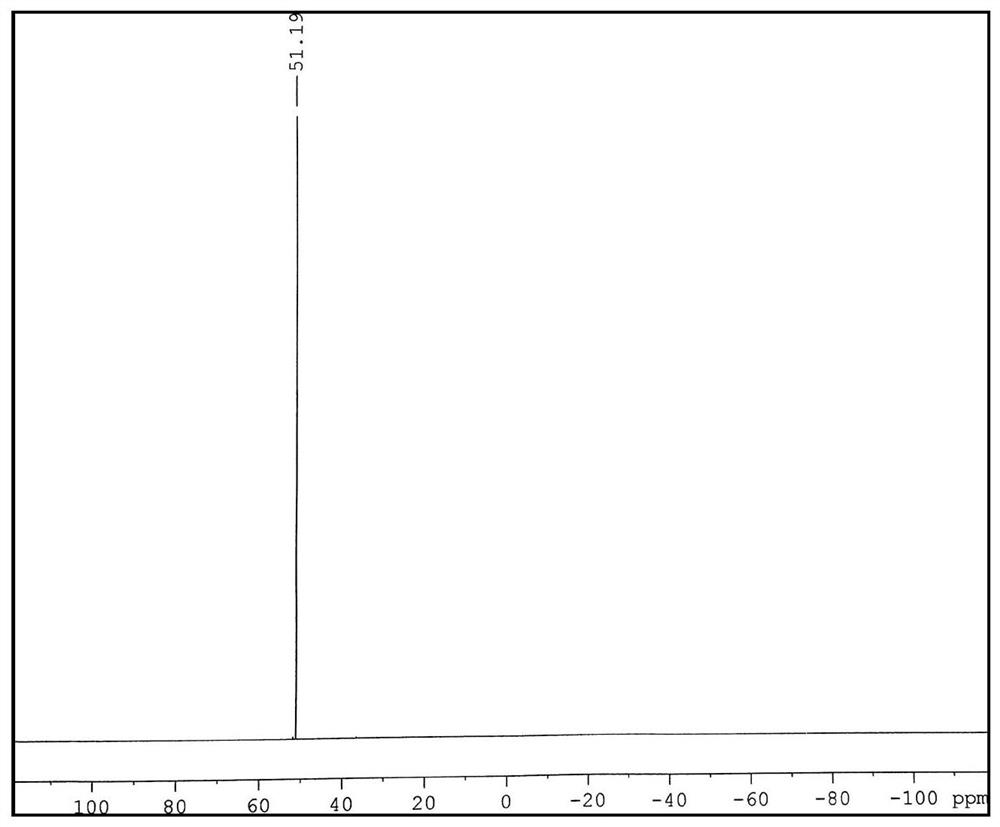

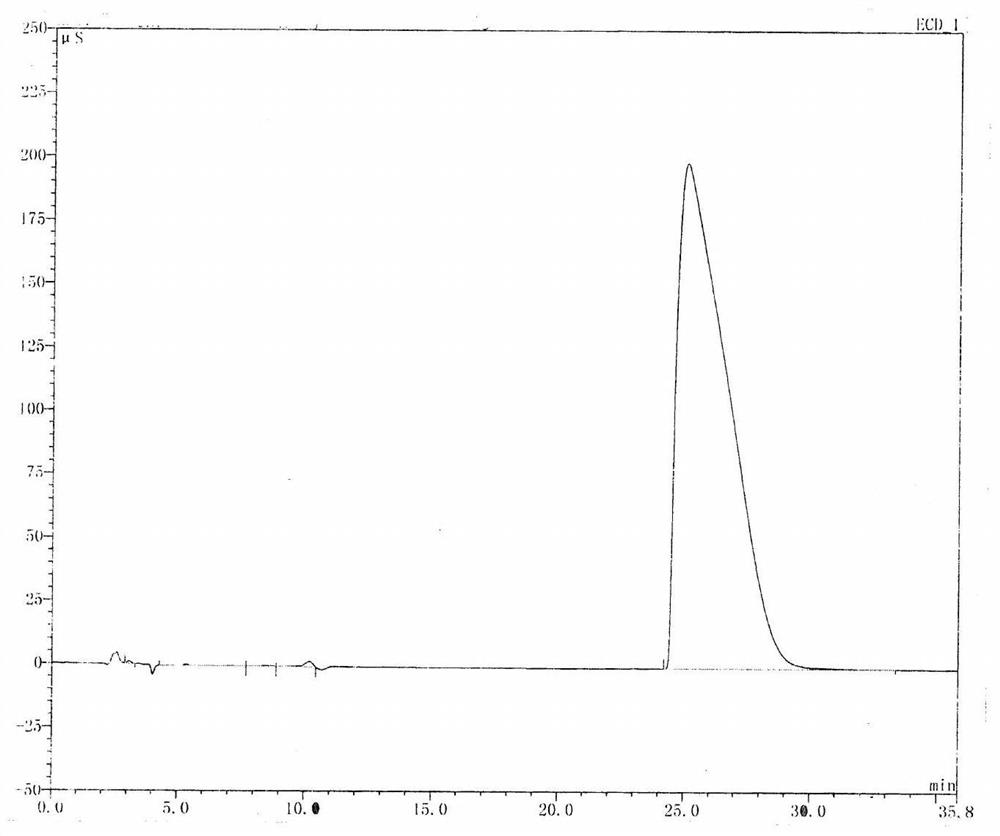

[0037](1) Under the protection of dry nitrogen, add 0.2L dimethyl carbonate and 115g dichlorosulfonimide potassium salt into a 1L three-necked flask. After stirring and dissolving, 148 g of dried bismuth fluoride was added at room temperature, and stirred at room temperature for 24 hours. After the reaction, the system was moved to a glove box with a water content lower than 1 ppm to filter and remove excess bismuth fluoride. The filtrate was evaporated to dryness with a rotary evaporator to obtain a light yellow solid mixture;

[0038] (2) Under the protection of dry nitrogen, the above light yellow solid mixture was dissolved in 120 g of absolute ethanol in a jacketed flask with a cooling device, and the temperature of the solution was kept not higher than 20° C. After stirring and dissolving for 4 hours, it was transferred to a glove box for filtration, and the filtrate wa...

Embodiment 2

[0040] The preparation method of bisfluorosulfonimide alkali metal salt, the steps are as follows:

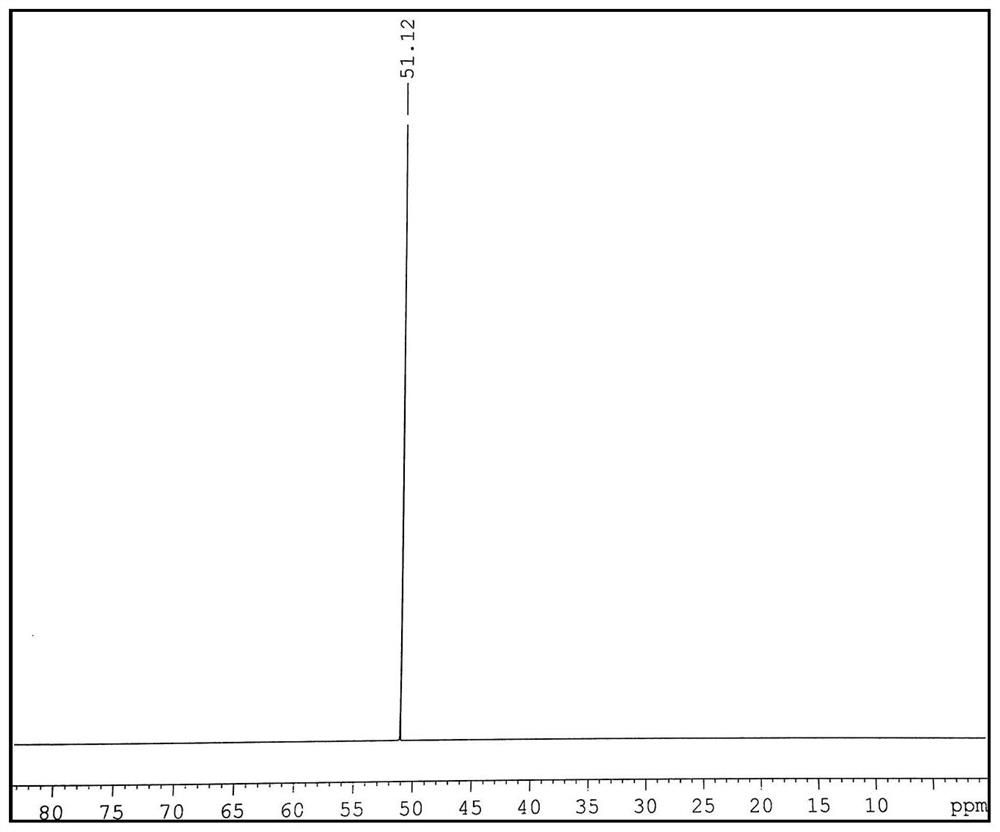

[0041] (1) Under the protection of dry nitrogen, 0.2 L of acetonitrile and 117.6 g of lithium dichlorosulfonimide were added to a 1 L three-necked flask. After stirring and dissolving, 64 g of dry antimony fluoride was added at room temperature, and the reaction was stirred at room temperature for 24 hours. After the reaction, the system was moved to a glove box with a moisture content lower than 1 ppm to remove excess antimony fluoride by filtration. The filtrate was evaporated to dryness with a rotary evaporator to obtain a light yellow solid mixture;

[0042] (2) Under the protection of dry nitrogen, the above light yellow solid mixture was dissolved in 200 g of anhydrous toluene in a jacketed flask with a cooling device, and the temperature of the solution was kept not higher than 20° C. After stirring and dissolving for 4 hours, it was transferred to a glove box for filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com